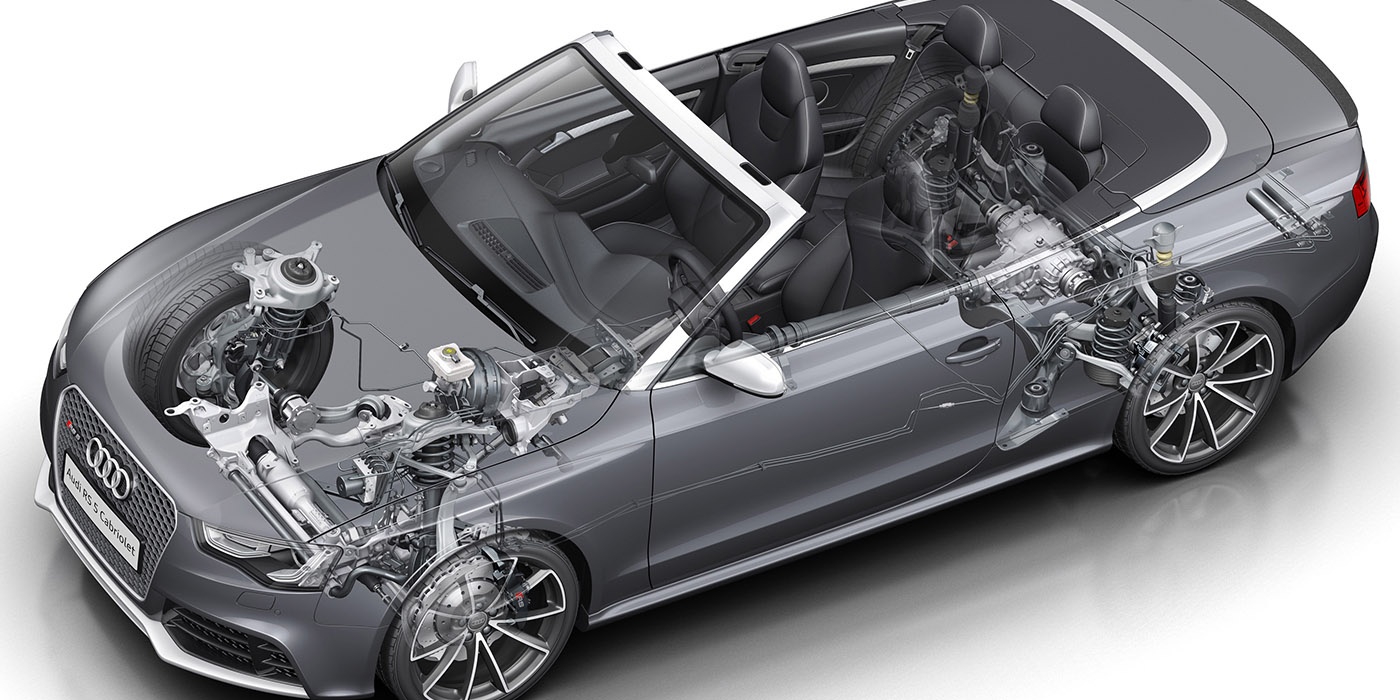

The BMW N53 (naturally aspired) and N54 (turbocharged) engines were among the first BMW engines to come with variable valve timing on the intake and exhaust camshafts. The N53 and N54 straight-six have unfairly earned a bad reputation for reliability with technicians due to timing chain and variable valve timing problems. The reputation comes from owners not keeping up with oil changes and it is difficult to check engine timing.

BMW VANOS Actuators and Solenoids

The latest versions continuously adjust the position of the intake and exhaust camshafts for better power, efficiency and idle performance. The keyword to remember for a late-model VANOS system is that it works “continuously,” and not just under specific rpm ranges.

To service them, you will need the appropriate toolset to lock the crank and camshaft. You will also need a scan tool and scope to observe the crankshaft and camshaft signals to accomplish more advanced diagnostics.

VANOS

Some newer systems can change the camshaft timing by as much as ±72 degrees. Dual-VANOS systems operate at all engine speeds. At lower engine speeds, the VANOS system opens the valves later during the intake stroke, increasing the vacuum and scavenging effect generated by the piston traveling downward in the cylinder. This improves idle quality and smooth power tip-in from a stop. As the engine rpm increases, the valves are opened earlier, enhancing torque as rpm increases. At higher engine speeds, the valves open later for full power delivery so the scavenging effect of the exhaust leaving the cylinder can pull more air into the cylinder. Hot rodders call this “valve overlap.”

The system can augment and even eliminate the EGR valve by allowing some of the exhaust gas to remain in the combustion chamber to control combustion temperatures and NOX emissions.

Also, the camshaft position is changed to reduce engine warm-up times by allowing some unburned fuel to reach the catalytic converters. When the VANOS system on the N53 and N54 is not working, the most common symptoms are poor idle quality, reduced power and poor fuel economy. These symptoms are common to any other variable valve timing system, as well.

How Does VANOS Work?

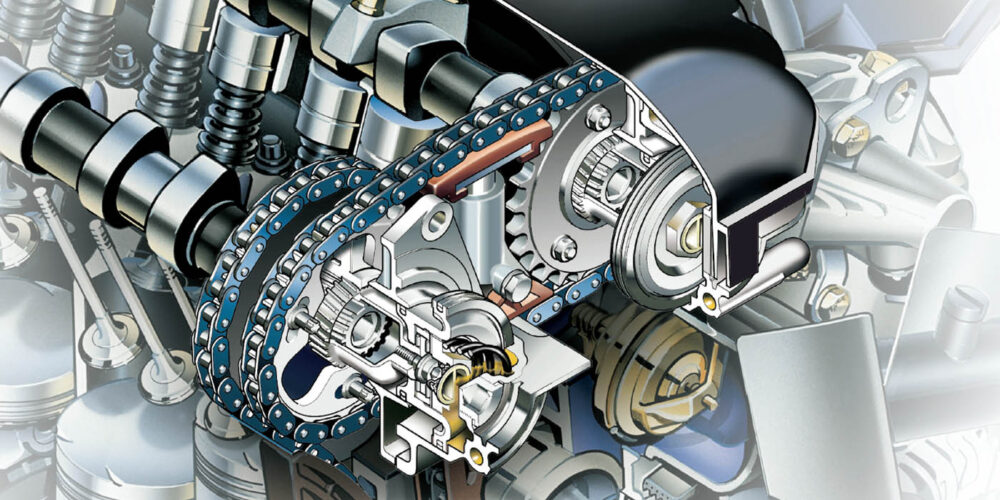

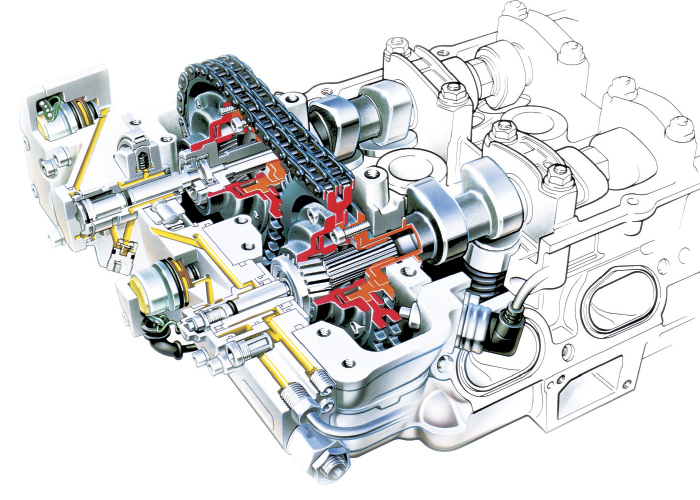

Like many variable valve timing systems, VANOS uses oil pressure-powered actuators to move the camshafts. The actuators need a consistent supply of oil for the correct viscosity, pressure and volume.

The N53 and N54 use a conventional cam phaser with internal chambers that hold pressurized oil that change the position of the camshaft.

BMW N53 and N54 use an oil control valve like a lot of other variable valve timing engines. The solenoid is actuated by a pulse-width modulated signal.

If the oil is contaminated or is the wrong viscosity, the system can become sluggish. If the oil pressure can’t move the camshafts to the target positions in a specified time, the camshaft position sensors will sense it and set a code.

When oil pressure is not present, the camshafts go to a fully retarded position and are locked in place by a pin. A code will be set if the actuator and camshaft do not return to the correct position, because they are hydraulically jammed due to oil pressure leaking past a seal.

Disconnect the oil control valve if you are trying to scope a crankshaft and camshaft waveform. If this is not done, the waveform might look like the timing is out of sync because the engine will be adjusting the camshafts.

What Goes Wrong With N53 And N54 VANOS Systems?

The two most common failures for a VANOS system are related to the quality of the oil. The most common failure is when the O-ring seal on the piston wears out and allows oil pressure to move between the two chambers. This causes the actuator to be stuck or hydraulically jammed in either the full advance or retard positions.

When this happens, the actuator can’t fight the pressure exerted on the camshaft by the valve springs. This can cause a rattling noise at startup and idle.

If the oil is the wrong viscosity, it can cause the corrections to either retard or advance – in other words, to lag or happen too quickly. These changes take place in milliseconds. Depending on your scan tool and whether you can pull BMW DME or OBDII codes, the description may include the words jammed, stiff or lagging.

The engine will factor in the oil and coolant temperature into the time allowed for the actuation. If you have any codes related to these sensors, you might want to resolve these issues before troubleshooting the VANOS system.

Remind your customers that the quality of the oil in both engines matter to the life of their timing chains. BMW recommends a high-quality 5W-30 or 5W-40 that is fully synthetic and meets the BMW Longlife-01 FE specifications. These oils are formulated around the extended oil change interval. When a low-quality oil is used, it can break down before the oil change interval and accelerate wear on the links and pins of the timing chain.