Regenerative braking is nothing new – it’s been around just about as long as there have been electric trolley cars and electric trains. And it’s not even a case that it hasn’t been around for a very long time in the auto industry. The difference is that the automotive industry has only recently adopted a large-scale regenerative braking system for itself with the advent of the modern hybrid and electric car.

Regenerative braking takes the forward motion of the vehicle and turns it into electrical energy. This is called “kinetic” energy. The law of energy states: “Energy cannot be created, only transferred.” Thus, in standard friction brake systems that most cars and trucks use today, the energy from applying the brakes is dissipated into thin air as heat.

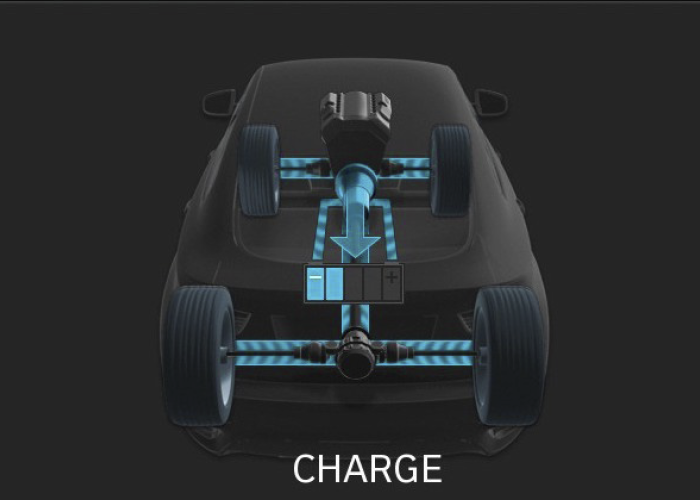

In regenerative brake systems, that same energy is sent to the batteries and stored for later use. This is accomplished through the mechanical connection between the tires and the battery packs by way of the traction motors.

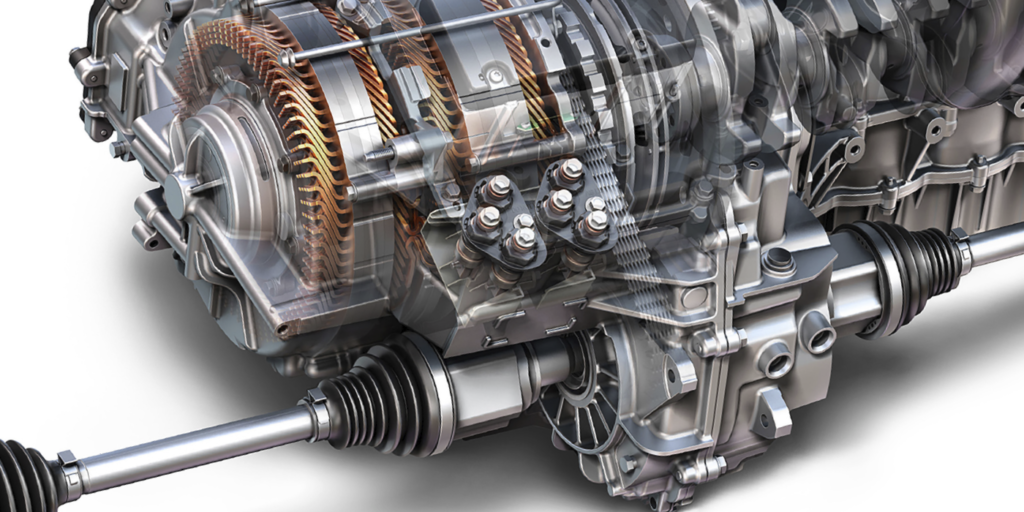

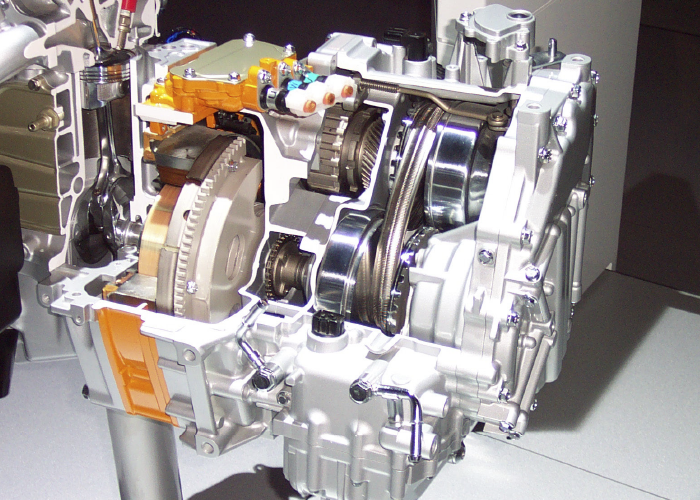

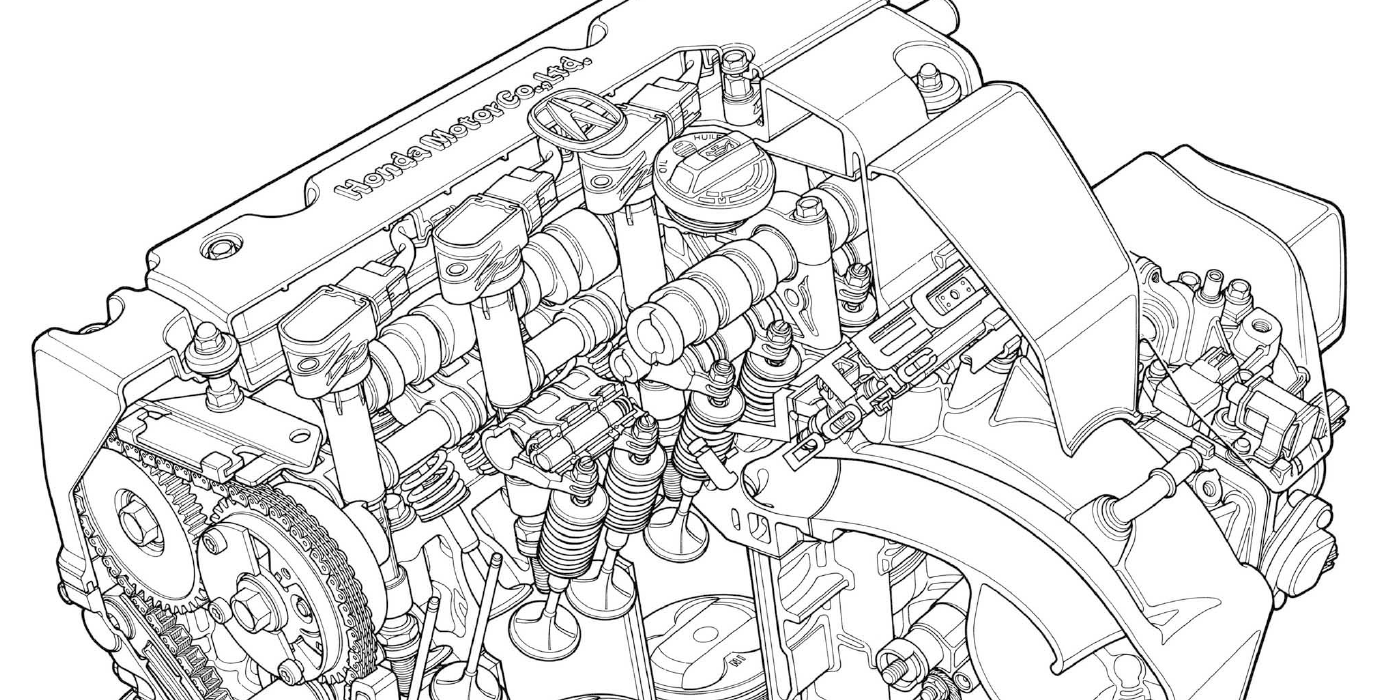

You can visualize regenerative braking as if it were an alternator on a typical mechanical engine. An accessory belt from the engine crankshaft turns the alternator, and as it turns, it produces the required voltage for the electrical systems. In the hybrid systems, its “alternator” (electric motor) is bolted between the engine and transmission (this is the most common setup), or it can be mounted inside the transmission.

With the electronic throttle closed (foot off the gas pedal and/or the brake pedal applied) and the vehicle still moving, the kinetic energy can be captured not only as stored energy for the battery, but as an aid to the friction braking system. This is really noticeable when on a long downhill coast in a vehicle with regenerative braking. You can actually feel the car slowing down under its own electrical power produced by the forward movement of the car.

Regenerative braking systems inherently work better at certain speeds than at others. In fact, they’re most effective in stop-and-go driving situations. Slower speeds and battery usage go hand in hand.

The Toyota Prius, for example, has unique requirements for its brake system. On 2001-’04 models, the hydraulic brakes are not used until the vehicle is below 7 mph unless the vehicle has to make a hard stop. In fact, during many light-braking events, the rear friction brakes will be lightly applied while the front may not be applied at all until the vehicle is at a full or near stop. For this reason, it is normal for a hybrid to wear the rear brake pads two to three times faster than the front pads.

It’s common to see a hybrid with 70,000-100,000 miles on the odometer that still has the original set of front brake pads. This comes back to the earlier point about regenerative braking handling the majority of braking force. This does not mean that other components, like hardware, rubber seals/boots or the brake pads can’t fail for other reasons other than general wear. Weather and time still play a major part in the overall condition of the components. This means that it’s still a good practice to check the brake components during a routine inspection of the vehicle.

Under average driving conditions, the pads may not reach operating temperatures, and corrosion can build up between the backing plate and friction material due to water intrusion and road salt and ice-removal chemicals. This corrosion between the friction material and the backing plate can cause the friction material to separate.

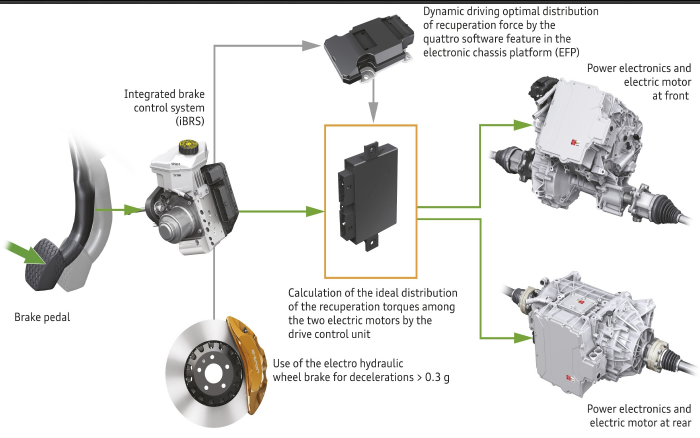

Depending on the request for braking, the system electronically calculates and decides how to apply friction and regenerative braking to meet the demand. Light braking to a panic stop will result in different electronic calculations that various sensors and the ABS controller watch for to direct the appropriate action to be taken. Not only are we seeing a more controlled braking system, but we are also seeing a lot less wear on the friction brake components.

This leads to a lot of drivers who aren’t used to their new regenerative braking thinking there is something wrong. The technician may get a complaint that the brake pedal isn’t always in the same place or that they feel a vibration during certain braking conditions. This is basically normal operation on most regenerative braking systems. The vibration is usually caused by the hydraulic motor for the ABS, and the vibration can be felt through the brake pedal. The pedal grab point is still the same, but the pedal travel can change somewhat depending on the distance and speed traveled before the brake pedal was applied.

Although brake pad wear and brake pad replacement aren’t frequently needed repairs on regenerative braking system vehicles, it’s still a good idea to perform periodic maintenance checks on the entire braking system. The older the vehicle is and the environment in which it operates can have detrimental impacts on the brake system. A few basic checks will keep your customer on the road and make them more at ease knowing their brake system is good to go … well … I mean, good to stop.

Pad & Rotor Replacement on a Prius

It is not uncommon to find a Prius with 70,000-100,000 miles with the original set of pads. This is due to regenerative braking creating the majority of braking force. Remember, though, other components, like hardware and rubber seals/boots, can fail sooner.

The Prius has unique requirements for the brake system. As outlined, earlier, the majority of the time, the pads never reach conventional operating temperatures, and corrosion can only occur between the backing plate and friction material due to the fact that the pads never dry out. On some vehicles, the corrosion between the friction material and backing plate can cause a complete separation.

Always use a high-quality pad for the Prius and other hybrid applications to avoid problems. It is not a question of better performance; it is a question of quality and engineering.

Since it is impossible to perform a conventional break-in/bedding procedure on a test drive, make sure the manufacturer promises excellent performance right out of the box. Also, applying a non-direction finish with a ball hone will help the new pads evenly deposit a layer of friction material to the new rotor.

The Prius uses a two-part shim. The solid piece is the anti-noise layer. The perforated part provides lubrication and acts as a bearing. The two shims’ contact areas float on the lube and slide during application. Always replace the shim and do not reuse an old shim!

There is nothing special about servicing the rotors on this vehicle. But, if you are planning to use an on-the-car brake lathe, make sure the system is off for two minutes. Most on-the-car brake lathes operate below the speed threshold of the generator’s ability to generate voltage.

Rotors that have excessive runout or thickness variation can cause hydraulic pulsations in the brake circuit. These irregularities can cause the pressure sensor to trigger trouble codes C1341 thru C1344, which indicate a hydraulic circuit malfunction.

Hydraulic Components

If you have to replace a caliper, wheel cylinder or brake hose, you must have a scan tool that can clear codes and operate the ABS pump during bleeding. Manual, or “one man” bleeding, will not work on this vehicle due to the valves and solenoids that manage the regenerative braking. Also, the system must be deactivated to prevent damage to the components. Also, read all of the precautions in the service information before attempting to replace any hydraulic component.