It could be in a Land Rover, Mercedes or BMW, but chances are if you are a European specialist in the colder regions of the country, you will soon get a customer in complaining about a warning light or message saying there is a problem with their air ride suspension.

It is a common occurrence on the coldest days of the year or on a day with wide temperature variation, to get a customer call or visit complaining that they have a warning message on their dash telling them the air ride suspension system is malfunctioning or there is a fault. It is also a problem on higher-mileage vehicles.

The customer may say that the vehicle is not riding low and that they do not notice any other problems. But, in extreme cases, the customer may see a message that the vehicle is too low. By the time it gets to your shop or sits for more than 30 minutes, the air suspension could be working just fine, and the message could be gone, but a code for plausibility or a leak might be stored in the suspension module.

To the untrained technician, a winter air ride problem might lead down the path of assumption that there is a leak in the system. However, chances are there are no detectable leaks. These types of faults are usually set by parameters from the air ride module for a specific action to cause an expected result. Think of it as an EVAP system: an EVAP system can’t see an actual leak, but it can detect a leak with a pressure reading.

Codes might be correlated with the time it takes for the compressor to replenish the reservoir, or the time it takes to carry out a trim adjustment. If it takes too long, the control module will assume there is a problem and puts the vehicle into a safe mode to preserve the compressor and airbags.

While these observations by the system could be the result of a leak, these faults are more likely the result of a weak compressor, sensor or a problem with the solenoids controlling the system.

SENSORS

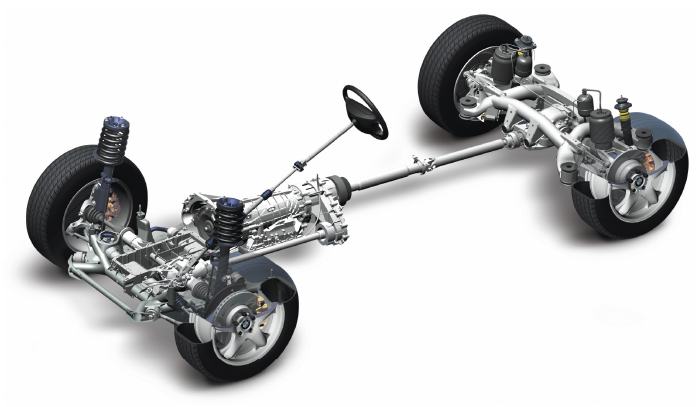

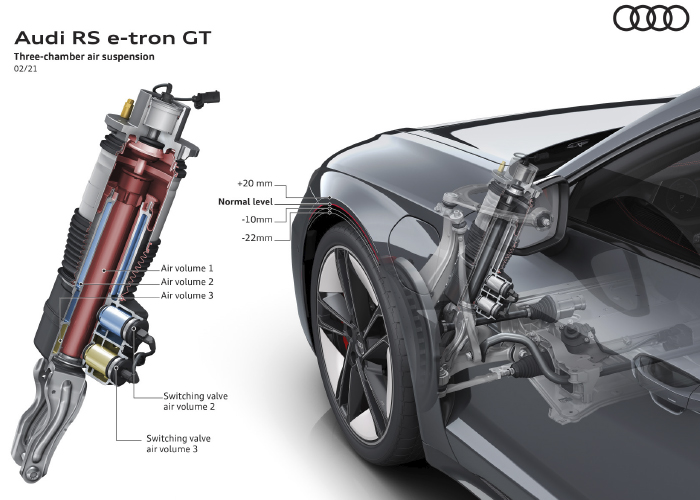

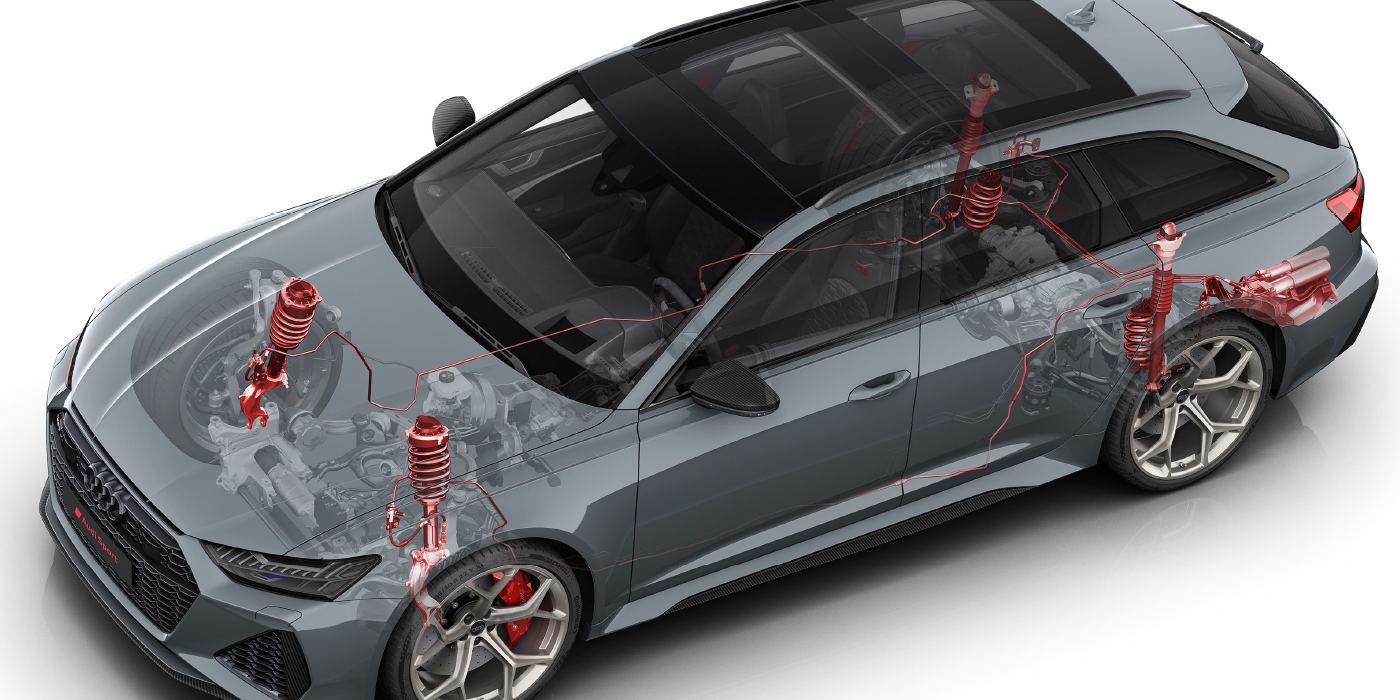

There are three types of sensor information a vehicle uses to trim the ride height and regulate the compressor: temperature; pressure; and ride height. Temperature is a significant parameter for air ride, such that air density and pressure can vary widely due to temperature. This is called Charles’s Law.

If a driver with an air ride suspension drives his vehicle home from work with an outside temperature of 32° F, and the brakes also heat the air in the bladders, the air’s volume in the bladder expands. If the driver parks the car overnight and wakes up to a 10° F morning, the air inside the bladder will have contracted and there will be less volume and pressure to support the vehicle. When he walks outside, the vehicle will be riding lower. Air temperature also impacts the reservoir. As the temperature decreases, the amount of air in the reservoir also decreases. This means there is less air to trim the vehicle.

Charles’s Law also applies to compressors. If air intake temperature is lower, the compressor can use denser air. In that case, the time to pressurize the reservoir should be reduced.

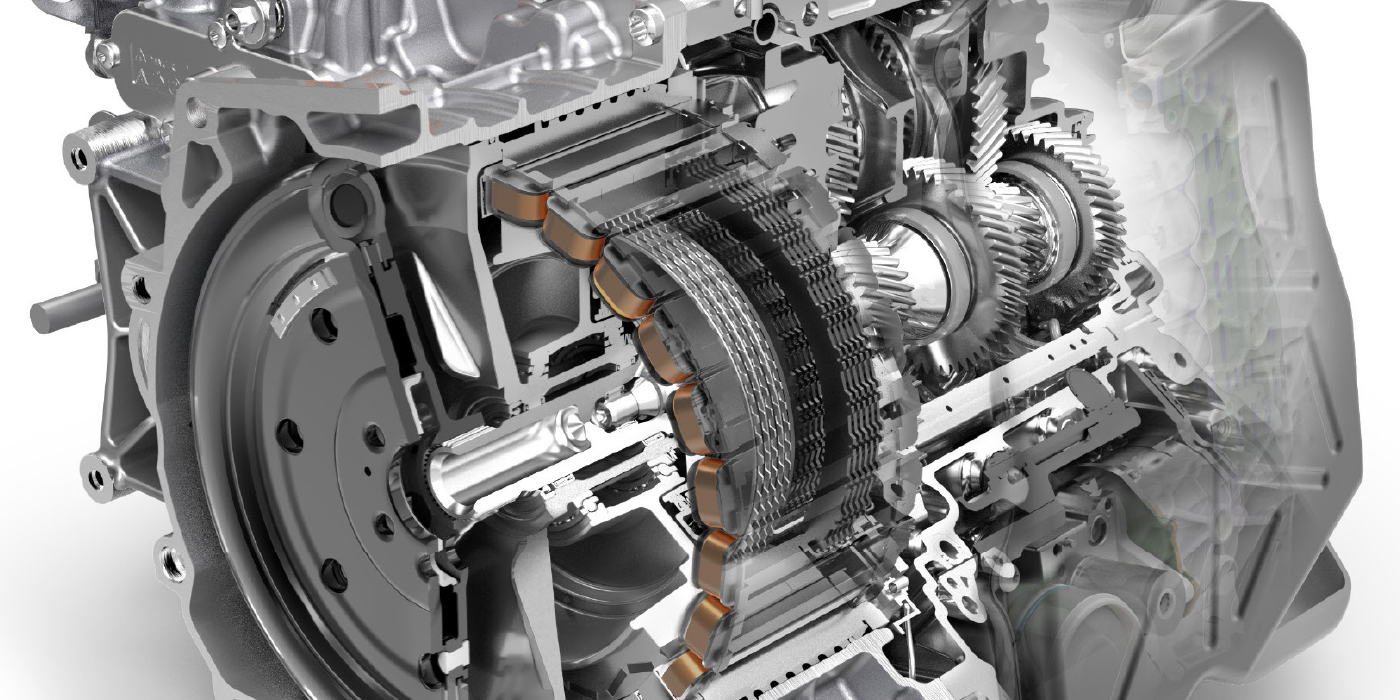

All air ride control modules regulate how long the compressor will run to keep temperatures inside at a safe range. The control module will look at ambient temperature and other factors to determine when, and how long, the compressor should run to generate the correct volume and pressure to fill the reservoir or trim the vehicle.

Outside, an ambient temperature sensor or the mass airflow sensor can determine temperature. Some systems will have a thermocouple connected to the compressor. Measuring air temperature is critical because it will determine how much time it will take the compressor to fill the air springs and reservoir.

Hall-effect sensors measure travel at the wheels. These sensors also measure the ride height of the vehicle. But, the data generated is used to determine if a correction or adjustment was effective by measuring the time it takes to adjust.

Pressure sensors are typically mounted in the reservoir, compressor or control block. Most systems will measure only the pressure at the reservoir. Pressure sensor input is used to determine compressor output and not the pressures that go to the wheels.

LEAK DETECTION

Most leaks will occur on the bellows of the air spring or the fitting for the air supply. Most air ride leaks fall into two categories — those that can be seen with the naked eye and those that need a little help to be seen. The soapy water method might work for some larger leaks, but there are special aerosol leak detector sprays that can make tiny leaks more visible by producing smaller bubbles with better surface tension.

Some techs have had luck using small, sensitive microphones to hear leaks coming from air ride components. But this method might not work in some noisy shop environments.

CODES

The codes for cold weather problems will typically include the words “replenish,” “reservoir,” “overheat,” “no pressure increase” or “timed out.” There are two main culprits for these codes: a weak compressor; or a leak in the system. It is possible that a sensor in the reservoir is faulty, but this is extremely rare.

Codes may require a scan tool that can communicate with the air ride system, and the codes may be proprietary to the make and model. Also, a good scan tool can perform bi-directional tests and calibrate the system.

One of the main operating parameters for the air ride system concerns controlling the temperature of the compressor. Modern systems are dry and do not use oil to lubricate the piston and bore. Therefore, excessive heat can destroy the piston seal and bore.