More and more vehicles are using remote keyless entry, or proximity keys and push button start systems. While these features offer a lot of convenience to customers, they can present their own unique challenges to us as technicians. The ability to diagnose and service keys is quickly becoming an essential skill, especially as these vehicles start to come out of warranty.

So, are you prepared to diagnose a faulty key fob as the reason why a vehicle won’t start? What if the engine will start, but won’t run for more than a few seconds? What if the customer says that their doors won’t unlock, or they can’t cycle the ignition with the engine start button? What do you need to do to program a key to the vehicle after a module has been replaced? And, finally, how does the key affect the immobilizer system, and how do you determine if the key is to blame? Let’s dig in, shall we?

Remote Keyless Entry (RKE) vs. Keyless Entry and Start System (KESSY)

We will be focusing our attention on Volkswagen’s Keyless Entry and Start System (KESSY), but first we need to talk about its Remote Keyless Entry System (RKE) and how the two systems compare. Let’s start by identifying which one you’re working on, which is quite simple.

RKE vehicles will have a flip out key and an ignition switch on the steering column (Photo 1). The key needs to be in the ignition switch in order to start the engine in an RKE vehicle. KESSY vehicles won’t have a traditional ignition switch on the steering column; they utilize antennas inside the column and a push button which cycles the ignition and starts the engine (Photo 2). A KESSY vehicle needs the key to be present only inside the vehicle in order to start the engine.

The keys may look different as well. An RKE key will typically have a flip out key blade, and a KESSY key likely will not. A KESSY key may still have a key blade, but it could be internally mounted. To release this type of emergency key blade, simply press down on the VW emblem along with the release latch under the top of the key.

How Does the KESSY System Work?

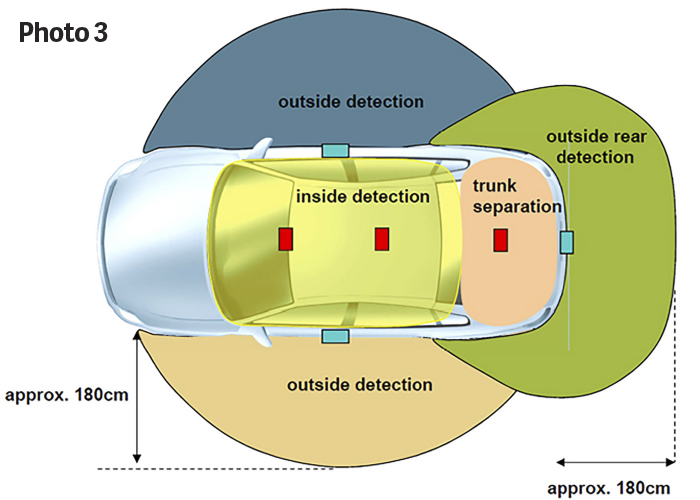

Both types of keys have built in remotes for unlocking and locking doors, but you don’t need to unlock the doors to get into a KESSY-equipped vehicle. The key acts as a low-frequency (LF) transmitter, and the vehicle has several antennas (red boxes in Photo 3) which look for the unique ID signature of the key. The doors will automatically unlock after a key is detected in one of the outside detection zones and the door handle sensor is touched (blue boxes in Photo 3).

The vehicle will also have detection zones inside the vehicle. If a key is placed inside the trunk and the trunk lid is closed, the trunk may pop open again to prevent the key from accidentally being locked inside. The antennas inside the vehicle cabin allow the vehicle to be started using the push button start.

A number of control modules and components are used to operate the KESSY system. This may include the Access/Start Control Module (J518), Central Control Module (J393) or Electrical System Control Module (J519, also known as the BCM), Door Convenience Control Module (J386), and the Steering Column Lock Actuator (N360). These modules may be used to power other convenience features including priming the fuel pump when a door is opened or unlocking the doors and turning on exterior lights when approaching the vehicle at night.

But, at the heart of the KESSY system is the key itself. If the key isn’t functioning properly or if an antenna can’t detect it, you could be left chasing your tail trying to diagnose the problem.

What About the Immobilizer?

Volkswagen’s immobilizer system (IMMO) is used to authenticate or reject the key. The IMMO is not a part of the vehicle alarm system, and it won’t prevent the engine from cranking over – at least not initially. If the IMMO doesn’t authenticate the key, it will shut the engine off within 1-2 seconds. If the engine shuts off after five seconds or more, the IMMO may not be to blame.

KESSY Diagnosis

So, you’ve got a customer vehicle in your bay with an RKE or KESSY issue: where do you start?

As always, you’ll need to replicate the complaint. Maybe the key starts the vehicle, but the engine shuts off after 1-2 seconds. The doors might not unlock with the remote, or only the driver’s door unlocks. Does the customer have the “Convenience Opening” feature enabled in the vehicle?

If you can replicate the complaint, scan the vehicle for fault codes. Test whether or not the door locks will work using the switch on the door panel. The door lock actuator could be faulty, and the customer may not have thought to try this.

Next, look at the OEM service information and search for TSBs. Check the simple things such as fuses and the wiring! If a control module appears to be faulty during diagnosis, be absolutely sure that the harness isn’t damaged. Replace any faulty or damaged wiring before proceeding with diagnosis.

If you suspect that the battery inside the key is discharged, try holding it up against the sensor ring on the steering column (Photo 4), then push the engine start button. The RFID chip inside the key will be inductively powered by the RFID coil inside the steering column, and IMMO should then authorize the key and allow the engine to run. This works as a backup method for starting the vehicle if the battery inside the key is dead.

What Tools Will You Need?

Programming the key fob or remote will require a scan tool. VCDS will work fine if you have access to it, but there are also alternative aftermarket programming tools available.

As for the physical key itself, long gone are the days of needing locksmiths or specialists to help with key cutting (Photo 5). These days you can typically find a number of dealerships, brick and mortar locksmiths, or hardware stores near you, all of which should be equipped to cut key blanks. However, it’s up to you to get them programmed to the vehicle. If the vehicle uses proximity keys there might not be a key blank to cut, or you might be able to transfer the key over to the replacement unit.

You’ll also need specialized equipment to check the battery inside the key. “TSB 57-19-02 – Remote Key Battery Replacement” outlines this procedure. To summarize, if the “Remote key voltage too low” codes are present in the BCM, the battery needs to be tested to determine whether or not it is discharged. But, hooking up a DVOM across the battery won’t tell you what you need to know. The only way to accurately test the voltage is to provide resistance (approx. 320 Ohms) across the battery. This means you’ll need specialized equipment including the VAS 6345 resistor decade and VAG 1594/19A extension leads (Photo 6).

Get With the Program

The vast majority of key programming procedures will require the vehicle to be put into a learn mode; this is typically called “onboard” programming. For most late-model vehicles, it’s more about programming the vehicle to recognize the key, rather than programming a key to communicate with the vehicle. The actual process of programming the key to the vehicle is rather simple.

During this process, data can travel both ways. Information from a key can be programmed into a module, or information from an existing model can be programmed onto a key. This could be helpful if a module has been replaced or reflashed and the key information is lost, or if all of the keys have been lost.

Onboard procedures use the antenna coil on the vehicle to read the transponder or ID number in the new key or remote. The vehicle gets the key’s transponder to transmit, and the unique ID is learned by the vehicle during the procedure. Once that “handshake” is complete, the key is programmed and good to go!

It’s worth noting that some late-model vehicles may require a three-to-four-digit PIN code to start the onboard programming procedure. This code resides in the module for the immobilizer system (IMMO ECU), or in the Body Control Module (BCM). You may also be able to clone the key transponders in the vehicle’s memory using specialized equipment.

Best Practices

Whenever possible, scan the vehicle for fault codes before starting the key programming process. This could help to identify defects or faults in the system which might prevent you from successfully completing the procedure. Ensure that the vehicle battery is in a healthy state of charge. Be sure to have both the original keys, and any replacement keys nearby, and follow the on-screen prompts throughout the process.

So, what did we learn? With a small investment in tools and a bit of research, you can easily add programming keys to your list of available services. You could also become more effective when trying to diagnose a no-crank, no-start condition, now that you know how critical the key is to that process.