According to my experience, I estimate that replacing the alternator solves 95% of all charging system failures. If that’s true, what happens in the remaining 5% of charging system failures that results in customer comebacks? To explore charging system comebacks in greater detail, let’s consider a hypothetical case involving a remanufactured alternator that you’ve just installed on a 2008 Toyota Tundra. A few days ago, it left your shop with a happy owner and now it has returned with the battery warning light glaring in the owner’s face. Let’s begin by reviewing a few charging system basics.

Voltage Testing

Most Toyota charging systems integrate their voltage regulators into the alternator assembly. While charging voltage specifications vary according to application, the voltage regulator generally adjusts battery-charging voltage according to ambient air temperature. For example, at 70° F, the voltage regulator charges the battery at approximately 14.2 volts. As underhood or ambient temperatures increase, the charging voltage is reduced to about 13.8 volts or less to prevent boiling the water from the battery electrolyte. During cold weather, charging voltage can increase into the 15-volt range to compensate for reduced chemical activity in the battery in sub-freezing temperatures. In any case, consult your service data before assuming that an apparently low or high charging voltage is incorrect for the system in question.

Battery Testing

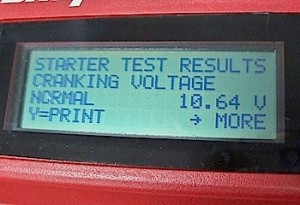

According to Toyota, a dynamic battery state of charge (SOC) and state of health (SOH) test can be performed with the aid of a simple voltmeter. First, turn off all accessories such as exterior lighting, HVAC blower and high-amperage components like the rear-glass defogger. Next, disable the fuel pump and crank the engine with a voltmeter connected in parallel with the battery terminals. If the cranking voltage dips below 9.6 volts, recharge or replace the battery as required before proceeding with the alternator test. See Photo 1.

I’ve found that if the battery is discharged and the battery core is at room temperature, the following recharging tips can be indicative of a battery’s state of health. 1. Charging amperage will rapidly decrease and charging voltage will rapidly increase on a badly sulfated battery. 2. The initial charging amperage should be high on a good battery. 3. Initial charging amperage gradually decreases as the charging voltage gradually increases on a good battery. 4. A battery with a weak cell will not achieve a desired charging voltage of 14.2 volts at room temperature. 5. Remember that many “smart” battery chargers will increase voltage in excess of 15 volts as they enter a “desulfation mode.” The smart charger might also enter a 13.2-volt maintenance mode when desulfation and recharging are completed. See Photo 2.