When a CV axle fails, it is for a reason. Rarely will an axle fail because it is just worn out. The failure of an axle can usually be traced to torn boot, alignment issue or a problem with components attached to the axle.

Axle Alignment

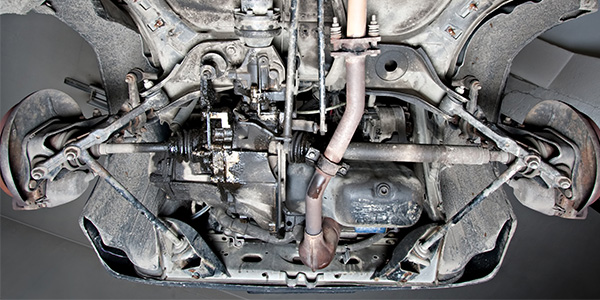

If the subframe or mounts are misaligned, the geometry of the inner and outer joints will be altered. For outer joints, the CV joint may exceed the maximum angle of operation. For inner plunge joints, the axle could bottom out. If the replacement axle is close, but not exactly made to the correct specifications, the misalignment of the axles can be even more compounded. Also, some manufacturers like Honda have a centering procedure that involves loosening the motor mounts and installing the axles.

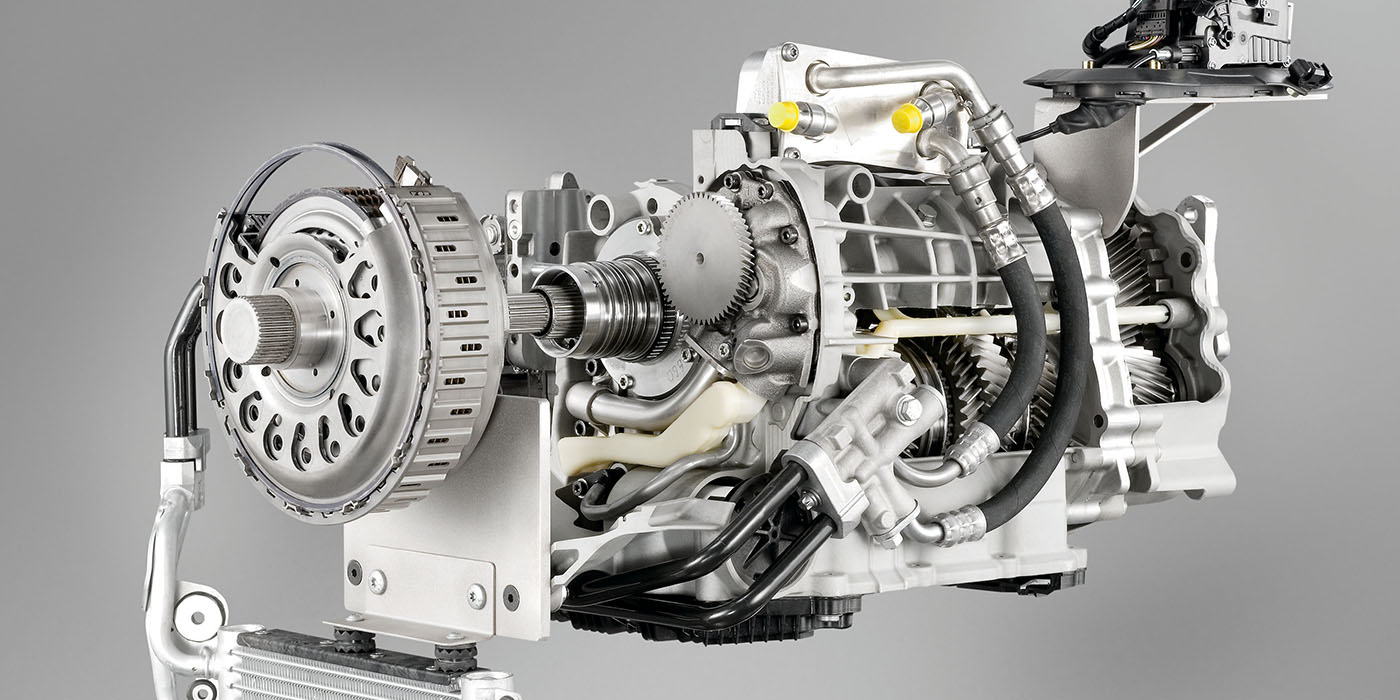

Wrong Axle, Bad Engineering

Sometimes, issues with a wrong axle can occur if it is not ordered correctly. On some vehicles, the difference between the manual and automatic transmission axle length might be a few millimeters, but it might cause a plunge joint to be too shallow or too deep. If the axle is too long, it can cause the CV or plunge joint to bottom out and damage the surfaces of the balls, bearings and races. If it’s too short, the axle could pull out of the plunge joint under certain conditions.

Vehicle Alignment

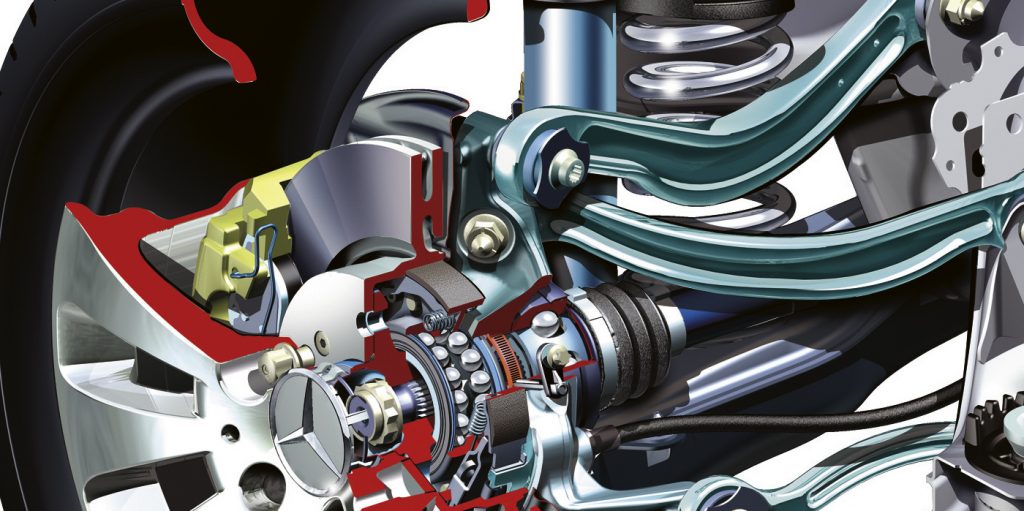

If a CV joint has failed, look at the condition of the suspension. Bent components can cause the range of motion of the joint to change. On the alignment rack, make sure you check the included angle to see if a steering arm or strut rod is bent.

Seals

One mistake made by technicians when installing a new axle or driveshaft is not addressing the seals in the transmission, differential or transfer case.

Most seals ride on a shaft and typically have a lip and a spring that holds the lip to the axle. When a seal is installed, take your time installing the axle. Splines can damage the seal and cause leaks.

The area on the shaft where the seal and bearings make contact is the most important. It must be free of any rust and imperfections. Use only a fine-grade emery paper to clean the axle shaft between the flange and the worn area.

If the surface is grooved or damaged, the axle can be repaired with a sleeve, on some applications. If not, the axle should be replaced. Make sure the seal is installed in the correct position.

Breathers

Make sure the breathers are not clogged. The breather acts as a PCV valve to keep pressures within a certain range so the seals can work their best as the differential heats and cools. If a breather is clogged, the temperature will increase pressure in the axle. As the transmission cools, negative pressure could build up behind the seal. These changes in pressure will cause the lips of the seals to deform and leak.

It’s important to note that any leak on an axle should be taken seriously. Ignoring a leak can be very expensive and destroy the bearings, brakes and differential.

Replacing Just the Boot

You might think you caught a CV joint before all of the grease was ejected, but the damage might have already occurred. CV joint housings are typically forged from iron billets. After the joint is machined, induction heat-treating is used to harden wear surfaces. Wear in a CV joint usually occurs on the cage, gear and cup. This wear is typically caused by a loss of lubrication due to a boot failure, or debris in the joint. Once heat-treated surfaces are damaged, they usually cannot be restored.

Clicking or Popping

If a customer reports clicking or popping after an axle or wheel bearing has been replaced, it could be coming from the shoulder area of the axle where it meets the inner race of the bearing. Nissan, BMW, and Mercedes-Benz have issued TSBs on how to cure noise that happens under cornering, braking and acceleration.

The solution for all of the OEMs is to apply a light coating of moly lubricant to the shoulder of the CV axle. The other cause for the clicking and popping noise cited in the TSBs was a failure to follow the correct procedures when tightening the axle nut.