Gasoline direct injection (GDI) may be one of the biggest automotive advancements from the past few decades, and has become all but standard in the internal combustion engines of today. GDI systems inject fuel at incredibly high pressures directly into the combustion chamber. The high pressure allows for better atomization of the fuel inside the cylinders, and much more precise control over the volume of fuel being injected.

Mercedes-Benz has long been a pioneer of GDI. It first experimented with the technology in its iconic 300 SL in 1954. The problem then was that it was too far ahead of its time, as carburetors were cheaper and easier to produce. In 2002, M-B released a new 1.8-litre four-cylinder engine with a new generation of direct injection. Just four years later, it released the direct injection V6 engine in the 2006 CLS 350 GDI. This engine was the first gasoline engine in the world to use piezoelectric injectors, and it boasted 10-15% better fuel economy and increased horsepower and torque over the previous generation of engine.

The M276 and M278 Engine Family

The M276 V6 and M278 V8 engines were installed in a number of Mercedes-Benz models from 2011 up to around 2020. The M276 is a naturally aspirated V6, and the M278 is a bi-turbo V8. Both engines have proven to be pretty reliable, but they are, of course, not without some faults, including the high-pressure fuel pumps (HPFPs).

They have been replaced in recent years by a newer generation of engines known as the M176, M177, and M178 engines. How do you tell the difference? That’s easy. The M276 and M278 are standard configuration engines, so you’ll find the intake manifold inside the “V” of the engine, and the exhaust manifolds will be on the outside (closer to the strut towers.) If you see the exhaust manifolds inside the V, you’re looking at the M176/M177/M178 family of engines.

The High-Pressure Fuel Pump (HPFP)

There are a number of components in the fuel system, all of which need to work together for the system to perform at its best. We’re going to focus on the HPFP and how it operates.

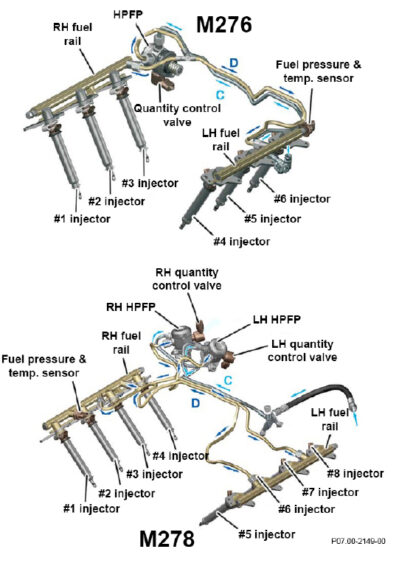

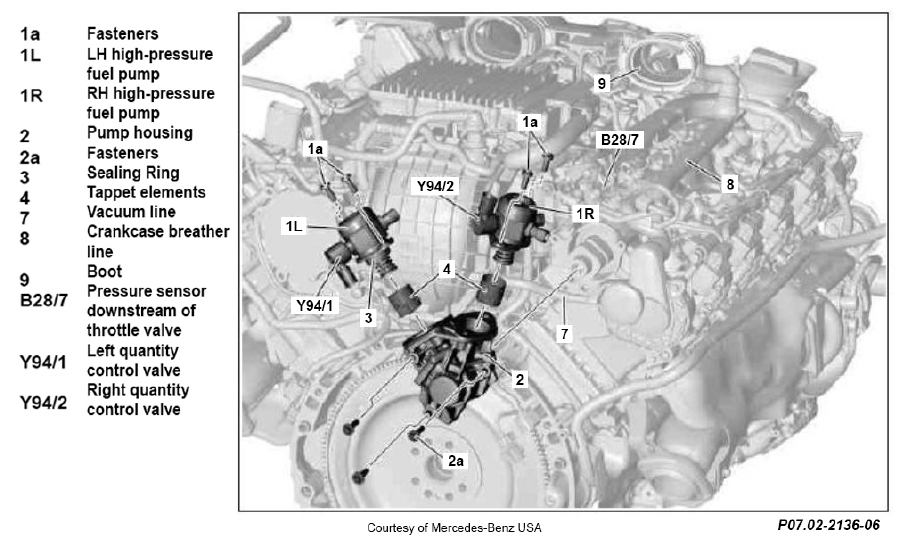

These engines use a non-return GDI system with two separate fuel rails, one for each bank of cylinders (Figure 1). The in-tank fuel pump supplies low-pressure fuel to the HPFP. The M276 engine uses a single HPFP, while the M278 uses two. They are located on the back of the RH cylinder head on both engines, and are driven by the intake camshaft. The M276 HPFP is driven by a three-sided cam lobe, and each of the M278 HPFPs are driven by a shared four-sided cam lobe.

Each time the cam lobe actuates HPFP, the internal piston pressurizes the fuel to between 120 and 200 bar. This high pressure is then regulated and stored in the fuel rails. Fuel can be injected by the piezoelectric fuel injectors up to five times per cycle depending on the needs of the engine.

A control valve is mounted on the side of the HPFP. The ME-SFI control unit uses this valve to control how much fuel is being sent to the fuel rails. Fuel pressure and temperature are monitored via a combination sensor which will be mounted onto one of the fuel rails.

Tips & Tricks

Now let’s look at what you should expect if you need to replace the HPFP on one of these engines.

First of all, there’s very little room to work around the HPFP. This means that you may need to get creative when it comes to working efficiently, and to keep from dropping tools or parts into the engine bay. I would suggest keeping a set of magnetic sockets and/or extensions on hand, as well as an assortment of telescoping grabber tools, inspection mirrors, and whatever other tools you typically grab for “tight quarters” repairs.

Customers may complain of high-frequency ticking or pulsing noises coming from the high pressure pump and/or the fuel injectors. These systems can be noisy; it’s been a common complaint with other manufacturers, as well. That being said, trust your gut and the diagnostic process. Compare the noise in similar conditions – with and without the foam sound insulation over the HPFP, with the engine hood open and closed, and from inside and outside of the vehicle cabin. If you think that something doesn’t sound right, perform a visual inspection.

If there is a heat shield or cover on top of the HPFP, crack all of the bolts loose before fully removing any of them. You may find that the shield wants to rotate when you go to crack the final bolt loose, so it’s better to leave them all in to prevent this from happening.

It’s extremely important that you clean the area around the HPFP before removing it. Brake cleaner, compressed air, whatever is needed to prevent dirt, debris and other contaminants from falling in once the HPFP is removed. If the HPFP is going to be removed for a prolonged period, cover up or plug the hole. Masking tape would be fine, but there are plenty of alternatives. The goal is to prevent debris or contaminants from falling in.

When installing the new pump, you may find it easier to plug in the electrical connector before seating the pump into place. Again, space is at a premium around the HPFP. But, once it comes time to reconnect the fuel lines, you should always thread the fittings on by hand before tightening them down. Reference the OEM service information for the torque specifications on these fittings; we’re not talking about a lot. If you over-tighten them and shear the threads off, it could be a really expensive mistake!

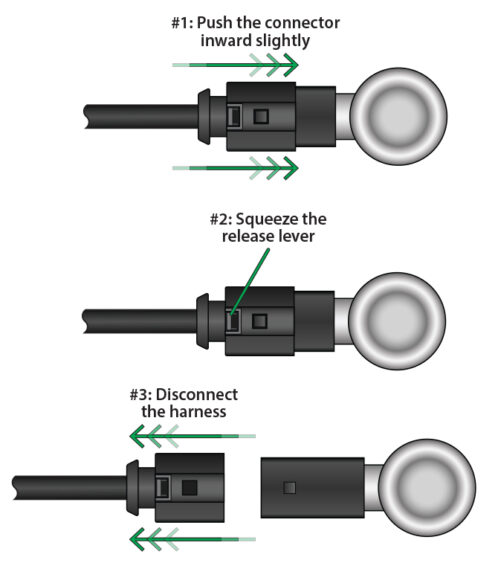

One final tip, something that many specialists will already know about, but not everyone: The electrical connector on the HPFP is a “push then pull” type of connector. This means that you need to push the connector slightly toward the device, then release the locking tab and pull the connector off of the plug (Figure 2). Pushing the connector inward will help to relieve the tension from the locking tab, which should reduce the likelihood of it breaking off on you.