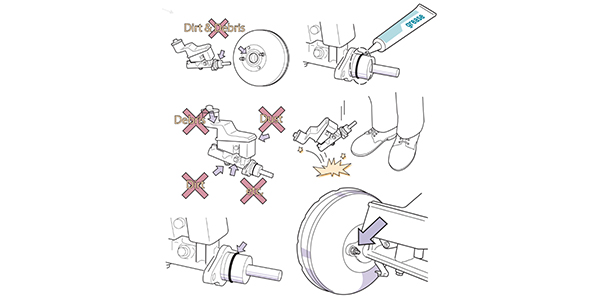

1. Ensure that mounting areas of the master cylinder and the pipe joints are free of damage and debris. Fluid leakage and improper hydraulic pressure may cause brake failure.

2. Do not allow dust, dirt and debris to enter the master cylinder or reservoir tank. Internal damage may occur, resulting in fluid leakage and improper hydraulic pressure.

3. Always use a new O-ring or gasket if required for installation. Ensure proper installation of the O-ring or gasket for proper sealing. Fluid leakage and improper hydraulic pressure may cause brake failure.

4. Use grease on O-rings and gaskets before installation for proper sealing and installation. Grease will help seal and install the brake master cylinder correctly to ensure proper hydraulic pressure.

5. Handle with care. Brake master cylinders are precision manufactured. Do not drop or deform. Never use a damaged unit.

6. Tighten bolts, nuts, and screws and utilize the proper tools as specified by the service information. Damage of screws and threads may cause improper braking function.

7. Use new brake fluid that is specified by the manufacturer’s service information. Bleed the air accordingly to release trapped air within the hydraulic system.