Brake fluid for European vehicles can be confusing. Finding the correct specification can be ambiguous because some manufacturers give a part number instead of a specification in the service information or owner’s manual. The confusion gets even worse when you try to select a brake fluid from your parts supplier.

In theory, all fresh DOT 3, 4 and 5.1 brake fluids are compatible with each other. In practice, when brake fluids are mixed, the properties can change. Compatible and correct are two different things. New changes to vehicles have forced manufacturers to introduce low-viscosity formulations for DOT 4 and DOT 5.1 brake fluids.

Compatible and correct are two different things.

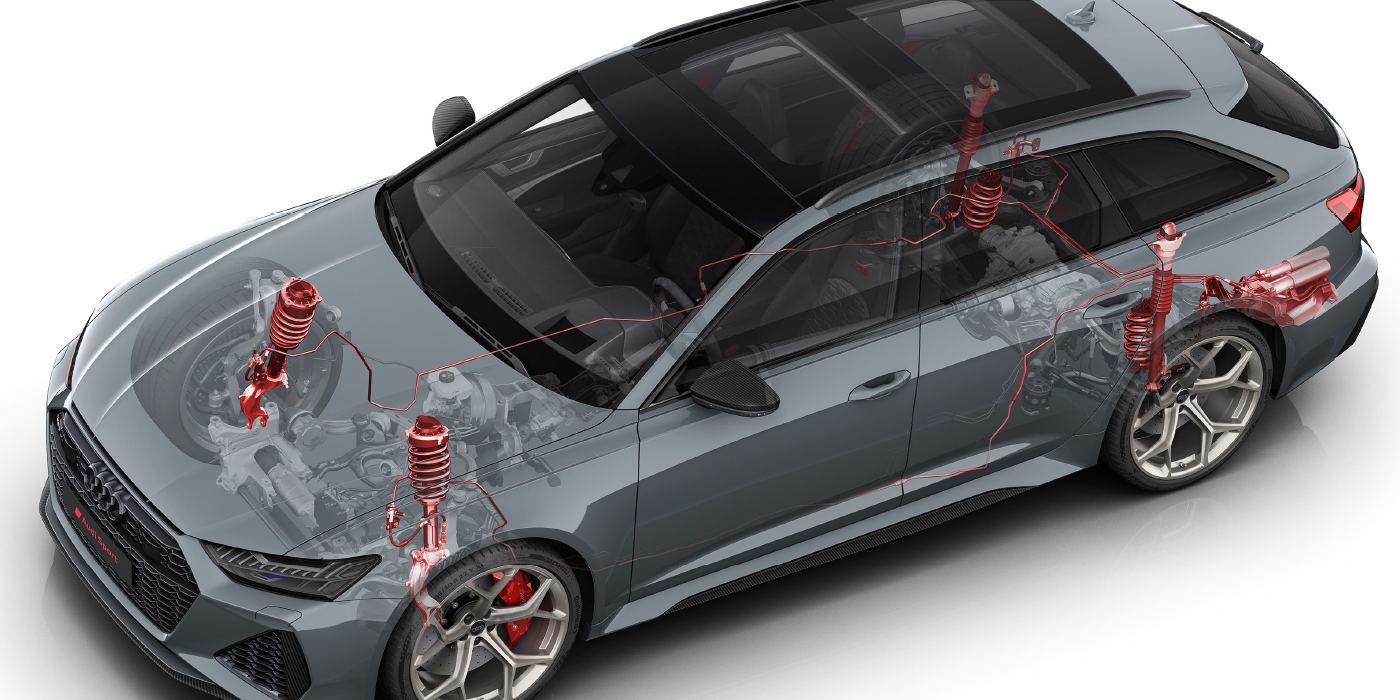

Brake systems are not getting hotter. Brake systems have seen the addition of ABS and stability control systems. Most of the changes to brake fluid are to optimize the pumps and valves inside the ABS hydraulic control unit (HCU).

The pressures inside the HCU can exceed 3,000 psi. If the brake fluid does not have the correct viscosity or kinematics, the fluid can cavitate when it is forced through the pump or valves. Cavitation produces tiny bubbles in the fluid. The small bubbles can alter the performance of the HCU.

The viscosity is controlled by the formulation of the base stock. The viscosity of the fluid is also changed by the percentage of water absorbed. The additive package also can control the viscosity and performance. The additive package is a mixture of anti-corrosion, anti-foaming and other secret chemicals that give the fluid the desired performance characteristics for operation in vehicles.

DOT Ratings

DOT stands for Department of Transportation. They set the standards for brake fluid. The two specifications they look at are the boiling point and the viscosity.

The boiling point is the temperature the brake fluid starts to boil or becomes a vapor. DOT specifies a dry and wet boiling point. The wet boiling point is measured when the fluid has 3% water content. To meet the DOT specification for boil point, DOT 3 fluid has a dry boiling point of 401º F and a wet boiling point of 284º F. As the DOT number increases, the boiling point increases. New standards for DOT 6 brake fluids were drafted during the pandemic.

Viscosity is measured by how the fluid spreads out over a surface in a measured amount of time. For brake fluid, the measurement is millimeter squared over a second or mm2/S. Viscosity has been the characteristic where brake fluid specifications have changed in the past two decades.

Two new brake fluid grades have been introduced to address the viscosity issue. DOT 4+ or Low Viscosity and DOT 5.1 ESP. Both of these fluids have a lower viscosity rating. When you compare DOT 4 to DOT 4+, the main difference is that the DOT+ has a viscosity of 750 mm2 instead of 1,800 mm2/s of regular DOT 4. The same is true for DOT 5.1 ESP that has a viscosity half of DOT 5.1.

The viscosity of the fluid is critical for the operation of the HCU. The kinematics of the fluid is highly dependent on the viscosity. If the viscosity of the brake fluid is changed, it could change the ABS performance and the corrections of the stability control system.

Compressibility is also a specification for brake fluid. Some very high-end racing synthetic DOT 4 and 5.1 synthetic fluids can give a better pedal, but it is so small of a difference that only the very, very, very best drivers can feel it.

Additive Packages

Due to contamination, heat and/or oxidation, additive package chemicals become depleted. When this happens, the pH of the fluid can change and the anti-foaming agents can stop working. Combined with high water content, the driver could experience brake fade. Some European manufacturers like BMW and Land Rover recommend an extended service life brake fluid. This fluid type has an improved additive package so that the replacement interval can be extended to three years.

Corrosion of the hydraulic components is a concern for OEMs. When the brake fluid additives degrade, the surfaces of the brake lines are first to start corroding. The increased pH causes copper to become suspended in the fluid. Copper comes from the copper brazing in the walls of the hard brake lines. Copper can be a problem for ABS and some valving but it is an indicator of the state of the brake fluid. The more copper that is present, the chances are greater that corrosion is happening in the system. When there is corrosion, it is a sign that the brake fluid’s anti-corrosion additives are depleted.

Flushing

With the difference in brake fluid viscosity, the old fluid must be removed from the master cylinder to the calipers. Replacing a vehicle’s brake fluid requires more tools and skills than a glass bottle and clear tubing. Old-school methods like the two-person or gravity bleeding techniques still work, but they are not efficient at replacing large volumes of brake fluid quickly. Machines and devices that can power- or pressure-bleed a system can make a fluid flush as efficient and profitable as possible.

Power and pressure bleeders are changing along with the systems they service. In the past, only 15-30 psi was required to pressure-bleed the system. But some new ABS modulators with electronic brake proportioning may need 50-60 psi to bleed or flush the system. If you can’t get your pressure bleeder to work under these conditions, look at the service information for the required equipment or pressure setting.

On their own, gravity, manual or power bleeding methods can’t thoroughly flush the volume of fluid in the ABS modulator. Inside the modulator, there might be as much as 5 ounces of dirty fluid after flushing. The only sure way to flush this fluid is to use a scan tool to actuate the valves in the hydraulic control unit. Be aware that the worst fluid is trapped in the ABS valves and passages due to their non-integral design.