Ever since the first issue of BRAKE & FRONT END in 1931, the magazine has fought the fight against price point brake jobs and the inferior materials that are inevitably installed as part of the job. During this period in the Great Depression, you could get all four brakes relined for $19.99 (springs and hardware extra).

Ever since the first issue of BRAKE & FRONT END in 1931, the magazine has fought the fight against price point brake jobs and the inferior materials that are inevitably installed as part of the job. During this period in the Great Depression, you could get all four brakes relined for $19.99 (springs and hardware extra).

If you calculate what that means in 2011 dollars, it would cost $282 according to the Consumer Price Index. So why are shops performing $99 brake jobs? Why has the $99 brake job stuck around for more than 20 years ($156 in adjusted 1991 dollars)? Have shops devalued themselves that far? Do we have low self-esteem? Is it just a product of competitive pricing? Or is there something more sinister at play?

Brakes are not a loss leader. It is not a service like an oil change or filter replacement that is used to bring vehicles in for service so you can spot other worn or broken parts that need to be repaired. It is a safety service and the consumer should be charged accordingly.

So what does it take to get undercar shops to get out of the $99 pad swap doldrums? Just like in the 1930s, the shops that will survive are able to put a value on brake service for the consumer and are able to charge more than $99.

There is no way to measure a rotor for thickness and runout efficiently and profitably on a $99 brake job. Between setup and making the measurements, it takes at least 10 minutes. But, this must be performed even if you are just slapping in new pads.

Don’t trust the OEM and their service information when it comes to pad replacement procedures. Most of these procedures are designed to save them warranty related charges and not return an out-of-warranty vehice to optimal operating condition. If a engineer got their way, they would recommend performing a light cut on the old rotors. Even if the rotors are within specification, a light cut and non-directional finish can provide a finish that can improve the bedding-in process and reduce stopping distances. It can also reduce noise-related comebacks.

Selling Pads

The brake repair market is starting to become dominated by a “good enough” mentality when it comes to $99 brake jobs. Good enough to some is just being able to stop in a “reasonable” distance at normal driving and last for 20,000 miles. But, when asked to perform an emergency stop or a series of hard stops, the vehicle can become unsafe with longer stops and a low pedal. You may rationalize that your customer may never perform such severe maneuvers, but how can you be sure?

Are you sure that little old lady does not drive with two feet? Can you be sure that that a truck will never tow a boat? Is it really worth installing cheap brake pads in order to be able to advertise and hopefully make profit on a $99 brake special?

What standards should you have when selecting replacement brake pads? Try them for yourself! Set aside some time when the shop is not busy or on a weekend to try out the brands of brake pads you install. Perform at least four emergency stops from 55 mph to a dead stop back to back. Let your right foot be the judge. A series of hard stops will simulate the punishment a pad might have on a major metropolitan freeway during extreme stop and go traffic.

Inferior brake pads will start to fade and pedal travel will be almost to the floor. Or, look at the pedal travel data on the 2nd hot stop of the FMVSS (Federal Motor Vehicle Safety Standards) test. It is the friction level that provides the deceleration torque to stop the car, but it is the pedal travel or fluid displacement that actuates the brake and is required for proper ABS functionality. If the fluid displacement increases to much, it can dramatically inhibit the response of the anti-lock brake system.

Also, inferior pads will start to smell worse than the average burnt clutch. Some inferior brake pads may have a very acrid or pungent aroma due to the use of cheap glues and fillers. Also, the smell can be attributed to coatings and paints that may be burning.

Some friction companies will cut corners at the shop’s expense. Some inferior brake pad manufacturers use only a handful of friction material formulations across an entire product catalog. This means that the same friction material may be used on a SUV and compact, the only thing they change is the backing plate. This can lead to compromises and may even influence the braking balance front to rear.

Selling Hardware

Selling Hardware

Even if you were using child labor from the 1930s, could you make a profit on a $99 brake job if you install new hardware? New hardware is critical to protecting the driver’s investment in a proper brake job.

Brake hardware for disc brakes is not a dealer-only item. Your local jobber might carry three lines of hardware. This product category is more than shims, anti-rattle clips or dust shields. Many of these lines of products include items like caliper brackets, slides and all the soft parts to restore the system to like-new condition. Many of these parts are at reasonable prices that you and your customer cannot refuse.

Heating and cooling cycles can weaken springs and anti-rattle clips. Weak hardware parts can result in excessive caliper/pad movement or binding causing noise and other related problems. This can lead to uneven and premature pad wear, rotor warpage and pulling.

Some springs and clips can be difficult to install. Some anti-rattle clips may resemble Chinese finger traps when you are trying to reinstall them back on the car. But leaving them out is not an option.

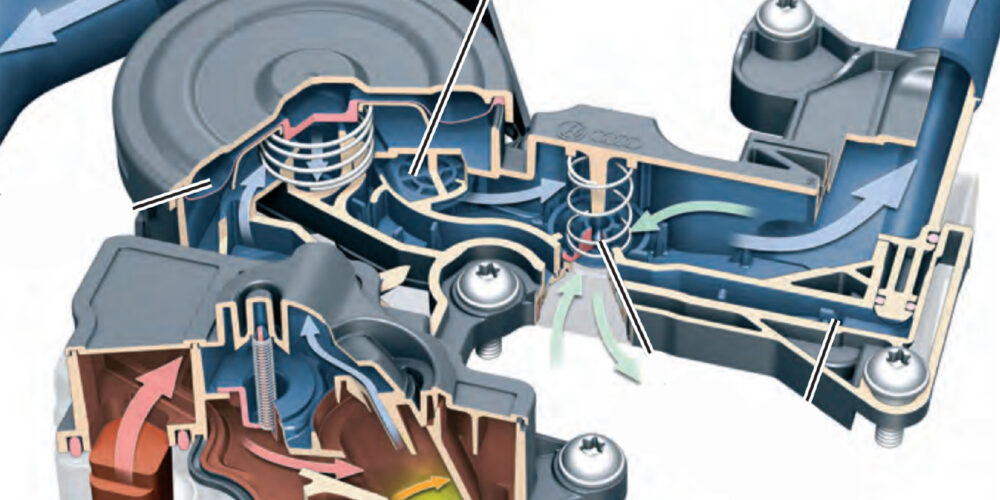

When rust and corrosion build up on a floating caliper’s slides or bushings, it can prevent the caliper from centering itself over the rotor when the brakes are applied. Not only does this reduce effective braking force and increase the vehicle’s stopping distance, it also causes uneven pad wear.

The same condition may also create uneven braking between the right and left calipers, causing the brakes to pull toward the stronger side.

When technicians think of brake hardware, they think springs, clips and slides. But soft parts like dust shields, grommets and bushings need just as much attention.

Most floating brake calipers use a rubber or plastic insulator or shim around the mounting bolts of the caliper. This sleeve of soft material loses resiliency over its lifetime. This is hastened by the high-temperature environment of the brakes. As materials wear, instead of being round they are flattened by the torque from the brakes into an oval shape that can cause excessive caliper movement. This can cause noise like rattles and thumps even if the brakes are not applied.

Most floating brake calipers use a rubber or plastic insulator or shim around the mounting bolts of the caliper. This sleeve of soft material loses resiliency over its lifetime. This is hastened by the high-temperature environment of the brakes. As materials wear, instead of being round they are flattened by the torque from the brakes into an oval shape that can cause excessive caliper movement. This can cause noise like rattles and thumps even if the brakes are not applied.

Lubricants

To perform a $99 brake job, you can not clean and lubricate the caliper guide pins. You only have enough time to pull one pin, rotate the caliper, push the piston back, replace the pads and then follow the reverse steps.

Brake lubricants are critical in returning the brake system to optimal operating condition. Failing to clean and lubricate is like never cleaning a gun; you just know it will jam on you some day.

There are three criteria to remember when selecting a brake lubricant.

First, does it say that it’s a brake lubricant on the package? If not, do not use it. Some lubricants may say they are a silicone or molybdenum disulfide based, but they may not be formulated to work on brakes. Second, look at the effective temperature range of the lubricant. At minimum, a lubricant should be able to handle 400° F. Third, check to see if it contains petroleum distillates or any substance that can be detrimental to soft parts.

It takes at least 7 minutes to perform a proper brake job test drive. Even line techs at dealerships get paid to perform this procedure. Just backing the car out of the bay can cause a comeback and leave service dollars on the table.

A test drive can ensure the brake system is operating properly. It can also help you to spot other problems with the vehicle.

The other reason a test drive must be performed is to mate the pads to the rotors. This can be called “break in” or “burnishing” the pads. Burnishing also can help to transfer a layer of the friction material onto the rotor. Some manufacturers call this transfer-layer technology and it can help to increase the life of the rotor.

The number of stops a technician should make will vary. Also, check the box or with the manufacturer for their recommended burnishing procedure. This can help to prevent the customer from experiencing a burning smell when they first apply the brakes for the first 100 miles. When you deliver the vehicle to the customer, advise them not to do any severe braking for the first couple of hundred miles.

Some are also “pre-burnished” to eliminate many of the problems that can occur if the pads are not broken in properly.