This month, we’re going to look at the Subaru line of cars and some of the engine problems you may encounter. Here in the northeast, Subarus are very popular — they are hard to beat if you’re looking for a good, solid 4WD car.

Subaru has always used a boxer-style engine with opposing cylinders. By going this route, it is able to keep the crankshaft in line with the driveline, and it also has a compact design for good packaging. If there is one downside to the Subaru engine, it would be its tendency to leak oil and coolant from the head gaskets. The cars built in the early 2000s also had issues with leaks coming from the timing belt covers. When we first encountered this problem, it caused some comeback issues until we found out the real culprit was the screws on the rear plate of the oil pump. The comebacks stopped once checking and tightening the bolts became part of our routine procedure whenever the timing belt was replaced.

Speaking of timing belts, the most common engine job you’ll be doing on these vehicles is timing belt replacement. While you can review the nuts and bolts of the timing belt job using your service information system, I’d like to share some of the things we do to ensure a smooth and trouble-free job.

The most important thing is to have the associated parts on hand or readily available should you need them. Those items include the crankshaft and camshaft seals, the hydraulic tensioner and pulley, as well as the idler pulleys.

The majority of the Subarus we have towed in with timing belt failure can often have the issue be traced to an idler pulley failure that resulted in the belt coming off. Replace the pulleys if you have any doubt about their condition, notice grease coming out of them, or if there is roughness or noise when they are spun. The same replacement suggestion applies with the hydraulic tensioner if there is any sign of leakage, or if it’s not moving smoothly as you press the piston in to install the lock pin. With any timing belt job, replacement of the water pump and drive belts are a given on higher mileage cars, and a thermostat replacement is also recommended.

One other tip I recommend is using the starter to loosen the crankshaft bolt. Position a breaker bar under the left-side frame member and hit the starter; the torque of the starter will quickly loosen the bolt.

Keep in mind that Subaru doesn’t set the timing belt at TDC. Instead, it uses timing marks that position the camshafts so the pressure of the valve springs won’t turn the cams and the pistons are out the way while installing the belt.

While we are talking about timing belts, try to use a brand that has the timing marks on the outside of the belts. It’s much easier than trying to line up the marks without having a straightforward look at them.

If the timing belt should break or the car has an idler bearing failure, the valves may contact the piston. It’s been our experience that while the automatic transmission cars are less likely to have this problem, it can still occur. Our standard procedure is to get approval for the timing belt job. The first step is installing the belt to be sure all is well. It takes only minutes and will prevent you from having a car that needs a new water pump, coolant and thermostat, only to find out the customer wasn’t prepared for a big job.

Timing Belt Replacement

There will be times when you run into some unusual problems. We recently got a call from the body shop with which we work. While it is a top-notch body shop that does exceptional work, they don’t always hit the mark when it comes to mechanical issues even though they put their best efforts forward.

A few months ago, the body shop called looking for a Subaru cylinder head. They had a Legacy wagon in the shop that was hit hard enough in the left front that contact was made with the timing belt cover and cam gear. Fearing that the camshaft and head were damaged, they thought it was best to replace the head. As luck would have it, we had a core engine that was low on oil and developed a rod knock. Since the engine was out for the body repair, they replaced the cylinder head with the one we gave them. With the car repaired, it was sold to one of their customers for the daughter to use. All was going well for about 400 miles, until the car broke down on the road and was towed to our shop.

It didn’t take long for us to determine that the timing belt had apparently failed. All it took was turning the key to the start position to hear that distinctive freewheeling sound of an engine with no compression. Knowing that the belt was recently replaced, we suspected a tensioner or idler pulley failure.

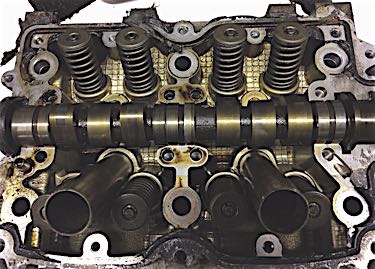

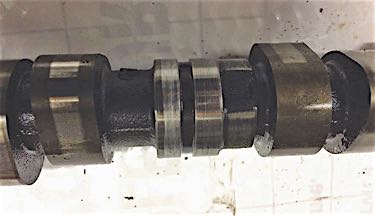

With the car in the shop and the timing belt covers removed, we were a bit surprised to find the timing belt was broken and there was damage to the teeth. As mentioned, our first step is to install the belt and confirm the engine runs on all the cylinders. In this case, we couldn’t do that since the left-side camshaft was seized in the head. This surprised us since we checked the head when they got it. Everything looked good and there was no apparent damage from the engine running low on oil.

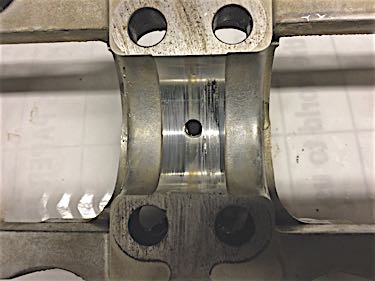

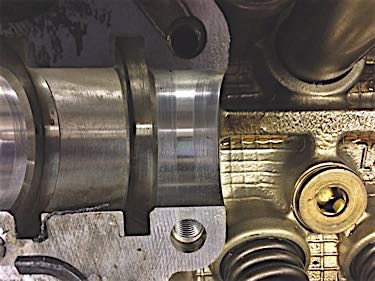

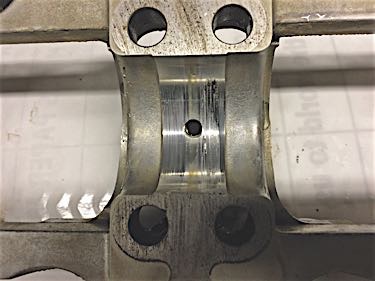

When talking to the guys at the body shop, it didn’t take long for us to realize where they went wrong. When they removed the valve cover, even though it didn’t look like there was any damage, they replaced the camshaft just to be on the safe side. But, unfortunately, they also replaced the upper cam bearing cradle using the one from the replacement head. Since the job was performed by a friend who was a subcontractor, no one was sure if it was done by design or in error, but at this point it didn’t matter. The mismatch on the bearings resulted in tight clearances seizing the cam in the head, and the engine would now need another head.

When you first open the hood to replace a head or gasket on a Subaru, it can be a little intimidating, as the packaging is tight and boxer design has the cylinder heads located close to the frame. But the job isn’t nearly as bad as it looks. We’ll walk you through the job sharing some of things we do along the way. As mentioned earlier, external oil and coolant leaks are fairly common, and we have done our share of fixing them. We’re looking at a 2.5L single-cam four cylinder engine; the procedure will change for the less common twin-cam or the six cylinders. You’ll be removing the engine with those configurations.

Things open up as the air intake system, battery and other accessories are removed. If it’s a high-mileage car, you might want to take advantage of the access afforded and replace the spin-on trans filter located behind the battery. There is no need to remove wiring on the intake manifold since it will remain in place. Next, remove the hardware mounting the manifold and block it up to clear the studs at the head. Under the car, remove the exhaust system, lowering the motor mount nuts on one side and loosening the other.

While lowering the car, we place a jack stand under the motor mount bracket on one side and slowly lower the car, which raises one side to provide access to the valve cover and cylinder head. Note: Be careful not to raise it up too high, as you risk pulling the inner CV joint out of the transaxle. If you’re in doubt, it’s easy to check when the car is raised, but you have to remember to look.

Typically when we are replacing the head gaskets, the heads almost always show more than 0.003-in. variance and need to be resurfaced. If the engine was running well and the valves and seats look good, we have had good results with resurfacing versus having the valves reconditioned. Of course, the heads get a thorough cleaning before being installed.

I didn’t talk about the diagnostic process since the majority of gasket replacements you’ll be seeing are to correct an external oil or coolant leak that doesn’t require a great deal of diagnosing. But care should be taken to ensure that the leak is actually at the head gasket. It’s a pretty simple check: Clean the area and drive the car, and a quick inspection will confirm the source of the leak.

I hope this article will give you some confidence if you find yourself looking at a Subaru with a leak. Just remember to always use quality parts whether it be for a timing belt job or replacing the head gaskets, and you will never have to do the job twice on the same vehicle.