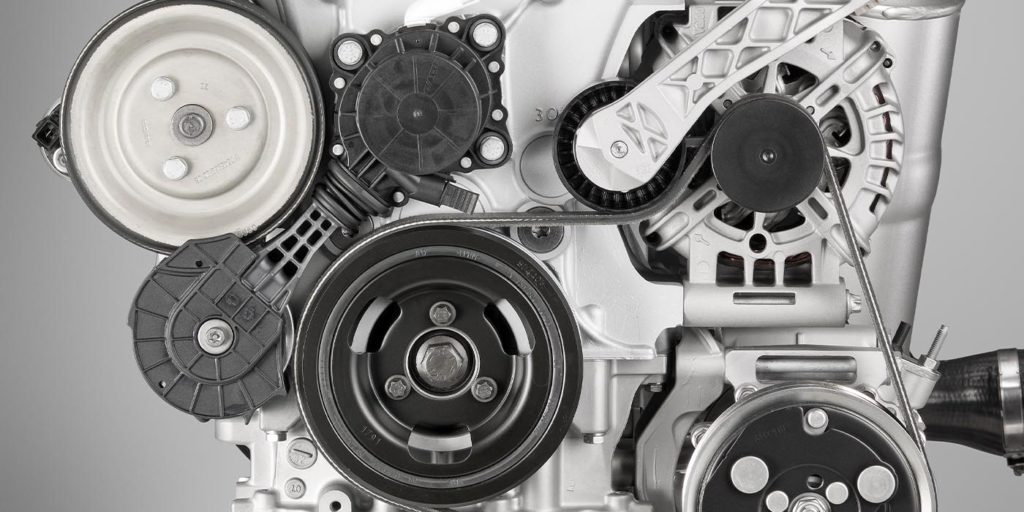

One of the more interesting drive belt arrangements can be found on the Mini Cooper with the 1.6L Tritec engine. The new four-cylinder engine had a surprise for technicians when it came time to replace the water pump.

The water pump has what looks to be a belt around the pulley but is actually rubber bonded to the outside. The water pump is turned by a metal wheel driven by the crankshaft pulley – this wheel is what transfers the motion of the crankshaft to the water pump.

This innovative tensioner is called a friction wheel drive system. The tensioner is able to disengage the water pump until the engine has reached a specific temperature. On a cold engine that is turned off, the tensioner will feel a little loose and you might be able to turn the pump by hand.

When the engine management system engages the water pump a small electric motor inside the tensioner changes the length of tensioner. The wheel is pulled onto the back of the belt on the crankshaft and water pump pulley.

If you need to replace the belt or water pump, you need to disengage the tensioner. To release the tension, a tab first needs to be pulled out. The main problem that can occur is the rubber on the outside of the water pump can wear out or come off the wheel. This can cause noise and possible damage to the tensioner and even to the back of the drive belt. If the water pump or wheel on the tensioner seizes, it can cause a flat spot on the pulley and can also cause damage to the drive belt. Some aftermarket suppliers have improved the rubber on the pulley so it will not separate.

In 2008, Mini stopped using the Tritec engine.