Timing chain failures can be like genetic abnormalities for heart diseases. In some people, the faulty genetic code does not cause any problems. In others, it can cause fatal heart attacks due to other contributing factors. Some doctors call these comorbidities.

The AJ126 V6 and AJ133 V8 engines found in many Jaguar and Land Rover cars and trucks follow the same patterns, with some engines suffering catastrophic timing chain failures, while others do not have any issues. In both the V6 and V8, the engine uses independent chains for each bank of cylinders. The engine does not use hydraulic lifters. On top of the valve stems are buckets that are a specific height that create a specific clearance between the bucket and the camshaft.

What is the deal with the timing chains? If you Google “Jaguar V6 or V8 timing chains,” you will likely run across a website about a class action lawsuit. The website will describe the condition as an engine misfire, and rattles and metal debris found in the oil sump. The lawyers say that the problem might cost as much as $20,000 to repair. The cause of the failure is the guides and tensioners.

When a guide and tensioner fail, it induces timing chain slap that causes the chain to jump on the sprockets. Ground zero for the problem is the small area where the piston of the tensioner makes contact with the guide.

The best-case scenario is that the timing will jump and cause misfires. The worst case is that the timing jumps so far that the valves will crash into the piston, and the valves and camshaft will be damaged. When this happens, the chain for a bank will typically come off the sprocket, and that bank will cease to function. However, the other bank may continue to run on three or four cylinders. On some engines, the bolt for a guide can back out and cause a similar failure. But, there is also the possibility of timing chain stretch and crankshaft and camshaft correlation codes on higher-mileage engines.

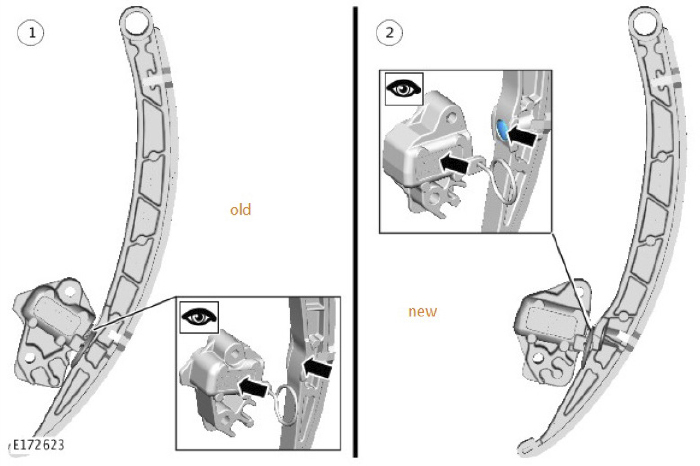

Is there a fix? Yes and no. Most of the engines with failure are from the 2012-2015 model years. The original guide is cast aluminum with a plastic surface for the chain.

The hard steel piston of the tensioner pushes on the back of the soft aluminum guide. When the steel piston causes wear on the guide, that can cause a divot to form. Eventually, the tolerances will become too great between the tensioner and guide, which will cause a loss of tension in the chain.

Jaguar and Land Rover did improve the guides with a small steel pad on the back of the guide on later models. Also, engineers made changes to the angle where the tensioner makes contact with the guide. Many aftermarket timing chain kits have duplicated the design.

Another change Land Rover and Jaguar made to these engines is a wider chain with a different tooth pattern and pitch. The width was upgraded to 8mm from 6.35mm. If you plan to update the chain, you will have to change the sprockets.

The Timing Chain

Each timing chain has a fixed timing chain guide which is secured to the cylinder block with three shoulder bolts. A tensioner arm is fitted to each timing chain which can rotate around a shoulder pivot bolt. Each timing chain has a mechanical tensioner operated by spring tension to apply a controlled tension to the timing chain. This maintains the timing chain at the correct tension and allows for and dampens backlash in the chain tension due to engine deceleration. The timing chains and tensioners are maintenance-free components.

Each timing chain tensioner has a hole that allows for the locking of the tensioner to facilitate the removal of the tensioner arm, guide or camshaft timing chain. The tensioner plunger can be pushed back into the housing, and a pin can be inserted to lock the tensioner in the retracted position. The timing chains are lubricated with engine oil from jets located at the top of the crankshaft’s sprocket. These are small tubes or feeds with jets at the end. The tubes can be damaged if the guides break.

VCT

The V6 and V8 have vane-style variable camshaft actuators. The oil travels from the caps to the center of the hollow camshaft. At engine startup, once the engine oil pressure in the camshaft is sufficient to open the inlet check valve, engine oil flows across the spool valve, through the advance and retard check valves, and into the advance and retard chambers. During every start, the engine control module signals the variable camshaft timing (VCT) solenoid to move the spool valve into the sleeve and connect the lock pin to the inlet oil pressure. The inlet oil pressure causes the lock pin to retract from the inner plate and unlock the rotor assembly and camshaft from the sprocket housing.

If you are getting a rattle at startup, it could be because the pin is damaged or there is an issue with oil pressure not making it to the spool valve and chambers in the actuator. Oil travels from the bearing caps through the hollow camshaft. There is a screen inserted into the end of the camshaft behind the actuators. If you are replacing the actuators as part of a timing chain service, check this screen for debris.

If you can’t isolate the rattle to the actuators, a common misdiagnosis is a noise coming from the supercharger. This is caused by a spring-loaded coupler that is between the input shaft and the supercharger’s gear drive. The spring can break and cause a rattle like the VCT actuators. With the high-mileage VCT actuators, it is always a good practice to replace them when the chain is replaced.

Tips

The crankshaft pulley bolt on most engines is a left-hand thread. You can determine if the bolt has a left-hand thread if it has “12.2” cast into the head. This is a very tight bolt that will require much force to remove. There is a special tool that can counter-hold the crankshaft pulley so the bolt can be removed. When removing the pulley from the crankshaft, take extra care not to damage the left-hand threads in the crankshaft. Finding a left-hand tap and die or thread chaser is impossible for this size. Damaging the threads might require a new crankshaft. There is a special tool available for this procedure.

The special tool kit for these engines includes a wrench to pre-tension the actuators using a torque wrench. This ensures when the tensioners are released, the timing marks do not shift. If the tool is not used along with the fixtures to lock the camshafts, you will notice a shift of two or three teeth when the tensioners are released and the engine is turned over. If this is not corrected, it will cause codes when the engine is started.

To remove the valve covers, you will need to remove the fuel injectors. The injectors are challenging to remove and can be impossible to remove from the bore. Removal will require a slide hammer with an adapter that grabs the lip of the injector. Trying to twist the injector might break the injector.

The class action lawsuit says the average timing chain failure happens between 80,000 and 150,000 miles. But, some owners never experience these problems. What is the comorbidity that dooms the most timing chain failures? It’s oil changes. If the oil is not changed or the wrong oil is installed, it can cause issues when the engine ages.