In the automotive aftermarket, not all parts (or parts manufacturers) are created equally.

This isn’t a bad thing, considering that there is a time and place for parts of all different qualities, materials and price points – dependent on the driver’s needs and budget.

But did you know that in the aftermarket, there are parts manufacturers who actually produce product which is better than OE quality? That’s where the term “ultra-premium” comes in.

What Does Ultra-Premium Mean?

Simply put, ultra-premium means “better than the best” quality. This means often surpassing the quality, fit and performance of the comparable OE product.

Ultra-Premium Parts Should Possess the Following Qualities:

1. Superior engineering

2. Advanced manufacturing techniques and practices used by the OE, or better

3. Product materials used by the OE, or better

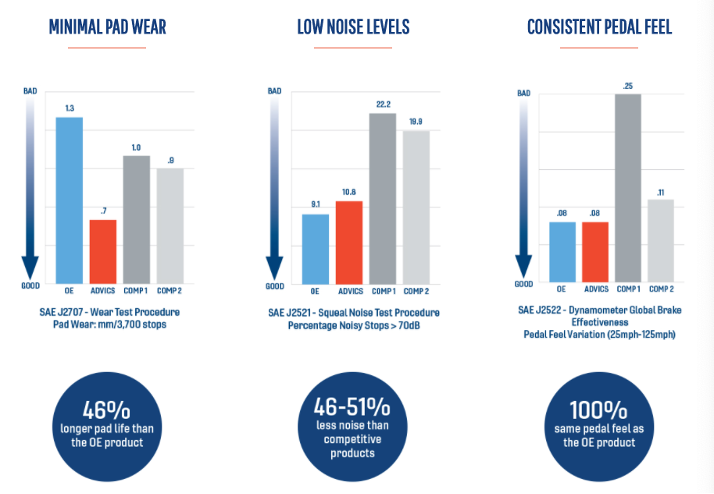

4. Rigorous product testing with data to support the results

5. Fit, form and function at the OE level, or better

Ultra-Premium Quality and Brake Parts

So what does ultra-premium mean in the world of brake parts? Let’s use brake pads and brake rotors as an example.

Brake Pads

Brake pads typically come in three different styles of friction material: organic, semi-metallic and ceramic.

Organic friction material is typically a combination of glass, Kevlar, carbon, rubber or fiberglass, and the compounds are bound together with heat-resistant resin. These brake pads are typically the most economically priced and produce good stopping power, but due to the blend of materials, they also produce a lot of black brake dust and tend to wear down fast.

Semi-metallic friction material is a good option, containing a combination of iron, copper, steel and graphite. These pads produce good performance and heat transfer, and are much more durable than organic brake pads. They are also cost-efficient, falling in between organic and ceramic pads.

Ceramic is the best quality when it comes to friction materials, made predominantly of stacked glass ceramic fibers, with only a small amount of filler agents and mixed metals in the compound. These brake pads produce a great stop and heat transfer, while being quieter and cleaner than organic or semi-metallic brake pads.

Brake Rotors

Brake rotors are an essential part of the braking system, responsible for taking the pressure from the caliper as it squeezes the friction across the rotor’s surface, so they need to be strong. The material from which a rotor is made plays a major role in the performance of the part.

Disc brake rotors typically come in three categories: economy, standard and premium.

Economy rotors are at the lowest price point and typically made from scrap iron. From batch to batch, quality can be inconsistent, and this can lead to hard spots on the rotor’s surface which may cause warping, pedal pulsation and noise – putting unnecessary stress on the rest of your braking system.

Standard rotors are typically made of a cast iron material and are the most common type of rotor available. While popular, they are heavy and may impact vehicle handling, depending on the driving application. Standard rotors produce good stopping power and you can typically avoid the warping and overheating issues that can come with use of a cheaper, economy option.

Premium rotors can be made from several materials. Certified high-carbon rotors are one example. High-carbon rotors are still made from cast iron, but have high levels of carbon mixed in. This addition of carbon means the rotors withstand much higher braking forces, are durable against cracking and also produce excellent NVH performance. They are also able to dissipate heat quickly and withstand tougher driving applications.

Manufacturers offering ultra-premium parts go even further than high-carbon content. This can be done by adding in a proprietary design that creates suction to remove hot air and gases from the rotor’s surface, coating the rotors in anti-rust compounds, C40 and E-Coating and using OE quality disc plates. These factors combined results in a rotor that is truly ultra-premium and better than the aftermarket competition.

The Bottom Line

When purchasing parts for your shop, quality should be a top consideration. By stocking your shop with ultra-premium brake parts, which are designed to work together, you ensure that your customers are leaving with an OE-quality braking system.

This means they enjoy the aftermarket’s safest stop, and you enjoy a job done right the first time.

This Article is Sponsored By: Advics