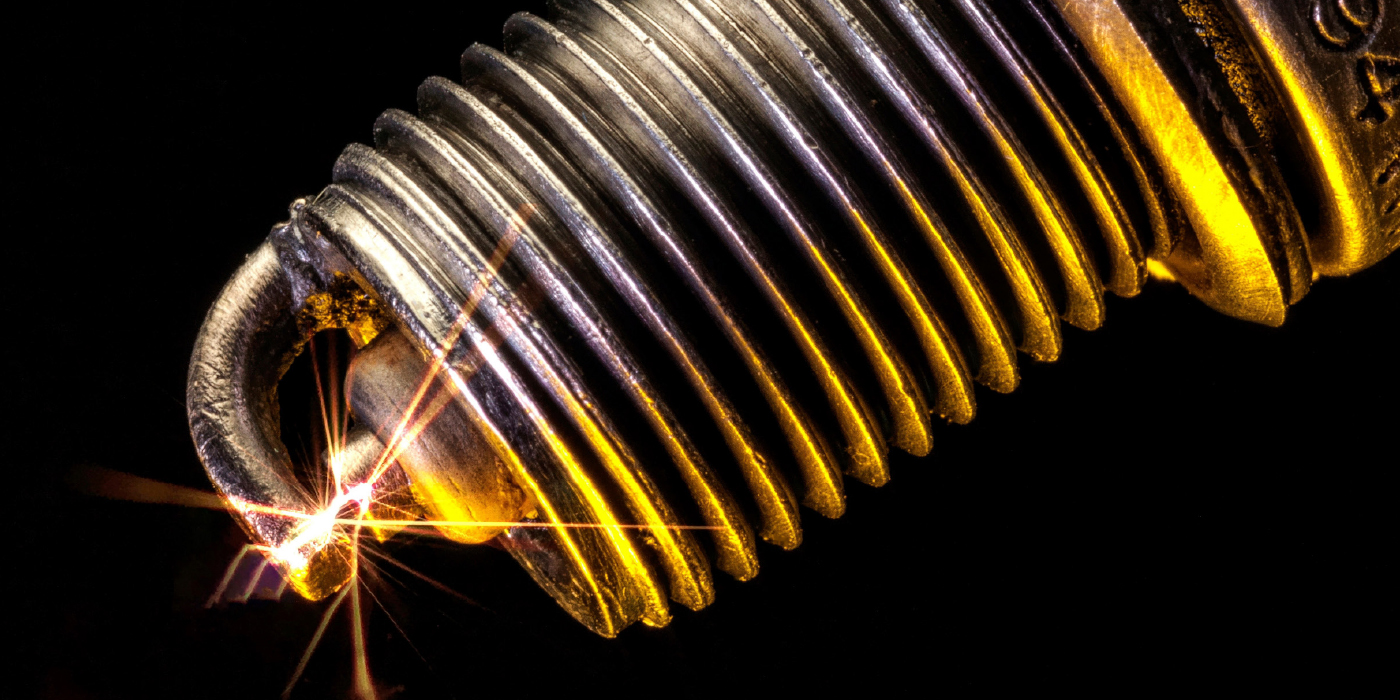

Head lift is a common occurrence in any internal combustion engine. In basic terms, head lift can be described as the lifting of the cylinder head from the deck surface of the block as pressure builds within the power cylinder.

While head lift occurs on all engines, the rate at which the head(s) lift is specific to engine architecture, operating conditions and the OE manufacturer’s performance/fuel economy requirements. As an Engineering and Manufacturing organization, Victor Reinz realizes the importance of understanding a given engines’ head lift characteristics prior to beginning the head gasket design process; this means identifying how and where the head lift occurs. As engine manufacturers strive to increase fuel economy, we’ve seen significant lightening of both block and head castings, this in an of itself can make sealing more challenging and is one of the main reasons why MLS cylinder head gasket technology has replaced composite style head gaskets.

In the sealing business, we talk a lot about recovery. Recovery is the gaskets’ ability to recover or maintain the contact pressure required to seal between head and block during periods of head lift.

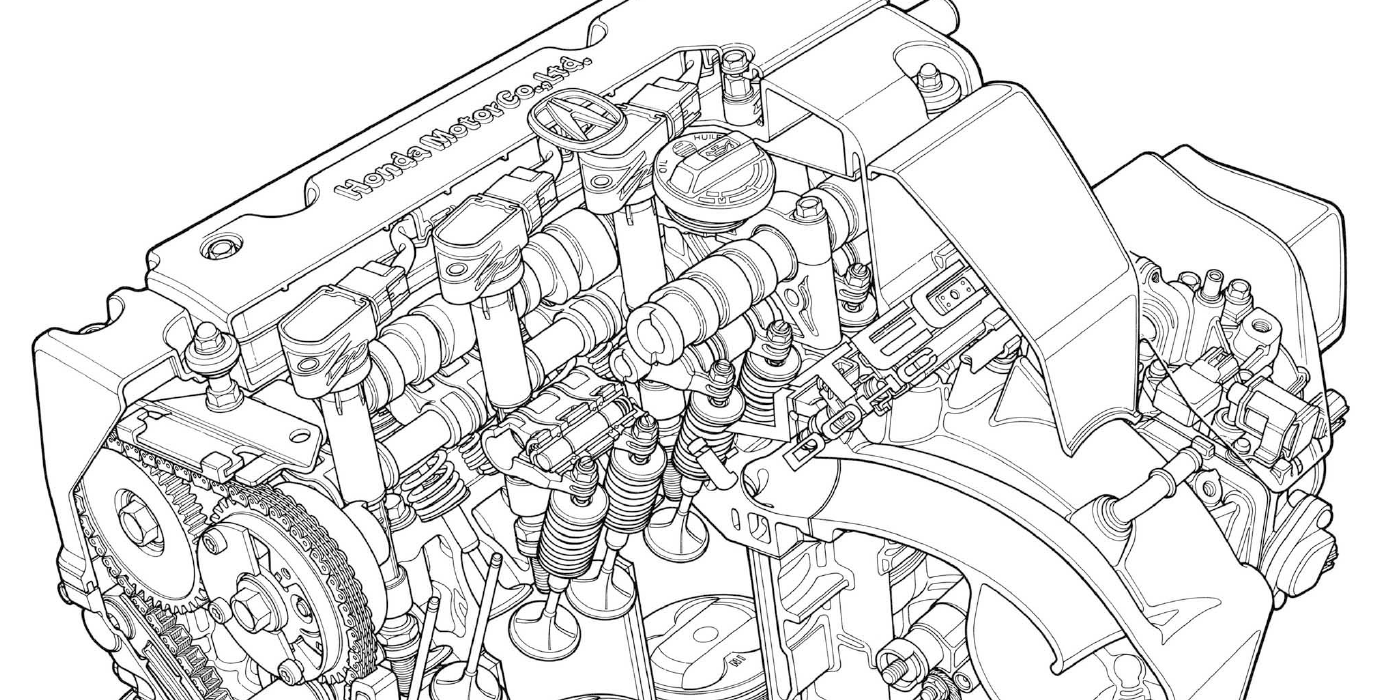

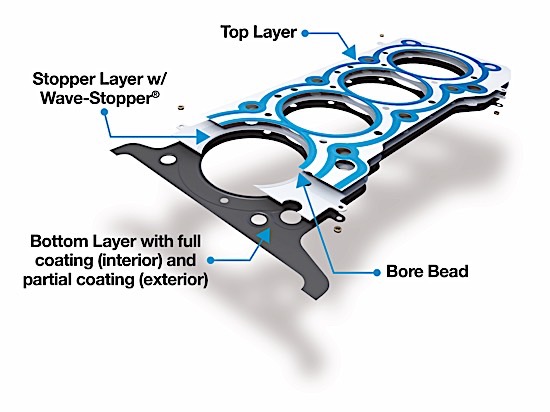

MLS head gaskets accomplish this through the use of emboss beads that surround each bore opening. As seen from edge-on, an emboss bead resembles a channel and has a distinct “U” shape and this “U” shape essentially creates a spring. A typical MLS head gasket features two or three “active” layers (those with an emboss feature) and one “shim” or flat layer. The active layers combine to form the aforementioned spring, and the shim layer provides the desired overall gasket thickness. It’s helpful to think of the stacked emboss beads as something resembling a valve spring. During periods of head lift the spring created by the emboss beads recovers the area lost to head lift. The cross-section of the emboss feature is critical to how that bead will perform its job and the design of the embossed bead and the materials used in its manufacture separate a functional part from a non-functional part.

Conversely, for an embossed bead to perform over the long term a technology designed to limit the compression of the bead must be present; this feature is referred to as a “stopper.” In this role, a stopper acts as a positive stop limiting the compression of the emboss bead. To this end, Dana/Victor Reinz uses a proprietary technology called WaveStopper.

While WaveStopper technology prevents the over-compression of the bore bead what sets it apart from other sealing technologies is its’ ability to vary the feature height around the combustion opening i.e. reducing the height at bolt hole locations (where load is present) and increasing the height between bolt spans (where load is lighter). The result is a much more evenly loaded combustion seal that creates less bore distortion and ultimately provides better piston ring seal. It’s a sealing technology that can actually enhance engine performance. These are qualities that are difficult to identify and measure at the installer level, which is why it’s critical to choose a gasket from a brand you trust.

This article was courtesy of Victor Reinz Gaskets from Dana Aftermarket. For more information on Victor Reinz gasket kits and sealing solutions, visit VictorReinz.us.