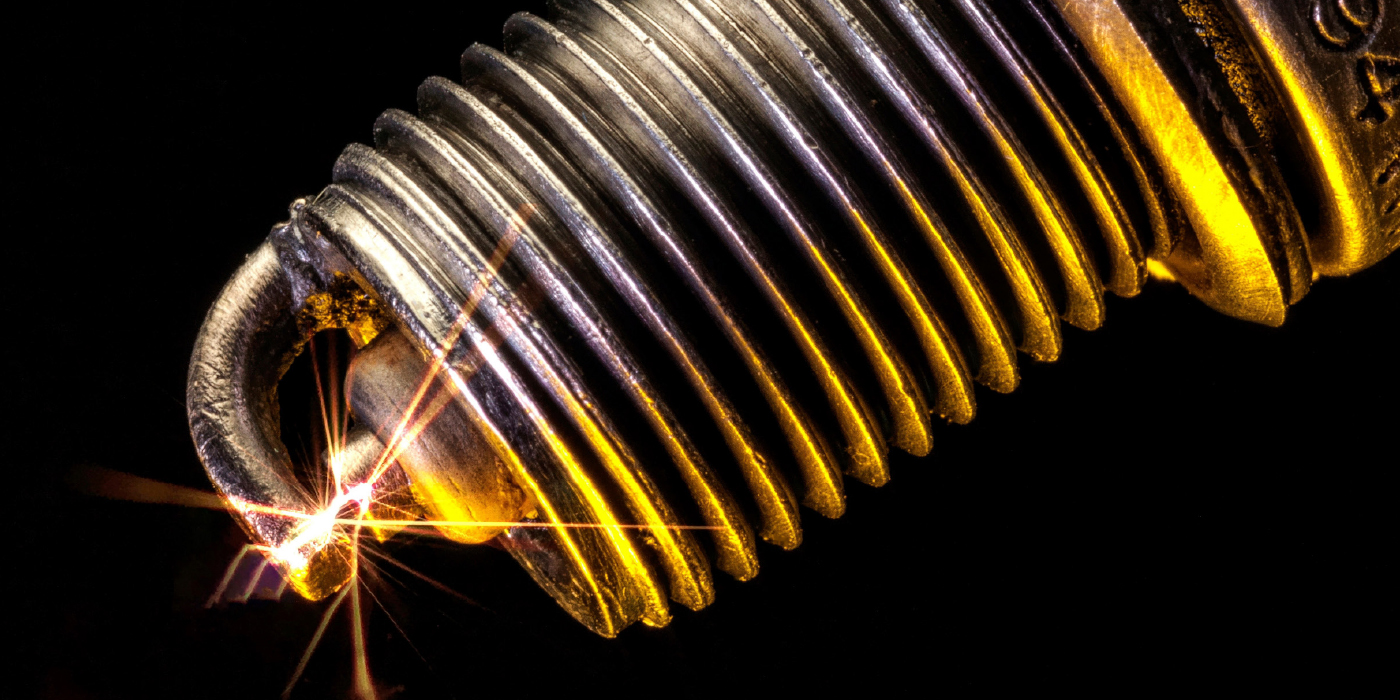

If the spark plug is over-torqued into an aluminum head, the aluminum threads begin to “roll over,” causing a high degree of friction when the spark plugs are removed. In worst-case scenarios, the threads actually separate or strip from the cylinder head casting and may require removal of the cylinder head to repair. In other cases, over-torquing a spark plug can distort and break the seal between the metal shell and porcelain insulator, which causes combustion gases to leak into the spark plug boot and blow it off the spark plug. If a spark plug boot keeps blowing off, suspect a seal leak caused by an over-torqued spark plug. See Photo 2.

If the spark plug is over-torqued into an aluminum head, the aluminum threads begin to “roll over,” causing a high degree of friction when the spark plugs are removed. In worst-case scenarios, the threads actually separate or strip from the cylinder head casting and may require removal of the cylinder head to repair. In other cases, over-torquing a spark plug can distort and break the seal between the metal shell and porcelain insulator, which causes combustion gases to leak into the spark plug boot and blow it off the spark plug. If a spark plug boot keeps blowing off, suspect a seal leak caused by an over-torqued spark plug. See Photo 2.

If the spark plug is under-torqued, combustion gases begin to leak past the tapered seat or metal gasket. This leakage causes carbon to form around the threads that, in turn, causes the spark plug to seize to the cylinder head. A properly torqued spark plug will show a bright register mark on the tapered seat or the gasket will show compression. See Photo 3.

If the spark plug is under-torqued, combustion gases begin to leak past the tapered seat or metal gasket. This leakage causes carbon to form around the threads that, in turn, causes the spark plug to seize to the cylinder head. A properly torqued spark plug will show a bright register mark on the tapered seat or the gasket will show compression. See Photo 3.

All of the above are good reasons to take a little extra time to properly torque the new spark plug.

Spark Plug Removal & Installation

Although it doesn’t seem to be critical on all engines, it’s always advisable to let an engine with an aluminum cylinder head cool down to help expedite safely removing the spark plugs. Next, it’s extremely important to use compressed air to blow dirt and other debris away from the spark plug. If dirt remains after the spark plug has been removed, insert a long air nozzle into the cylinder itself to blow the remaining dirt out of the spark plug threads.

Many manufacturers recommend soaking the spark plug threads with suitable penetrating oil before removal. In some cases, it’s advisable to back the spark plug out about 1/4 turn to allow the penetrant to soak into the threads. If, after the penetrant has been allowed to soak and the spark plug still feels seized into the cylinder head, continue to remove the spark plug from the head by adding penetrant and alternately tightening and loosening the plug to lubricate the spark plug threads.

If the spark plug threads appear damaged or caked with carbon, use one of many spark plug thread chasers now on the market to clean the threads. See Photo 4.

If the spark plug threads appear damaged or caked with carbon, use one of many spark plug thread chasers now on the market to clean the threads. See Photo 4.

If the threads are stripped, a number of aftermarket tool companies offer repair kits that allow the threads to be replaced in chassis.

Remember that secondary ignition voltage has increased from about 20-25,000 volts on contact point ignitions to about 60,000 volts on modern distributorless or coil-on plug ignition systems. Spark plug installation in a modern engine requires care and cleanliness to contain these high firing voltages. A greasy fingerprint on the exterior insulator can, for example, rapidly develop into a misfire-causing carbon track or flash-over. If a spark plug shows evidence of flash-over, the spark plug boot or wire contains a companion trace and should also be replaced to prevent a comeback.

To avoid leaving fingerprints on spark plugs, remove the spark plug from its box by grasping the metal shell. Next, insert the spark plug into a recently cleaned rubber hose, spark plug boot or spark plug socket to allow for checking the air gap and other service operations. See Photo 5.

To avoid leaving fingerprints on spark plugs, remove the spark plug from its box by grasping the metal shell. Next, insert the spark plug into a recently cleaned rubber hose, spark plug boot or spark plug socket to allow for checking the air gap and other service operations. See Photo 5.

If it appears advisable to apply some anti-seize compound to the spark plug threads, prevent contaminating the center electrode by using a small tinning brush to dab a small amount of compound to the ground electrode side of the threads. Use anti-seize compound sparingly because a misfire can develop if anti-seize spatters onto the spark plug’s center insulator.

Next, use an inch-pound torque wrench to tighten the spark plug to specifications. Remember that multiplying a foot-pound torque specification by 12 will make the conversion to inch-pounds on the torque wrench. If you’re using anti-seize compound on the spark plug threads, use the lowest specified torque value. Last, use a small, round brush to apply a coating of dielectric grease to the inside of the spark plug boot to seal the boot against moisture and expedite future removal.