“This system in electric and hybrid cars recaptures the energy lost in braking.”

The Jeopardy-type answer is, “What is regenerative braking?” And you’d better understand it, because chances are you’ll be seeing a lot more of it.

The current push for hybrid vehicles and electric cars is about more than just improved mileage. Part of their success is due to the fact that all of them have regenerative braking systems, which are designed to capture something we never worried about before: waste heat.

You probably already know that conventional hydraulic braking in cars and light trucks converts the vehicle’s motion into another form of energy (friction) in order to stop the car. But something like 80% of that converted energy goes out the fenders in the form of heat. Regenerative braking (or regen, for short) is designed to capture that heat and use it, converting it into another form of energy – electricity.

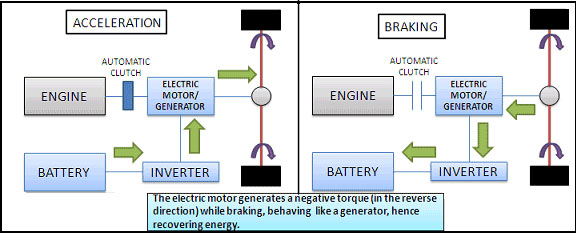

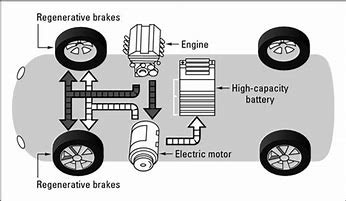

Basics first: regenerative braking can only take place at wheels which are powered by electric motors. In simplified form, in an electric or hybrid vehicle applying the brakes and slowing the car down causes the electric motor(s) driving the wheels to reverse and act as generators, producing electricity. This electricity can do several things – it can go back to the battery to recharge it, it can be used to power electric accessories in the car, or it can be stored for future use. Meanwhile, the electric motor is helping the regular brakes slow the car and in some cases doing all the slow-down work.

Regen does a great job at highway speeds, but it doesn’t work well at low speeds because less stopping energy is being produced, so the regular hydraulic brakes often have to cut in to bring the vehicle to a halt. This leads to the term “one-pedal driving:” when the car is set up so that you can bring it to a halt by just lifting your foot off the accelerator and not hitting the brake pedal at all.

It’s easy to see how all this can help an electric or hybrid vehicle: producing extra electricity can supplement the energy provided by the battery, extending the range of an electric car. Advantages include extended range, more efficient use of the battery, reduced wear and tear on regular hydraulic brake components, lower fuel costs on hybrid vehicles and less air pollution.

Disadvantages include the obviously higher cost of a regenerative brake system, and the impact on the resulting cost-benefit ratio for the complete electrified vehicle.

We tend to think of regen as recently developed high technology. Actually it has a history dating back to the 1890s, when an enterprising operator added regen to his converted-from-horse-drawn electric cabs. Early electric cars like the Baker Electric Runabout and the Owen Magnetic included regenerative braking, but in a complicated and not-too-useful form. The first vehicle that actually employed regenerative braking, i.e., charging the battery as soon as the brake pedal was applied, is said to be the 1967 AMC Armitron experimental electric car. General Motors’ EV-1 was the first commercial application. Regen has been used in railroads for decades as well as auto racing, including Formula 1, since at least 2009.

There are four methods of storing the energy produced by regenerative braking:

- Battery

- Capacitor

- Flywheel

- Hydraulic (we will ignore this for the present discussion)

- The most common method used in passenger cars (but not the only one) is a rechargeable battery. It works well, according to many service professionals. But does it lead to more complicated (and costly) service? Perhaps not. Greg Hunt, a service technician with Brian Hoskins Ford, Coatesville, PA, has worked extensively with electric cars.

“Electric cars are great – they’ve got tons of power, they’re great in the snow. But the great thing is the deceleration the regenerative braking can provide. It boosts your range and really extends the life of the regular brake parts. If a car normally needs a brake job at 30-40,000 miles, you might get 50-100,000 miles on the same car with regeneration,” says Hunt.

“We rarely see problems with the regen systems. We mostly see the hydraulic brake components starting to fail due to age and lack of use,” he explains.

Regenerative braking is common in all hybrid cars, and in electric cars built by manufacturers like Nissan, BMW, Volkswagen, Audi, Hyundai, Chevrolet and Tesla. Some cars offer drivers the option of selecting how much regenerative braking to use in a particular situation: for example the Hyundai Kona Electric has four settings, ranging from 0, representing “coasting” without brakes, to 3, for maximum brake force using both regen and hydraulic brakes.

Is regenerative braking a growing thing? The answer seems to be, “You ain’t seen nothing yet.” One study by India-based Prescient & Strategic (P&S) Intelligence pegged the global regenerative brake market in 2017 at $6.555 billion. Several other companies including BIS Research Inc., Fremont, CA projected the market to be $24.52 billion by 2026; BIS says that would represent something over 16 million units.

A study by Robert Bosch LLC, Farmington Hills, MI, of 1,000 recent car buyers who plan to buy another car within 5 years revealed that 62% believe they will own an all-electric vehicle in 10 years or less, and 71% of those believe all their vehicles will be electric within 15 years. Fully 62% said they would be willing to buy an all-electric vehicle at an additional cost of $10,000 (after tax credits) versus the same vehicle with a gas engine.

So Joe Technician is going to see more and more regenerative braking systems in the next few years. Just how many depends partly on how far electric cars advance. Electric vehicles are expensive, even with federal and state rebates, and no one knows how widely recharging stations will spread across the country.

Joe is also going to see some variations on the standard regen setup, too. Manufacturers are pursuing their own lines of research on what to put out in the field. Here are just a few examples:

- Jaguar’s i-PACE SUV features an “enhanced regenerative brake system” that claims to recover almost all of the energy created in braking.

- Porsche’s Taycan EV Turbo S model (0-60 mph in 2.8 seconds) has three regen settings and seamlessly blends regen braking with mechanical; it uses massive 16.5” discs in front and calipers with 10 pistons for the mechanical side.

- Mazda is producing Miatas bound for Europe that use regenerative braking in a non-electric car. Mazda says it uses a variable voltage alternator with a low-resistance, high capacity capacitor; it calls the system i-ELOOP.

- Continental AG is developing what it calls a “New Wheel Concept,” a design that permits greater use of aluminum in the regenerative brake system which means less weight overall and therefore even less reliance on regular friction braking.

We can count on plenty more developments from key suppliers to the automotive aftermarket. And a well-trained, regen-familiar Joe Technician can count on lots of job security.