Mercedes-Benz uses two different adjustable suspension systems in its vehicles – Airmatic and Active Body Control (ABC). Airmatic, as the name implies, is its air suspension system which we discussed back in April of this year. ABC uses hydraulic fluid at tremendous pressures to actively change the stiffness of the springs inside the shock assemblies, changing vehicle dynamics and ride height. This can be done automatically based on sensor inputs and module programming, or at the push of a button located near the shifter.

It’s easy to visually tell the difference between an Airmatic and ABC system – it’s all in the lines. Airmatic shocks will have a small diameter air line which connects near the top of the air spring, maybe 1/4” ID. ABC shocks will have a larger diameter hydraulic line which connects to the spring assembly, around 1/2” – 3/4” OD. Performing a system scan to check for codes will also show you which type of suspension is installed.

But, in my years as a Mercedes technician, I learned a general rule – if it has a V12 engine, it has ABC. So, if you have an S600, S65 AMG, CL600, CL65 AMG, SL600, SL65 AMG, and so on, you’re working on an ABC-equipped vehicle. ABC was available as an option on certain vehicles, but it cost thousands of dollars and it wasn’t as desirable as other build sheet options.

Customer States

Almost all ABC complaints will be accompanied by a “Drive Carefully” or “Visit Workshop” message appearing in the Driver Information Center (DIC). The DIC is the small display which is located between the gauges in the instrument cluster. These messages will be in white or red depending on the severity of the issue which was detected by the system. Red means urgent, and it can be dangerous to drive the vehicle in this condition, especially at highway speeds.

If the ride height of any of the four corners should fall to an unacceptable level, the ABC system will display a “Too Low” warning in the DIC. The customer should pull over immediately, or risk damage from the tires coming into contact with the wheel wells. There is also risk of an accident if a tire wedged itself in place inside the wheel well. The inconvenience of having the vehicle towed is much better than the risk of an accident, or the cost of other components which could be damaged by putting off the repair.

Now let’s take a closer look at the individual components of the ABC system, how they function, and what happens as they wear out or fail.

ABC System Components

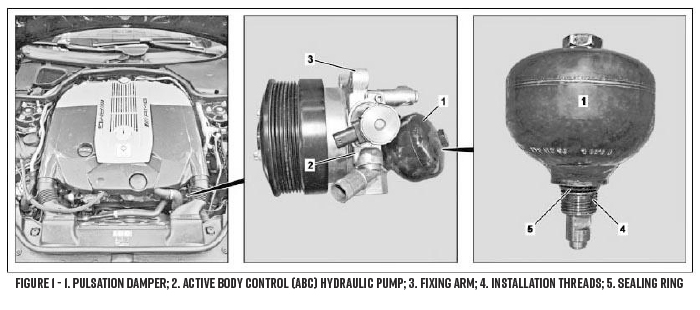

Starting at the heart of the system, we have the ABC pump (Figure 1). In most cases, the ABC pump will be incorporated into the power steering pump. This is known as a tandem pump. It’s worth noting that while the two pumps may share the same pulley and shaft, they are completely separate components in every other way. One may fail, while the other is fully functional, but they must both be replaced since they are a singular unit.

The pump is lubricated by the hydraulic fluid, so it’s critical that it never be allowed to run dry. If it does run dry, it will quickly destroy itself, shedding debris and shavings into the rest of the system. That debris can cause damage to accumulators, valve blocks, and other expensive components. This doomsday scenario does happen, but it’s not the most common. In many cases, a failing pump will simply lose its ability to supply adequate pressure and volume to keep up with system demand, and the issue would get worse over time.

A failing pump is typically easy to diagnose. “Drive Carefully” or “Visit Workshop” message will appear in the instrument cluster shortly after engine startup, and it will stay on. The car will not raise on command when the button is pressed, and a code scan will indicate inadequate system pressure.

The hydraulic fluid is the lifeblood of the ABC system. This is highly specialized fluid, and it is expensive. I mentioned earlier that the fluid is pumped at tremendous pressures, but just how high are we talking? The high pressure check valve regulates system pressure at 190 bar (2756 psi) on the pressure side, and the return pressure check valve regulates the return side pressure at 10 bar (145 psi). That’s a lot of pressure, and it can place a lot of strain onto the hydraulic hoses and lines. If a hose were to blow out, it would cause the fluid to leak out quickly and the strut would collapse. This is usually accompanied by a loud BANG, followed quickly by “Drive Carefully” message on the instrument cluster. The customer may also notice a dark fluid leaking from under the vehicle, or that they’ve needed to add fluid to the reservoir.

Regular fluid replacement is the best way to keep on top of system condition, and it might save the customer an even more costly repair if an issue is caught early on. Reference the maintenance schedule for the application you’re working on for replacement intervals. If you can’t find a replacement interval, we would recommend hydraulic fluid service every 2-3 years, similar to the interval of brake fluid.

Shock absorbers are used on all four corners to connect the wheels to the chassis. A coil spring inside supports the weight of the vehicle assembly and absorbs vibration. Hydraulic fluid is pumped into the unit to stiffen the coil spring and control ride height.

Valve blocks are used to direct the hydraulic fluid in and out of the struts based on control module commands. They don’t fail very often, but if they do it’s very likely they were killed by contaminated fluid. Debris and contaminants will build up on the valve seats causing them to leak, or the O-rings will deteriorate. If the vehicle drives normally, but one corner sags when parked overnight, the valve block is a likely culprit. This is because the fluid is escaping past the leaky valve seats, and returning to the reservoir. It’s possible that this symptom could be caused by a fluid leak, so be sure to inspect the entire system for leaks.

Pressure accumulators are used to regulate system pressure to the struts. These black spheres contain nitrogen gas behind a rubber membrane. Hydraulic fluid travels in or out of the accumulator based on pressure differential. They’re able to take some of the load off of the hydraulic pump, allowing the system to respond quickly and fill the struts.

How do you know if an accumulator has gone bad? Observe the fluid level in the reservoir. A faulty accumulator will hold onto more fluid than normal. When the system depressurizes, the fluid will be pushed back to the reservoir, causing it to overflow. Look for a difference in fluid level when the engine is running VS when it is shut off. This will indicate the overall health of the accumulators. You can also visually inspect the rubber membrane. Depressurize the system and remove the accumulator, then use a non-pointed tool to avoid damaging or tearing the membrane.

Some applications will have a pulsation dampener installed near or on the hydraulic pump (Figure 1). This dampener will be similar in construction to a pressure accumulator, but much smaller in size. If you feel a buzz or vibration coming from the vehicle, usually at lower engine or vehicle speeds, both in and out of gear, the vibration dampener is the likely culprit.

Tech Tips

Whenever you’re working with an ABC system, think CLEAN. Thoroughly clean the area around any connection points before starting any type of repair. Close off any open connections to keep contaminants out. Ensure absolute cleanliness when pouring the hydraulic fluid into the reservoir.

Visually inspect the sealing surfaces and fittings for damage before assembly. Use your best judgment, but we recommend always replacing O-rings and sealing rings. Center the hydraulic lines and hoses in place without any tension on them, and thread them in as far as you can by hand. And, of course, ALWAYS observe the OEM tightening specifications and torquing procedures.