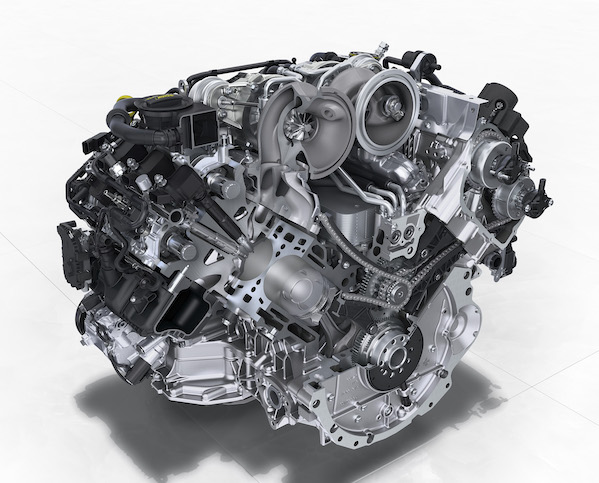

VarioCam and VarioCam Plus are Porsche’s patented variable valve timing and valve lift technologies that have evolved over the past two decades. Originally developed for the 2001 Porsche 911 Turbo, VarioCam changes the valve timing to increase power and reduce emissions.

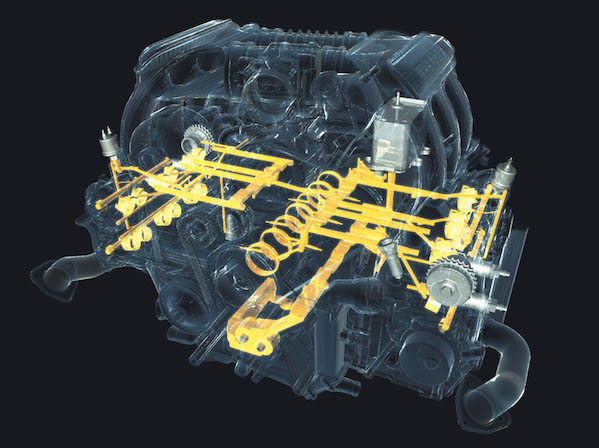

Today, similar technology can be found in every Porsche engine. Early VarioCam systems were one-step systems. In 2004 the 911 Turbo got a fully adjustable vane cell system, as on the 911 Carrera models, the Porsche Boxster and the Cayenne models. VarioCam Plus adds valve lift control and is used on the 911 GT2, Turbo and 911 Carrera models.

VarioCam technology allows adjustment of the camshaft angle and is set to provide optimum performance. For example, in the Boxster, the camshaft angle can be adjusted by as much as 40 degrees compared to the crankshaft, reducing charge cycle losses, improving power, fuel consumption and keeping exhaust emissions to a minimum. In the Cayenne, an adjustment of up to 25 degrees assures a beefy torque curve for the sport utility’s V8 engine.

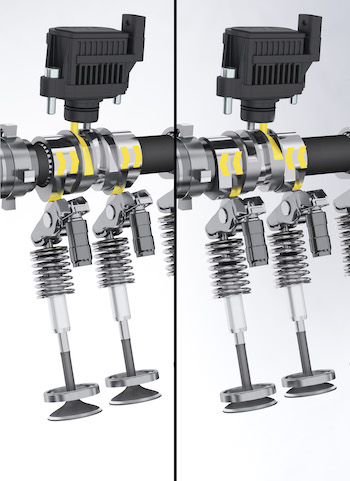

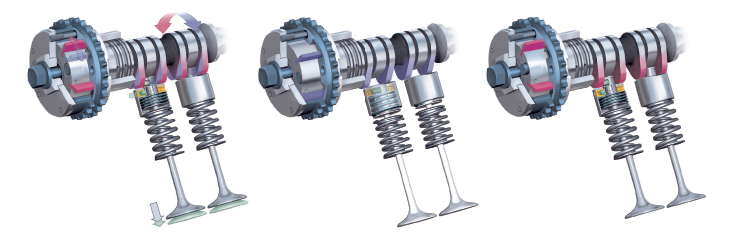

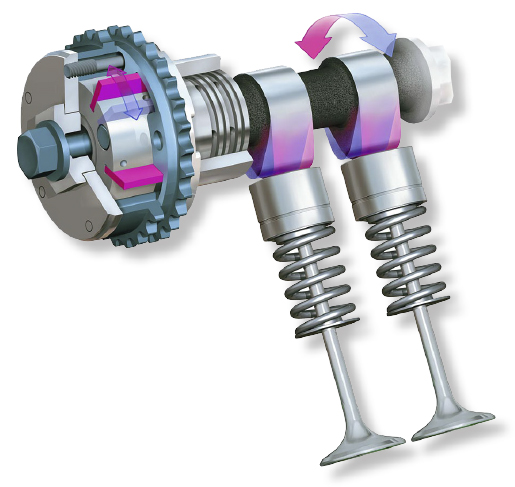

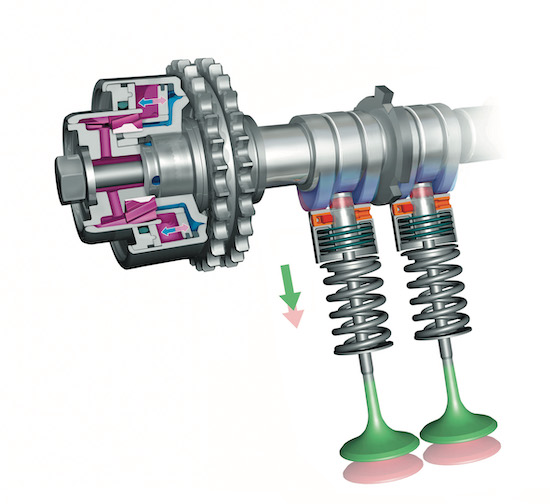

With VarioCam, intake camshaft timing is fully variable through a wing-cell adjuster fit directly on the camshaft drive sprocket. Oil pressure is used to turn the position of the inner wing-adjuster wheel versus the outer sprocket. Because the intake and exhaust camshafts are driven directly via a roller chain, this system makes the conventional three-stage chain drive redundant between the crankshaft and the camshaft.

Porsche’s patented VarioCam responds quickly to any sudden need for power or, conversely, to a more reserved style of driving, such as in city traffic. This is possible because of the way it makes precise adjustments to valve opening and closing times. When running under partial load, the intake camshaft is set to an earlier opening point. The residual gas remaining in the combustion chamber builds up maximum output through the small overlap in the opening and closing times. Maximum torque is provided by extended valve overlap and the earlier conclusion of the intake period. VarioCam Plus not only adjusts camshaft position to provide continuously adjustable valve timing, but also varies valve lift and duration. This helps to flatten as well as smooth the torque curve while reducing emissions.

The use of dual valve springs ensures reliable, high-performance operation. Some have said that driving a Porsche equipped with VarioCam Plus technology is like having two engines in one vehicle: an engine that provides maximum horsepower and torque and another that provides quiet and efficient operation. Even under cold starting, VarioCam Plus improves the engine’s characteristics by reducing emissions through suitable adjustment while the engine warms up. While the engine is at idle, the small cams control valve lift and valve timing is optimized to keep any valve overlap to a minimum.

The small valve lift serves to reduce friction, and thanks to the very short opening times it significantly increases the charge motion while reducing emissions from any previous combustion within the chambers. The system also reduces fuel consumption and emissions by as much as 10 percent. Under partial load, valve lift shifts to a large overlap and the engine runs with internal recirculation of exhaust gases to minimize any throttle effect and to reduce fuel consumption.

Under full load, maximum torque and horsepower are ensured by a highly efficient gas charge cycle with minimum losses as well as an uncompromising cam contour and suitable adjustment of valve opening and closing times.

Engine speed, gas pedal position, engine oil and coolant temperature and even gear selection are monitored. The driver’s commands for horsepower and torque are compared with control maps. Within milliseconds, the computerized system responds and makes the proper adjustments.

What Goes Wrong

If the oil is contaminated or is the wrong viscosity, the VarioCam system can become sluggish. If the oil pressure can’t move the camshafts to the target positions in a specified time, the camshaft position sensors will sense it and set a code. A code will be set if the actuator and camshaft do not return to the correct position, because they are hydraulically jammed due to oil pressure leaking past a seal.

The helical gears on the actuator and camshaft can wear. This can cause noise and rattle at idle and startup. The most common failure is when the O-ring seal on the piston wears out and allows oil pressure to move between the two chambers. This causes the actuator to be stuck or hydraulically jammed in either the full advance or retard positions.

When this happens, the gear can’t fight the pressure exerted on the camshaft by the valve springs. This can cause a rattling noise at startup and idle.

The engine control module sees these malfunctions in the data coming from the camshaft and crankshaft position sensors. In some cases, verifying operation with a scope might be necessary.

Most VVT failures will result in a loss of low- or high-speed engine torque and affect intake manifold vacuum. When the camshaft is not responding to the positions commanded by the PCM, the PCM should store a camshaft-related timing P0340-series error code. On V8 engines, a camshaft timing error on one bank might also result in P0300-series misfire codes for all cylinders on that bank.

Remember that valve timing and valve overlap affect cylinder compression. With a single-bank failure on a flat engine, the bank-to-bank cranking compression should differ, as should the bank-to-bank fuel trim numbers. Keep in mind that with the re-introduction of steel timing chains, a single loose chain or a worn tensioner or chain guide on one bank can retard cam timing and perhaps affect cold starting and driveability performance.

If the oil is too light of a viscosity grade, it can cause the corrections to either retard or advance — in other words, to lag or happen too quickly. These changes take place in milliseconds.

The engine will factor in the oil and coolant temperature into the time allowed for the actuation. If you have any codes related to these sensors, you might want to resolve these issues before troubleshooting the VarioCam system.

Timing chain stretch is not the stretching of the timing chain, it is an elongation of the timing chain caused by wear to the chain’s components. The most common cause of timing chain stretch is lack of maintenance and regular oil changes.

Worn-out oil can no longer lubricate the chain and will cause the rollers and links to wear against each other. As the chain runs around the gears of the camshafts and crankshaft, the movement between the rollers and links causes wear and elongation. Always take a good look at the tensioners. If they are overextended, the chain could be stretched.

As the timing chain wears, this can change the timing of the camshaft and crankshaft. The change in timing is sensed by the camshaft and crankshaft position sensors. This can cause codes that indicate the correlation or synchronization problem with the engine position sensors. On some engines with chain stretch, the guides will be worn due to chain slap.