The Toyota millimeter-wave radar system consists of several components, including a radar sensor, control module and associated wiring. Mounted typically in the vehicle’s grille or front bumper, the milliwave radar sensor emits high-frequency radio waves and measures the time it takes for them to bounce back after hitting an object. This data enables the radar system to detect and analyze the surroundings, alerting the driver to potential hazards and enabling advanced safety features such as adaptive cruise control, pre-collision systems and lane departure warning.

Calibration is the process of aligning and fine-tuning the millimeter-wave radar system to ensure precise and accurate performance. Calibration is necessary due to several factors affecting the radar’s functionality, such as vehicle modifications, impact events or component replacements. Small changes, like replacing a bumper or adjusting sensor positioning, can disrupt the radar’s alignment, leading to inaccurate readings and potential safety risks.

Vehicle Prep

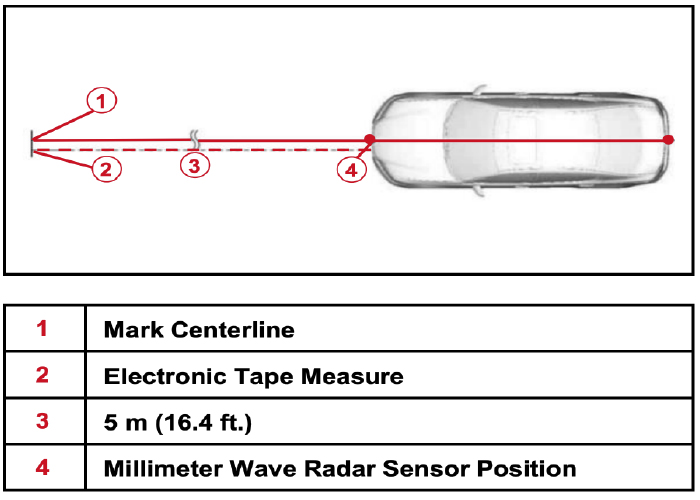

You need to inspect and address basic items before you start the calibration procedure. First, check the tire inflation and set them to the correct pressure. Not doing this can change the angle of the sensor. Second, remove any heavy objects from the vehicle. Third, inspect the battery. If the battery drops below 12 volts, it can cause issues with the calibration.

Level Surface

Never assume a floor is a level. If you see drains or grates in your floor, chances are it has been poured with a very slight angle to let the water drain. If a level surface with a consistent plane is unavailable, use the Floor Slope Compensation Procedure in T-SB-0088-21 in conjunction with the appropriate service information when adjusting the millimeter wave radar sensor. The procedure uses a self-leveling laser that paints a line on the side of the car. The TSB includes a worksheet to calculate the slope of the vehicle relative to the floor. The final calculation will help you to set the inclination of the front radar target.

Clean The Sensor

The milliwave radar unit is typically mounted behind the front badge. There are exceptions for the radar sensor in the Tacoma and Tundra for some model years, these might be positioned behind the grille. Clean the sensor with a towel and ensure no bug guts are in the crevices.

Check For Codes

Before calibrating any ADAS sensor, scan all the modules for codes. The ADAS system and sensors communicate with the instrument cluster, ABS HCU, PCM and even the PCM. If there are any issues with the modules or missing data, the calibration of an ADAS sensor might abort.

Check for Recalls

Some 2018-2019 Tacoma and Tundra models were recalled due to water intrusion of the milliwave radar sensor. The involved vehicles were equipped with a Pre-Collision System (PCS). Due to the mounting of one of the system’s sensors, water can enter the sensor. This can lead to PCS deactivation or inadvertent brake activation resulting in limited deceleration for a short duration of time. The fix was to install a water shield behind the sensor.