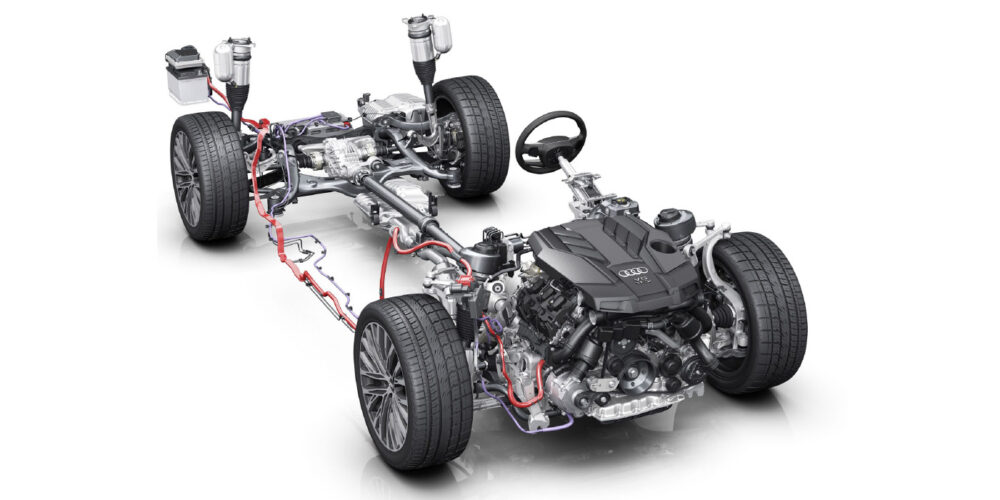

Here is a tech tip you can use if you are seeing more hybrids and stop/start vehicles with noise complaints at your shop. Noise problems can be challenging to replicate on these vehicles because the gasoline engine doesn’t run constantly and starts only under specific conditions.

With hybrids, the customer might complain a noise occurs when another action is taken, like moving his or her foot off the brake pedal, changing the settings of the HVAC system or if extra power is required for acceleration.

The symptoms the customer may describe might seem like the problem is intermittent or random. But when the engine starts and stops, it is regulated by the engine management system.

So, how do you force a hybrid vehicle to start? For some vehicles, just put the vehicle into park and tap the accelerator, or switch the gear shifter to the manual or sport position. For some, selecting an HVAC setting that is hotter or colder can cause the engine to restart. For other vehicles, it could be more complex, and you might even need a scan tool. The information for the procedure is typically in the service information. Also, check the TSB and other bulletins for the procedures for a force start and the conditions for stopping and starting the engine.

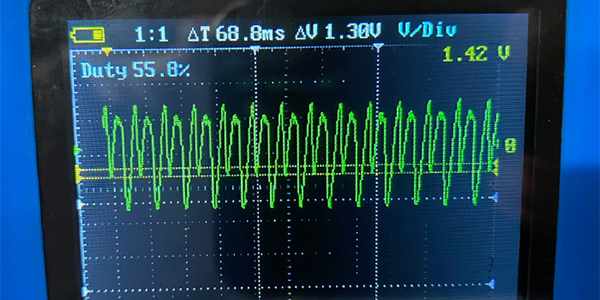

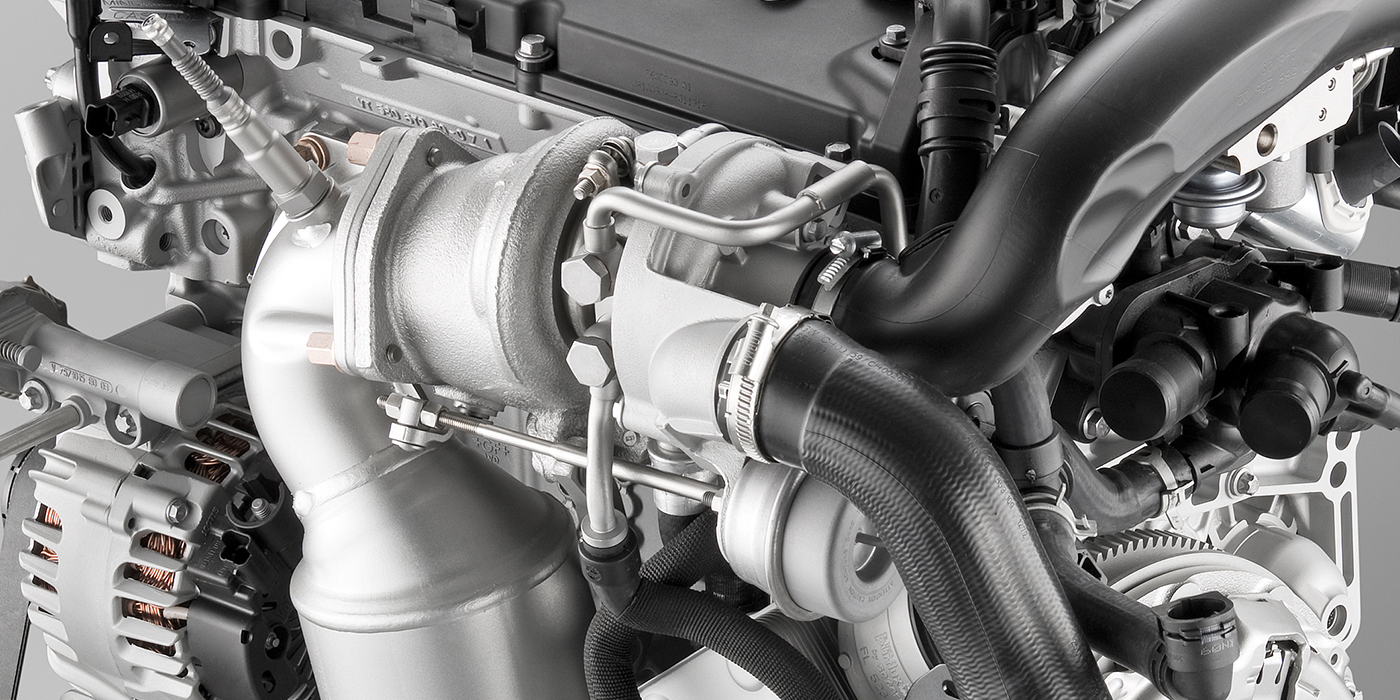

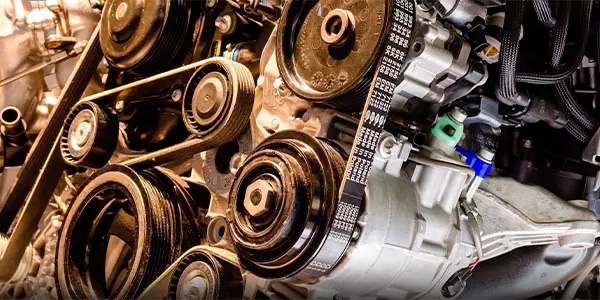

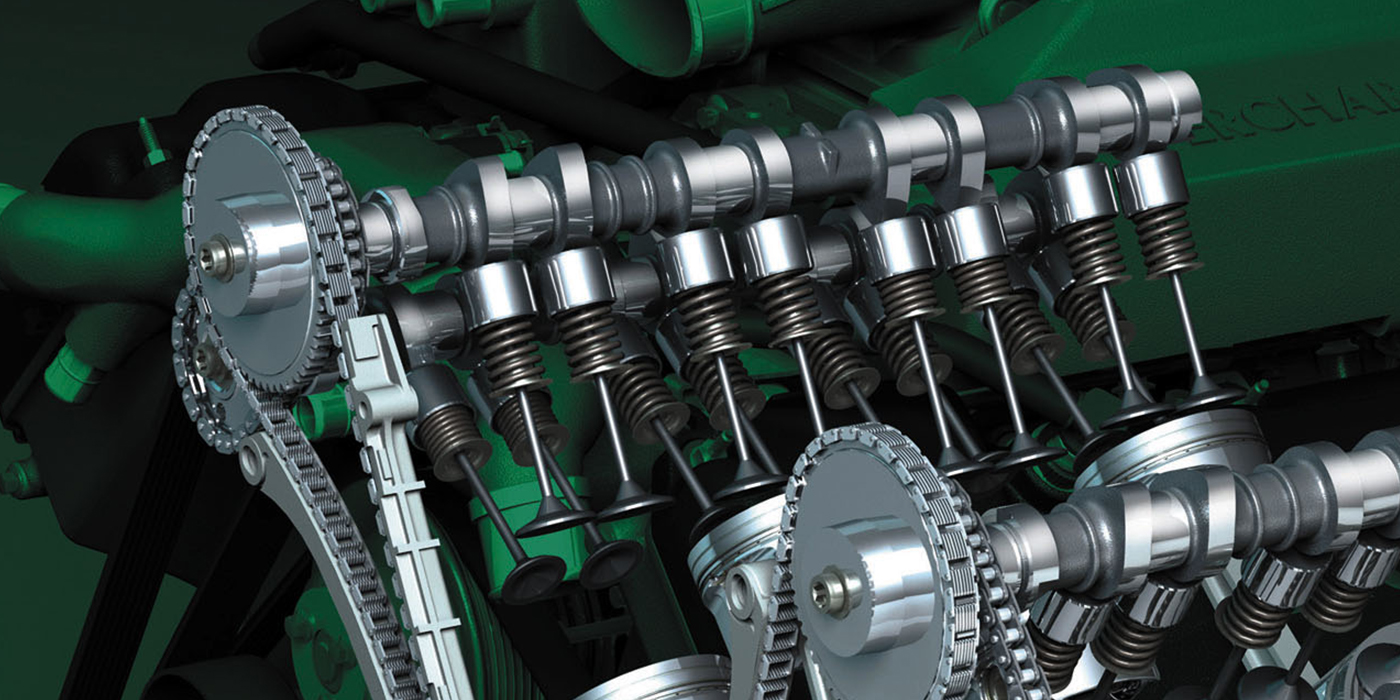

Knowing how to “force start” a hybrid vehicle can be helpful if you are trying to diagnose a noise problem that involves the accessory belt drive system. Just like a conventionally powered ICE vehicle, most belt noises occur when the engine is started and first running. Low engine speeds are when belt flutter can occur because the belt needs to get the components on the belt drive system spinning. This is when the tensioner is working its hardest to keep tension on the belt.

The noise complaint from the customer might say it is a squeaking noise. Also, they might say they are hearing a tapping noise. The belt squeaking noise is caused by the belt slipping due to a lack of tension, which is almost always due to a worn or damaged tensioner. The knocking or tapping noise is caused by the tensioner moving rapidly back and forth, trying to fight the flutter.

Tensioners for hybrid vehicles are designed with the lowest possible belt tension, reducing energy losses and improving system NVH.

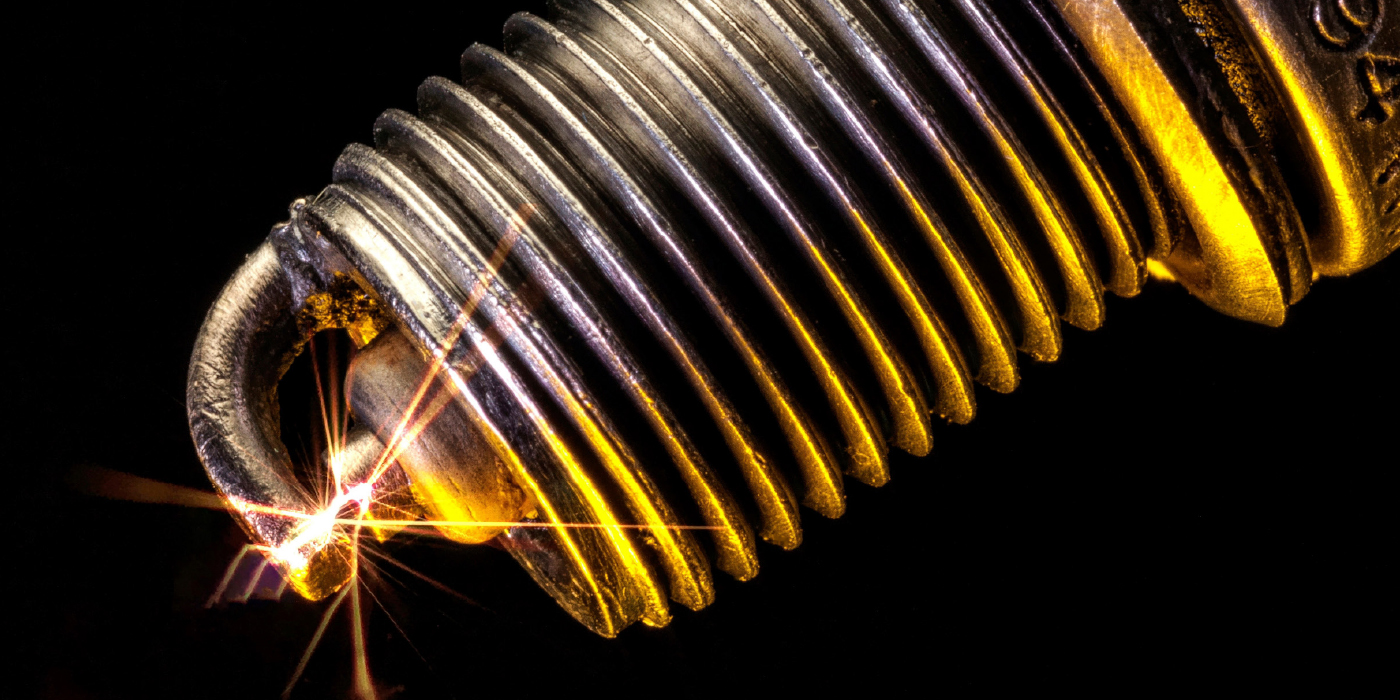

Another component that can cause noise on hybrid and stop/start equipped vehicles is the decoupler pulley or overrunning decoupler pulley, or OAD. When a decoupler fails, it can cause noise when the engine is turned off. Listen for any noises from the OAD after the engine is shut off. A worn-out bearing will generate a “buzz” noise during this test. If the OAD is noisy, replace it.

No matter the noise or vehicle type, take the time to interview the customer and collect all of the information about the noise and when it occurs. Also, never take a chance on parts when it comes to serving these vehicles. The belt tensioner on these vehicles is engineered to exacting tolerances to achieve the quietest performance with the least amount of tension possible. Using a low-quality tensioner and belt could cause a very expensive comeback.