By Bob Dowie

Contributing Editor

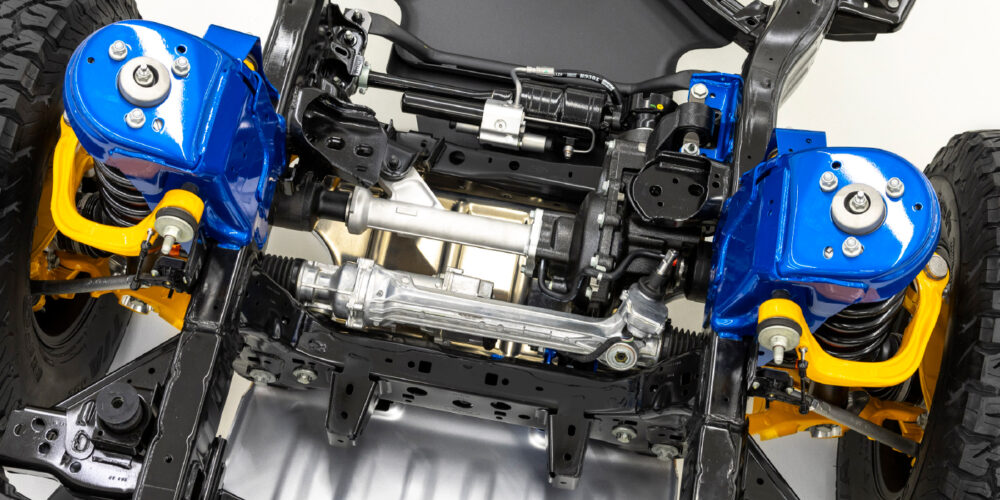

4WD operation can be hard on wheel bearings and seals. The most common complaint you’ll encounter is no 4WD operation, which can usually be traced to problems with the vacuum-actuated front hubs. Some manufacturers require that the driver shift the transfer case into four-wheel-drive, choosing either high- or low-range gearing. The driver must then flip a switch that opens a vacuum-control valve, sending vacuum to the locking front hubs and engaging them to the drive axles. If there’s a weak link in the system, it’s the hubs.

The hubs can cause a couple of problems: The first, and most common, is no engagement. Many times these troubles can be traced to the vacuum supply, rather than a mechanical problem with the hubs themselves. The first step is to be sure you have vacuum at the hubs with FWD engaged and the engine running. If not, work backward looking for the vacuum leak; a convenient test point is the “T” fitting by the master cylinder where the lines branch off to the left and right sides. This “T” is downstream of the control solenoid and vacuum storage tank, so if you have vacuum here, you should have it at the hubs.

Many times, the problem is as simple as broken or disconnected vacuum hoses leading to the hub. But there have been reports of problems with the steel lines running to the wheels. Over the years, these lines can rust, restricting flow and, in the worst cases, causing leaks. There are updated parts available, and Kia has issued a TSB on the subject, but line replacement can be a tedious task. Many techs report good success with alternate methods of repair; you’ll have to make the choice as to what’s the best course of action for your situation.

Another problem you can run into with the hubs involves engagement when it’s not called for. Usually described as a noise, in this case the hubs are sticking, and the wheels are engaging and disengaging the drive, the axles and front differential while the transfer case is in the two-wheel-drive position. Many times, simply backing up the truck will take care of this problem, but often it’s an indication that the hubs should come apart, and be cleaned and lubed. Depending on the condition of the original units, replacement hubs may be in order.

REPLACEMENT HUBS

Should you find yourself in the position where replacement hubs are required, or if the customer values reliability over convenience, consider changing over to the almost-bulletproof aftermarket manually operated hubs. These units provide a low-cost alternative to the automatic units and, while they require the driver to lock the hubs when 4WD is anticipated or required, many customers find it an attractive alternative.

If you do go with the manual hubs, be sure to seal any of the vacuum fittings on the hubs to prevent debris from getting into the hubs, and disconnect the supply solenoid to prevent a manifold leak when 4WD is selected. Removing and replacing the hubs is a simple job that shouldn’t be too challenging for any level tech, but while you’re going in there, it’s a good time to service the wheel bearings or, at the very least, make any bearing adjustment that’s required.

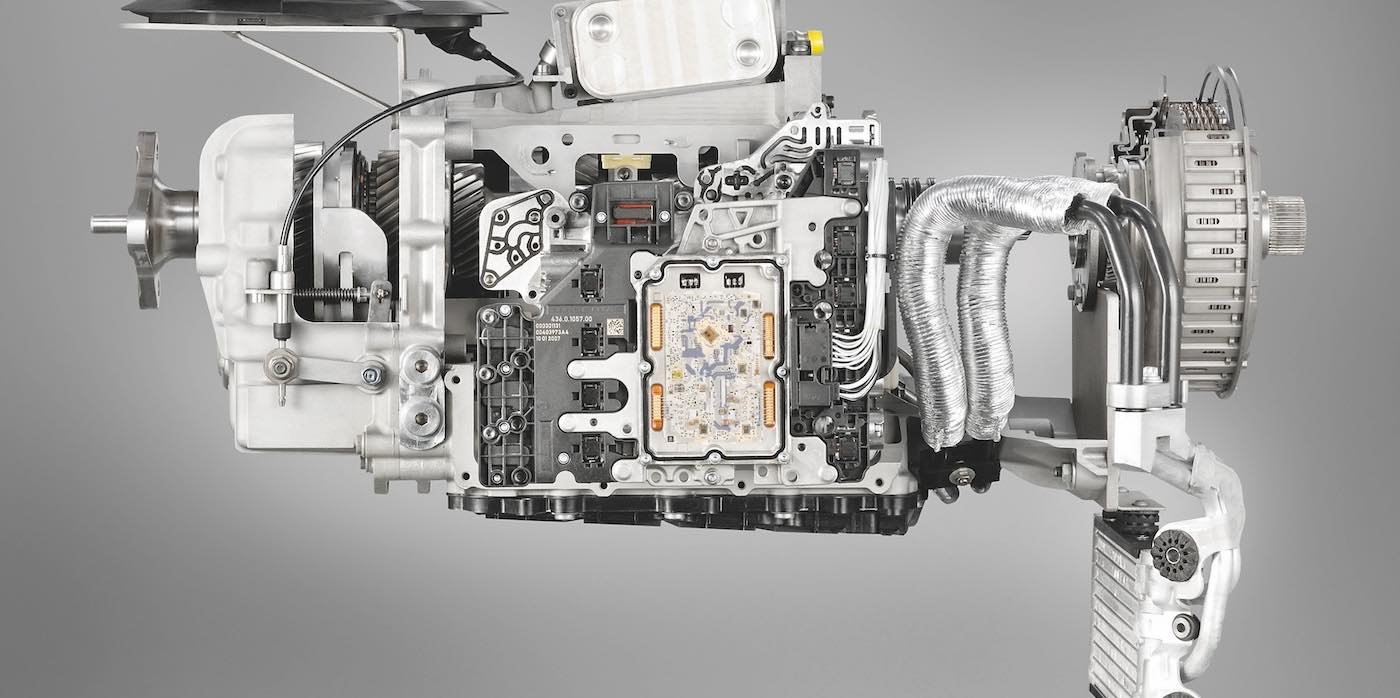

The rest of the 4WD system on these vehicles presents more service opportunities than diagnostic challenges. Be sure to figure on changing the fluid in both differentials as well as the transfer case when doing a major service on a Sportage. Of course, any work on the hubs will have you checking the brakes as well.