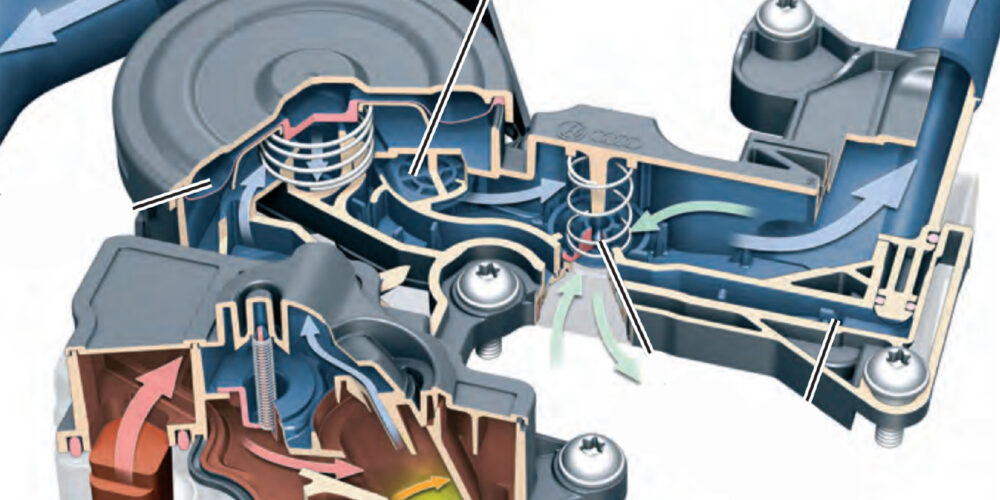

It has been a long drive to the lake. The driver carefully backs the trailer down the boat ramp. As the axles hit the water, the hot wheel bearing hubs hit the water. As the bearings’ heat is quenched by the lake water on the outside of the hub, the rapidly contracting air and lubricants inside the hub create a vacuum. If this vacuum can not be held by the seals, the hub will suck in water and contaminates.

While this is an extreme example, this type of contamination can happen to all bearings if the seals are not in good condition. It is clear to see, the most important part of bearings is the seal. If contaminates are able to work there way onto the contact surfaces, or the lubricant is expelled, the bearing will not last long.

Seal Materials

Wheel bearings, seals and hub units can operate at extreme temperatures. On front-wheel drive, and 4WD vehicles, the seals can be subjected to heat from the bearings and the brake system.

This harsh environment can stress the design of the seal, in addition to being very stressful on the physical materials used to make the seal.

Standard seals are often made of nitrile. Nitrile is an economical material that works well with most mineral greases and oils. It will last in temperatures as low as -40