If you work on European cars, you already know these customers care about performance. Expensive European vehicles are often considered to be “premium” or “luxury” because their systems are more complex than other brands. Audi, Volkswagen, Porsche, BMW and others have helped imports carve out a 46% share of vehicles in operation on U.S. roads today, and that number continues to climb. These brands are also starting to pick up traction in the SUV segment as well. Why? Because Americans love luxury and high-performance vehicles, and the European brands deliver these attributes in spades.

European vehicle brands are early adopters of new technology, which has been the case with ABS and Electronic Fuel Injection, and many more technologies. Regulations in the EU have also mandated that parts and components meet strict standards. For example, the ECE R90 regulation was implemented in 1990 to ensure that replacement brake linings are made to meet specific performance criteria. This regulation expanded in 2014 to include brake rotors and drums, where tests are set up to quantify the performance of the various brands on the market. The U.S. does not currently have any standards that apply to brake rotors or pads.

Replacement parts in the EU are evaluated for performance with tests that include frictional properties, brake load strength and thermal fatigue. The part must meet minimum requirements in all three of these areas to be certified. Parts must also meet dimensional compliance for part geometry and balance. None of these are required in the U.S., as we rely on the market to decide and quality manufacturers to lead the way.

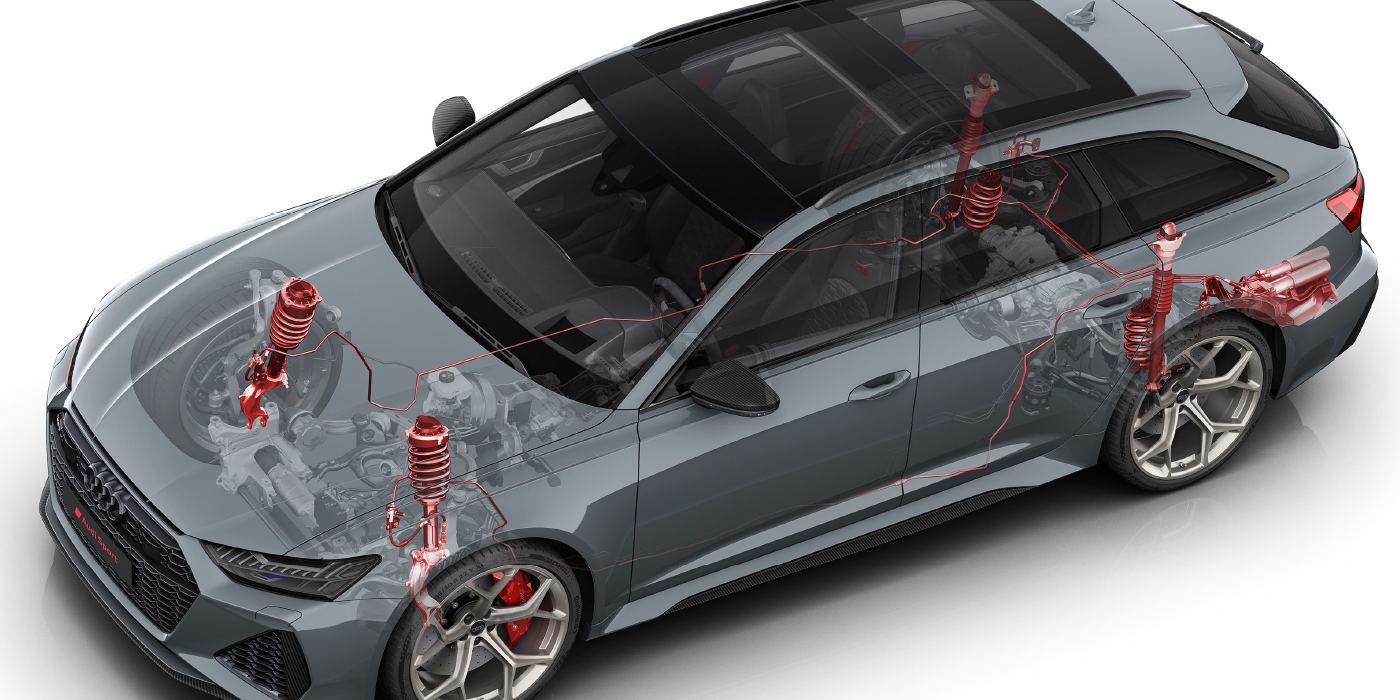

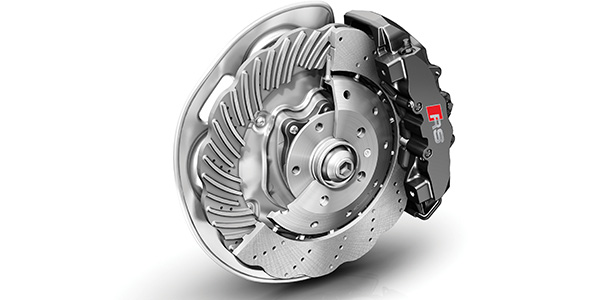

Brake rotor finish is an important topic when it comes to European vehicles because they are more sensitive to poor (rough) surface finishes and irregularities in the casting process. It is not uncommon for a premium European vehicle to use high-performance brake systems that include multi-piston fixed calipers and larger rotors made of high-quality materials, and even some exotic materials in the case of carbon brake systems.

Don’t cut corners on high-performance/luxury imports because your customer spent big bucks to get the vehicle, and he or she expects the replacement brakes to perform to OE levels or better. Turning rotors may be acceptable for many other cars, but it is generally not a good idea with a premium European import since these brake systems generate more heat than other vehicles due to their massive rotors and pads. The stopping power is more on the level with a racecar than a production car for some of the ultra-high-performance/luxury models. A BMW X5 M, for example, has large 15-inch brake disc that fits inside a 20-inch wheel. A Lamborghini URUS has a massive 17-inch front disc and 14.5-inch rear disc. The more exotic and expensive the car, you can expect the brake rotor to follow suit.

Besides being bigger, rotors for high-performance vehicles are more likely to be drilled, slotted and treated with a coating. Be sure your shop knows how to handle them. The coating should not be machined off or treated. Slotted and channeled rotors are often direction-specific. Make sure you’re installing the rotor in the correct orientation; otherwise, you may turn the cooling channels into heating vanes. The general rule of thumb is to place the angle of the slots toward the front like a paddle, so the outer part of the slot touches the brake pad before the inner slot. There are also several types of coatings, and some are to resist rust. If rust sets in it may clog the cooling channels and create high spots from the added heat.

Some manufacturers of performance rotors offer cryogenically treated, slotted rotors to improve durability. Although the naked eye can’t see the treatment, rotors that are cryogenically treated show improvements in longevity.

Rotor materials can also affect noise. For example, some cast-iron grades are quieter than others, which is why composite rotors were introduced. Composite rotors are lightweight and can also be quieter when the right grade of cast iron is used. Keep in mind that a solid cast rotor can change the brake system harmonics and may increase the risk of brake noise. Also, some low-priced rotors may use a lower grade of cast iron that is noisier than the OE and premium rotors.

Whether or not your customer uses his or her vehicle for spirited, performance driving, you can rest assured that they want the full use of the vehicle’s braking ability if, or when, they need it. Your European import customers expect the best anyway, so do your shop a favor and buy the best brake parts you can get.