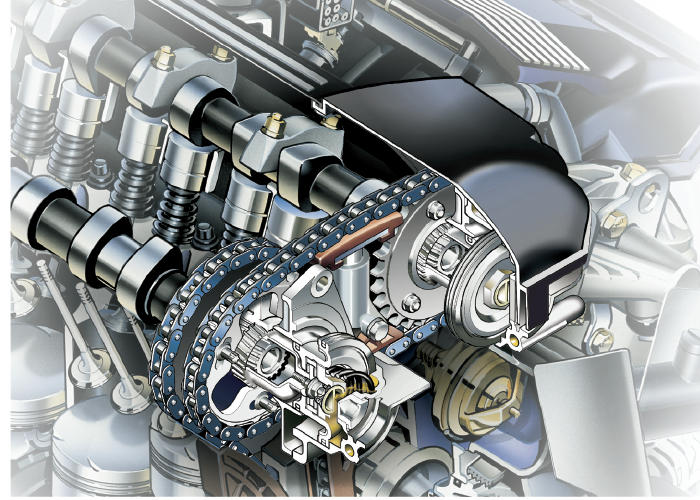

Like many variable valve timing systems, VANOS uses oil pressure-powered actuators to move the camshafts. The actuators need a consistent supply of oil for the correct viscosity, pressure and volume.

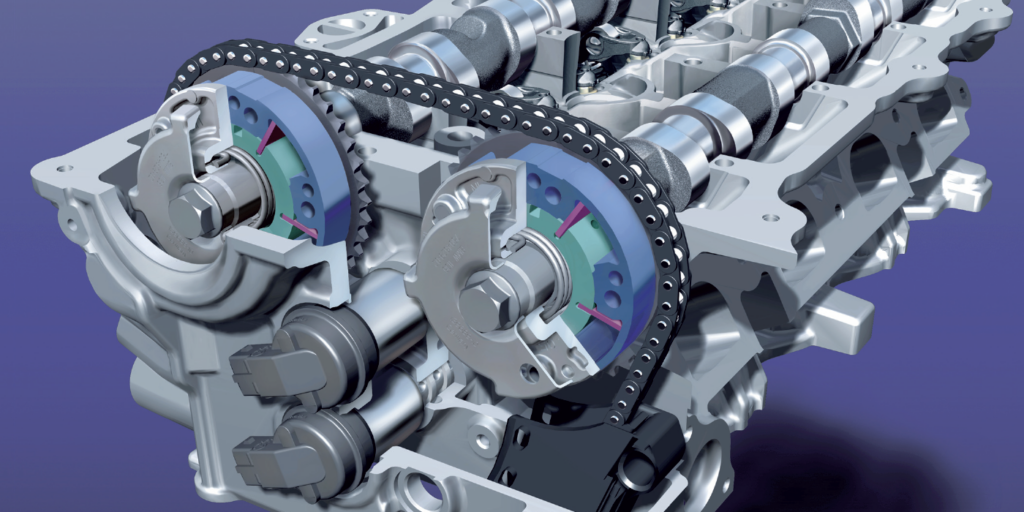

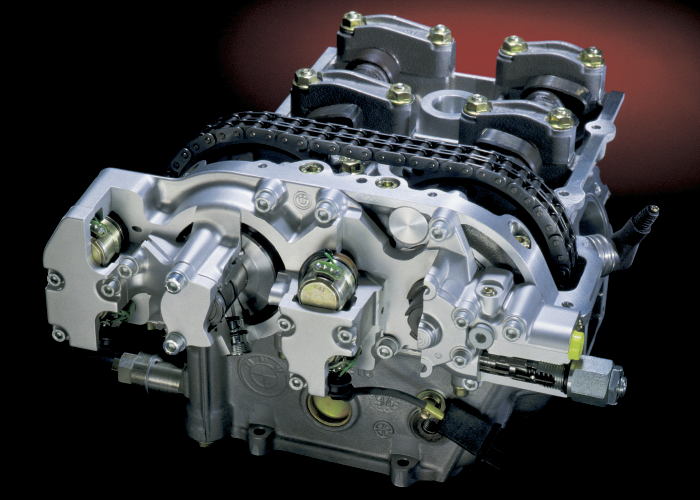

Early VANOS systems use a gear on the actuator and a gear on the camshaft that have angled or helical-cut teeth. The timing is changed by moving the depth of the helical gear on the actuator inside the gear on the camshaft. Connected to the gear on the actuator is a plate or piston with oil pressure on both sides. A solenoid controls oil pressure on either side of the plate to control the depth of the gear.

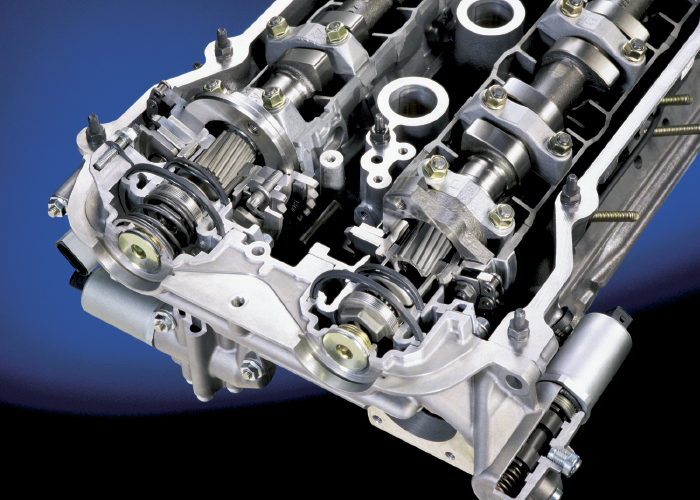

Later VANOS systems use more conventional phases with vanes. This system is very similar to other variable valve timing systems with an oil control solenoid and phaser. The same diagnostic basics apply to these systems. But, like helical-gear actuators, they still require a quality supply of oil to operate.

BMW has used two solenoid designs for dual-VANOS units. For some S54 engines, they use a module with valves that resemble those found in an ABS modulator. The more common design is a spool valve to control the oil on either side of the piston. The solenoid is actuated by a pulse-width- modulated signal.

If the oil is contaminated or is the wrong viscosity, the VANOS system can become sluggish. If the oil pressure can’t move the camshafts to the target positions in a specified time, the camshaft position sensors will sense it and set a code. A code will be set if the actuator and camshaft do not return to the correct position, because they are hydraulically jammed due to oil pressure leaking past a seal.

What Goes Wrong With VANOS Systems?

The two most common failures for a VANOS system are related to the quality of the oil.

The helical gears on the actuator and camshaft can wear. This can cause noise and rattle at idle and startup. The most common failure is when the O-ring seal on the piston wears out and allows oil pressure to move between the two chambers.

This causes the actuator to be stuck or hydraulically jammed in either the full advance or retard positions.

When this happens, the gear can’t fight the pressure exerted on the camshaft by the valve springs. This can cause a rattling noise at startup and idle. There are improved replacement seal kits that use Viton O-rings.

The engine control module sees these malfunctions in the data coming from the camshaft and crankshaft position sensors. In some cases, verifying operation with a scope might be necessary.

If the oil is the wrong viscosity, it can cause the corrections to either retard or advance — in other words, to lag or happen too quickly. These changes take place in milliseconds.

Depending on your scan tool and whether you can pull BMW DME or OBDII codes, the description may include the words jammed, stiff or lagging.

The engine will factor in the oil and coolant temperature into the time allowed for the actuation. If you have any codes related to these sensors, you might want to resolve these issues before troubleshooting the VANOS system.