Applicable model(s)/VINs:

2007-’11 CX-7 2.3L Turbo vehicles with VINs lower than JM3ER******352482 (prod. before Sept. 29, 2010)

2007-’11 Mazdaspeed3 vehicles with VINs lower than JM1BL******398222 (prod. before Sept. 29, 2010)

2006-’07 Mazdaspeed6

With the engine warmed up, some vehicles may exhibit a knocking/rattle type noise from the front timing cover and/or valve (cylinder head) cover below 2,000 rpm.

The noise is caused by excessive stretching of the timing chain.

Repair Procedure:

1. Verify that proper oil change intervals have been performed.

2. Verify that the noise is coming from the front timing chain cover and/or cylinder head area.

Service Tips:

– The noise is heard inside the vehicle with all of the windows rolled up, all accessories turned off and engine running at normal operating temperature.

– The knock pulse is at camshaft speed (1/2 the engine rpms).

– The knock can usually be felt on the No. 3 engine mount.

3. Remove the engine front cover according to the on-line MS3 instructions or the workshop manual.

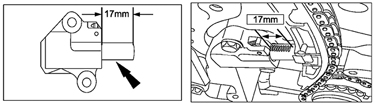

4. Check the protrusion length of the chain adjuster plunger.

– If it’s 17 mm (nine exposed notches) (see Fig. 1) or more, replace the timing chain with a modified one according to the on-line MS3 instructions or the workshop manual.

Note: Do not replace the chain adjuster.

– If it’s less than 17 mm, the noise is not the result of the timing chain stretching concern. Refer to the “Engine Noise” diagnostic procedure in TSB 01-036/10 “Diagnostic Procedure For Engine Noise Repair.”

5. Verify the repair.

Courtesy of ALLDATA.