Understanding how air ride dryers function requires taking a step back in time to your high school physics class. Water can exist as a gas (vapor), liquid and as a solid (ice) depending on its temperature. When air is compressed, it gets hot, and water is converted into its vapor form. The purpose of the air ride dryer is to capture moisture that is released when this air is compressed.

As the air leaves the compressor, it begins to cool. As the air cools and travels through the air ride system, the water changes from a vapor into a liquid because the pressure and temperature have changed. The only thing trapping the water is the dryer.

The dryer on most air ride systems contains a moisture-absorbing desiccant, such as silica or specialized clay. All desiccants have a limited lifespan; they can absorb only a certain amount of water. Once the desiccant is saturated, the air coming into the system is no longer treated, and water can then accumulate in the system.

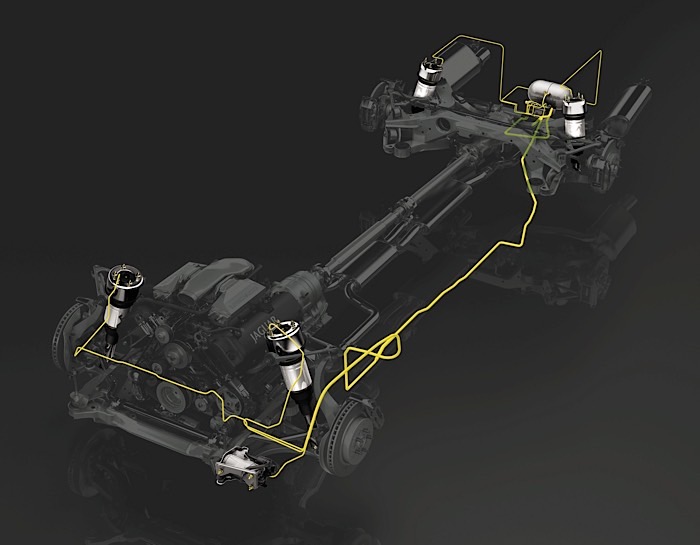

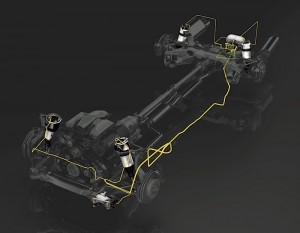

The dryer is typically located after the compressor and before the reservoir. On the majority of import systems, the dryer is mounted on the compressor. The dryer can also act as a cooler to lower the temperature of the air so even more water drops out of the air.

The desiccant inside most dryers is not serviceable. In these units, the entire dryer assembly must be replaced. On units where the desiccant can be replaced, it is advisable to use new desiccant beads. Some beads will change color to a dark blue or purple, while some desiccants will not change color at all.

COLD WEATHER DIAGNOSTICS

Water does the most damage to the system when it is extremely cold. Frozen water can block the lines, preventing the air springs from inflating and the valves in the control block/solenoid from functioning.

On modern electronically controlled suspensions, a customer may report that on a cold morning the suspension was low and did not return to the normal height until the car warmed up for 20 minutes or more. The vehicle may display an air suspension fault message and another message that states, “The suspension is too low.”

This can even occur on vehicles with no detectable leaks in the system. The customer may hear the compressor running, but the system may be making a hissing noise. The hissing noise is coming from the exhaust overpressure valve on the compressor. These are the signs that water has frozen in the lines.

Another common failure can occur when the exhaust port freezes. This may cause the vehicle to ride higher than normal. This failure is more common with older air ride systems that “trim” the vehicle using height sensors rather than pressure sensors.

Modern air ride systems can detect problems such as a blockage. The system will stop running the compressor if it can’t detect changes in the reservoir pressure as the compressor is running. If it detects a problem, the suspension will go into a fail-safe mode that will try to trim the vehicle to a safe ride height while minimizing compressor temperatures.

SOLUTIONS

Removing water from an air ride system requires some disassembly. Removing a line at both ends and blowing it out with shop air is one method. Removing and draining the air reservoir can also help remove a large amount of water that may have accumulated in the system.

Do not try to use methyl alcohol to flush out the water. This can damage plastic and rubber components in the air ride system. It may also leave behind more liquid in the system than what was removed.

The best bet is to replace the dryer and let it do its job of removing the excess moisture in the system.