Late-model vehicle technology is changing. Wider tires, active safety systems and AWD technology are not only influencing how vehicles perform, but also the service and maintenance requirements of their functional fluids.

POWER STEERING FLUID

OE Interval: 60,000-100,000 miles

What has changed? Wider wheel and tire packages are putting more strain on power steering systems. More strain on the pump and rack means more heat. This heat can degrade the power steering fluid and eventually damage the seals and internal surfaces of the pump and rack.

Customers need to be aware there is no such thing as universal power steering fluid, as many models use specific formulations that are compatible with the seals in the system. A low fluid level is a sign that there is a leak. But, topping off with what is available at the gas station can do more harm than good, in some cases.

Some new power steering fluids on the market are designed to reduce the pump’s drag on the engine. If the wrong fluid is installed, it could damage the pump and the rack.

BRAKE FLUID

OE Interval: Based on the age of the fluid.

What has changed? ABS, ESC and traction control have become standard on most vehicles sold during the past decade. When the system activates to either release or lock a wheel, the hydraulic control unit’s valves can be hard on the brake fluid. The high pressure and force exerted on the fluid can degrade the fluid and also degrade the additive package and base stock.

The brake fluid is designed to have a specific viscosity, so when a valve opens the brake fluid flows as expected. But, water contamination and changes to the additive package can change the viscosity. In some cases, worn out brake fluid can cavitate and cause air bubbles in the fluid when it’s forced through the valves.

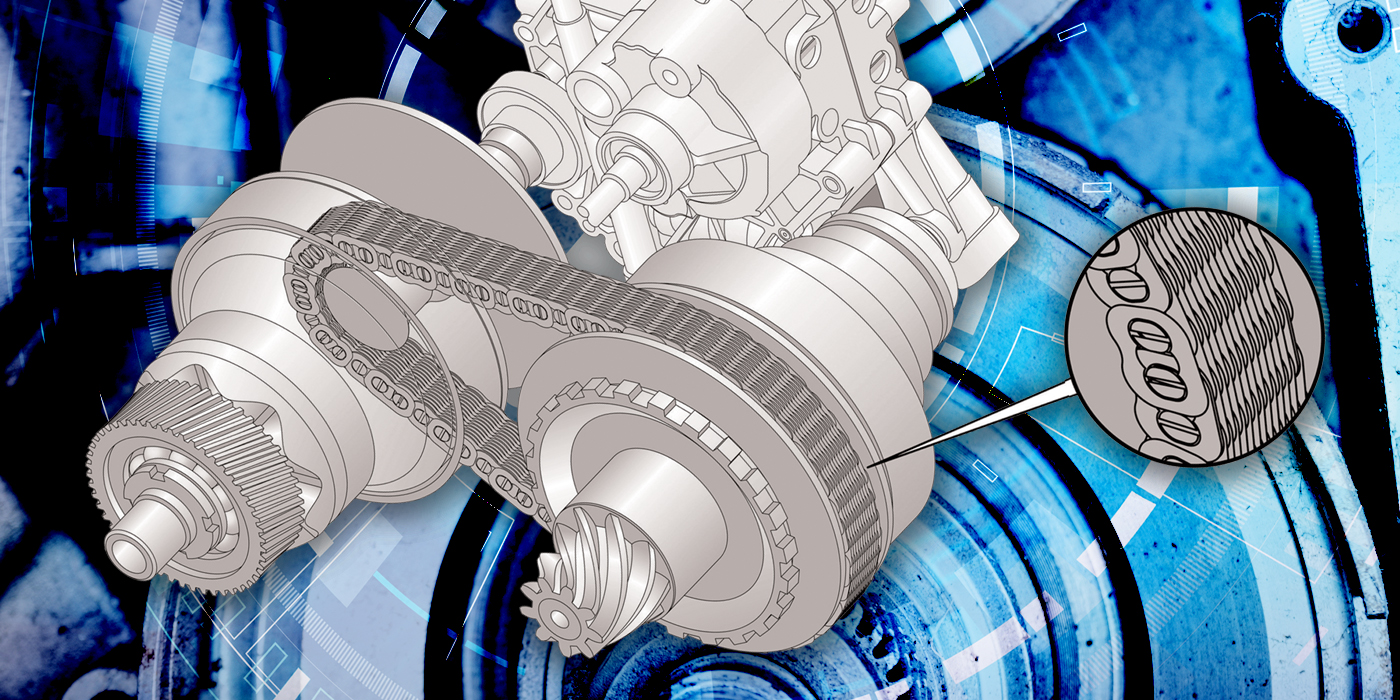

TRANSMISSION FLUID

OE Interval: 80,000-125,000 miles

What has changed? In the past, the fluid would be replaced only when the customer detected a change in how the transmission shifts. But, modern transmissions can mask worn fluid by changing shift points and line pressures. However, even the most sophisticated computer algorithm can mask worn out fluid for only so long. Eventually, the original fluid’s viscosity changes and depleted friction modifiers can damage the clutches and bands. This can destroy a transmission.

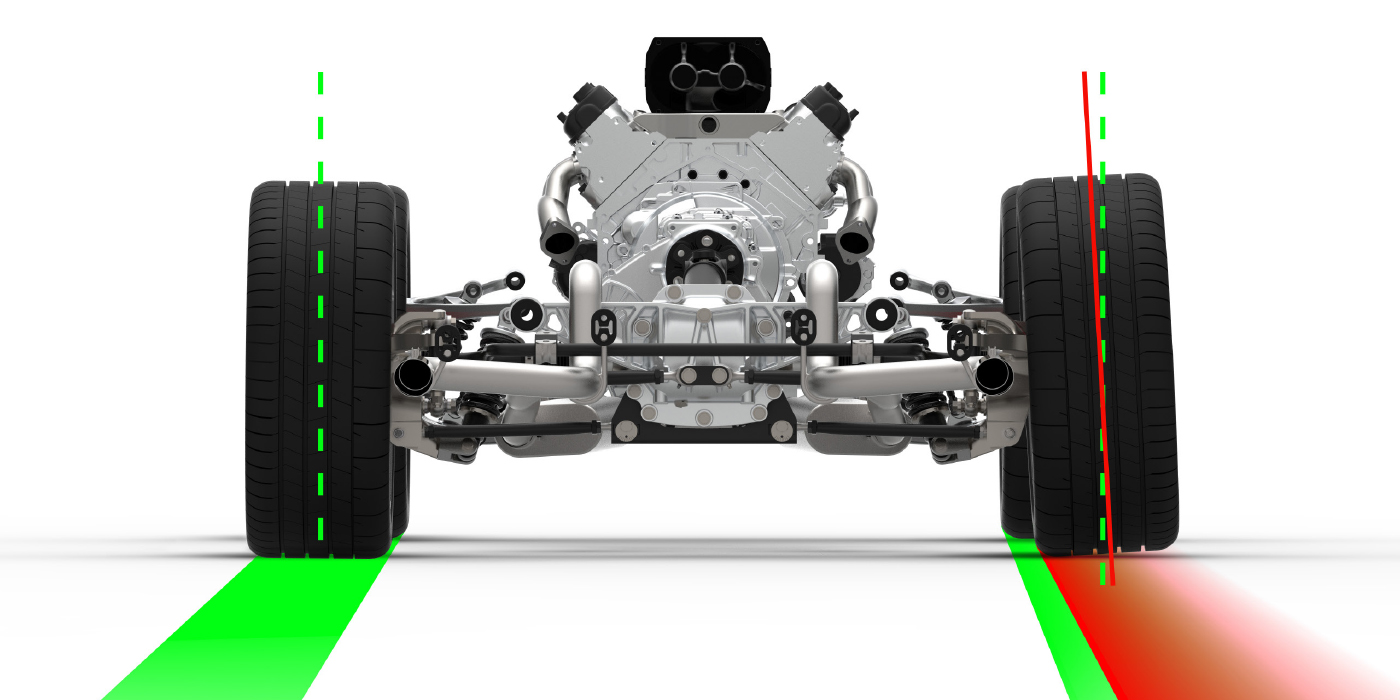

TRANSFER CASES AND DIFFERENTIALS

OE Interval: 60,000 to “lifetime”

What has changed? More vehicles are equipped with AWD transfer cases and differentials with electronically limited slip, locking and torque vectoring technology. They have new fluid requirements and service intervals, so ignoring a maintenance interval could lead to an expensive repair.

Some transfer cases and differentials have a lifetime factory fill and do not require service. If they leak and lose even a small amount of fluid volume, it can be catastrophic for the component.

Fluid requirements for these components can be very specific and require exact levels of friction modifiers to get the electronically actuated mechanical components to function properly.