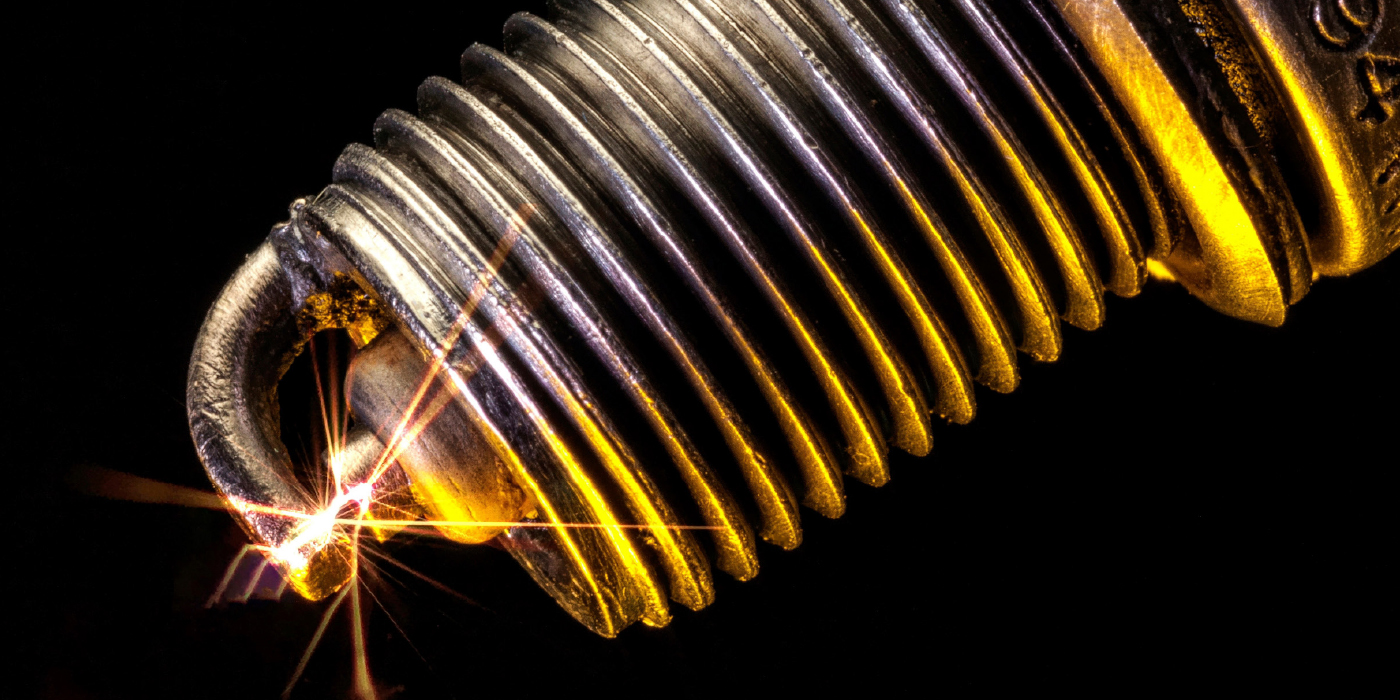

In the days of the in-line, four-cylinder Datsun B210 and the air-cooled, flat-four Volkswagen sedan, changing spark plugs was “no big deal.” But times have changed because, since 1996, import manufacturers began installing long-life spark plugs to prevent spark plug misfires from ruining expensive catalytic converters covered under the EPA-mandated eight-year, 80,000-mile emissions warranty.

The complexity of replacing spark plugs began when we found ourselves spending several hours removing an upper intake plenum on a transversely mounted engine to replace three long-life spark plugs located on the rear cylinder bank. Worse still, replacing the spark plugs became even more complex when we discovered that a careless installation could cause the new spark plug to misfire and the dreaded bright-orange Malfunction Indicator Light (MIL) to come on. So, yes, in today’s market, replacing spark plugs is a “big deal” indeed.

Replacement Spark Plugs

At the outset, I’ll say that the safest choice of replacement spark plug is an OE-approved brand and part number. On the other hand, because it’s nearly impossible for most suppliers to stock all brands of spark plugs in all heat ranges and configurations, most of us are occasionally faced with choosing a substitute brand for a particular import application. Using one’s experience in choosing an alternate brand is perhaps the next safest method of selecting a replacement spark plug.

What no responsible technician should do is choose a steel-shell spark plug with non-plated threads to replace a more expensive plated-shell spark plug with rolled threads. Although spark plugs with non-plated threads are relatively rare in today’s market, it’s important to know that steel spark plug threads easily seize to aluminum and are very likely to ruin an aluminum cylinder head.

Choosing the correct spark plug configuration is also important. Cases in point are Toyota applications that require dual-ground electrode spark plugs. If a single ground electrode spark plug is installed, the engine will likely develop the familiar P0300 misfire trouble code and turn on the MIL.

Similarly, there’s absolutely no reason to change the spark plug heat range in an OBD I or OBD II engine. Most spark plugs in computer-controlled engines are designed to run near the edge of preignition. Installing one range hotter can tip the balance in favor of preignition and its closely related companion, detonation. Preignition tends to melt the center out of pistons, whereas detonation or “spark knock” can chip or break the insulator tips on spark plugs or, at the worst, break piston rings and piston skirts.

Installing colder heat ranges for rally and other performance contests is allowable, providing that the installer understands that the spark plug may foul under normal operating conditions and cause an ignition misfire. In these cases, the installer should be aware that short spark plug life is but one of the consequences of a colder spark plug heat range.

Spark Plug Tooling

Tooling has changed from the old 13/16-inch spark plug socket to a multiplicity of 5/8-inch long, short, intermediate and swivel, thin-wall sockets needed to replace spark plugs on modern import engines. Similarly, tightening spark plugs with the old flex-head, long-handled, 3/8-inch drive spark plug wrench is asking for trouble on engines that don’t have long-reach spark plug threads in the cylinder head.

Tooling has changed from the old 13/16-inch spark plug socket to a multiplicity of 5/8-inch long, short, intermediate and swivel, thin-wall sockets needed to replace spark plugs on modern import engines. Similarly, tightening spark plugs with the old flex-head, long-handled, 3/8-inch drive spark plug wrench is asking for trouble on engines that don’t have long-reach spark plug threads in the cylinder head.

Consequently, the compact inch-pound torque wrench is a necessary tool for correctly torquing spark plugs into modern aluminum cylinder heads. See Photo 1.

Modern spark plugs are generally torqued between eight and 17 foot-pounds of torque. To illustrate the degree of these values, eight foot-pounds can easily be achieved using a short quarter-inch drive ratchet. Seventeen foot pounds can be easily achieved using a short 3/8-inch drive ratchet.