This car started as a WRX/STi and has been modified by Z Sport (www.zsport.com) to provide a balanced machine that can work as a commuter, ski transporter and quick grocery getter, as well as a full performance vehicle. The total package comes out as being a comfortable, AWD four-door sport sedan that performs like a sports car under any condition and in any weather. This is not a “dyno queen,” as Damewood drives the car back and forth to work every day.

In the previous article (November 2009 ImportCar, pages 40-48), I touched on some of the suspension and chassis modifications that are on this car. In this article, I will be detailing those modifications and providing some ideas on future upgrades that are planned.

Project cars take time and often involve changes that, in the end, do not provide the desired result. In those cases, other products or procedures might be needed if a different outcome is desired. Consider this article as a guideline, keeping in mind that you or your customer may have a different idea about the desired effect of any modification.

It’s important to keep safety and design limitations in mind when making any modifications. And prevent comebacks by using quality components from well-known suppliers with certifications that the components meet or exceed OEM specs. As with any modification to a customers’ vehicle, time spent before the work explaining and determining what is expected will prevent having disagreements or disappointments after the work is completed.

FRONT SUSPENSION AND STEERING

Just lowering the suspension and adding wider tires is often the extent of suspension tuning. Taking a basic approach when you’ve just added twice the horsepower (see Photo 1) is a mistake, waiting for an accident to happen. This car has had virtually every suspension component modified for better attachment, consistent movement and response, or more serviceability and adjustment.

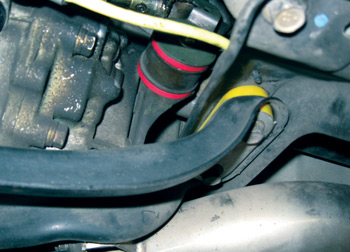

First, every removable or replaceable bushing (see Photo 2) has been swapped with urethane or factory Group N (made for the Japan home market with a harder compound) from a number of suppliers. Whiteline urethane suspension and steering rack bushings (www.whiteline.com.au) control unwanted flex that makes consistency in handling difficult. Their tie rod ends and ball joints (see Photo 3) also allow more adjustability and provide additional offset for setting the alignment to the desired specs.  Urethane engine and transmission mounts (see Photo 4) actually help stiffen the overall structure of the car without imparting much additional vibration or noise transferred into the body.

Urethane engine and transmission mounts (see Photo 4) actually help stiffen the overall structure of the car without imparting much additional vibration or noise transferred into the body.

A Hotchkiss sway bar (see Photo 5) with solid/adjustable end links, greasable mount and end link bushings are used for keeping the car level on turns. Perrin (www.perrinperformance.com) PSRS rear control arm mounts (see Photo 6) are used in addition to the offset ball joints to provide a change in geometry that controls nose dive and lift on acceleration. Wheel spacers are used to widen the track slightly to allow the use of larger wheels and tires, and the extra adjustability in the suspension helps maintain proper tire contact under all conditions.

The shocks (struts) are fully adjustable Tokico D-spec (damping-specific) gas assemblies. Upper mounts are urethane; the current springs are Cobb. A change to Tein or Eibach progressive springs will be made in the near future. Adjustment of the strut valving is made possible by removing a small cap (see Photo 7) at the upper mount and turning the adjuster with the supplied tool that can be attached to your key chain. The adjustment provides a noticeable change in suspension control while allowing full suspension travel for comfortable cruising or flat out competition.

REAR SUSPENSION

The rear struts are again the same Tokico D-spec units (see Photo 8) that match the front set. The main difference is that the adjusters have been remotely mounted to the package shelf. The same tool is used after removing the cap just behind the seat (see Photo 9) and the adjuster is turned through the extension to change the suspension tuning. A spring change in the future will be matched to the front.

Urethane or factory N-spec bushings are used here as well. Damewood indicated that a front strut bar is not really needed due to the strength of the front body structure. The rear is not so strong. Using a crossbar in the rear (see Photo 10), along with a rear suspension lockdown system, adds significant strength to the whole rear structure. The crossbar  mounts in the front part of the trunk and takes up some space. But the difference can be felt on any uneven surface. The bolts for the lockdown system pass through the rear suspension carrier into the body (see Photo 11) and remove a significant amount of movement from the rear subframe.

mounts in the front part of the trunk and takes up some space. But the difference can be felt on any uneven surface. The bolts for the lockdown system pass through the rear suspension carrier into the body (see Photo 11) and remove a significant amount of movement from the rear subframe.

The Hotchkiss rear sway bar has the same greaseable mount bushings, and well-designed cast aluminum end links (see Photo 12) that replace the factory plastic ones. These links are adjustable to allow heavier or lighter loading of the bar. There are more zerk fittings on this car than I have seen since I owned a Studebaker!

OTHER FEATURES

Everywhere you look on this car, there has been a part modified or replaced. Unlike a lot of project cars, however, every component has been selected with an eye toward functionality and reliability. Some changes were necessary due to the modifications, like the really nice looking reservoir unit (Weapon R) that replaces the washer fluid bottle. This unit was  needed when the larger intercooler made it necessary to move the radiator back slightly. The factory cool-ant reservoir could no longer be mounted to the shroud. This aftermarket piece solves the problem by combining the coolant and washer reservoirs into one good-looking unit (see Photo 13).

needed when the larger intercooler made it necessary to move the radiator back slightly. The factory cool-ant reservoir could no longer be mounted to the shroud. This aftermarket piece solves the problem by combining the coolant and washer reservoirs into one good-looking unit (see Photo 13).

The Garrett turbo installation looks great (see Photo 14). Every part serves a function and looks good at the same time. The fuel pressure regulator (see Photo 15) now is part of a fuel rail system by Agency Power that allows a much higher fuel rate when the demand requires maximum flow. An adjustable wastegate provides protection for the engine while allowing maximum boost.

FINISHING UP

I expect that in the next month or so, the engine management issues will be resolved and, with the engine fully broken in and sorted out, we can get some real numbers on the actual horsepower increase. As soon as I get those numbers I will send them for publication, so stay tuned for future developments on this car.