Incorrect readings can be avoided.

With the recent changing of seasons, it is possible to see a 20- to 30-degree temperature change from when the car is parked in the evening and driven again in the morning. Some customers may say they think the ambient temperature is not reading accurately. To achieve a "smoothing" effect of the displayed outside ambient temperature, the value shown does not instantaneously follow the temperature sensor measurement.

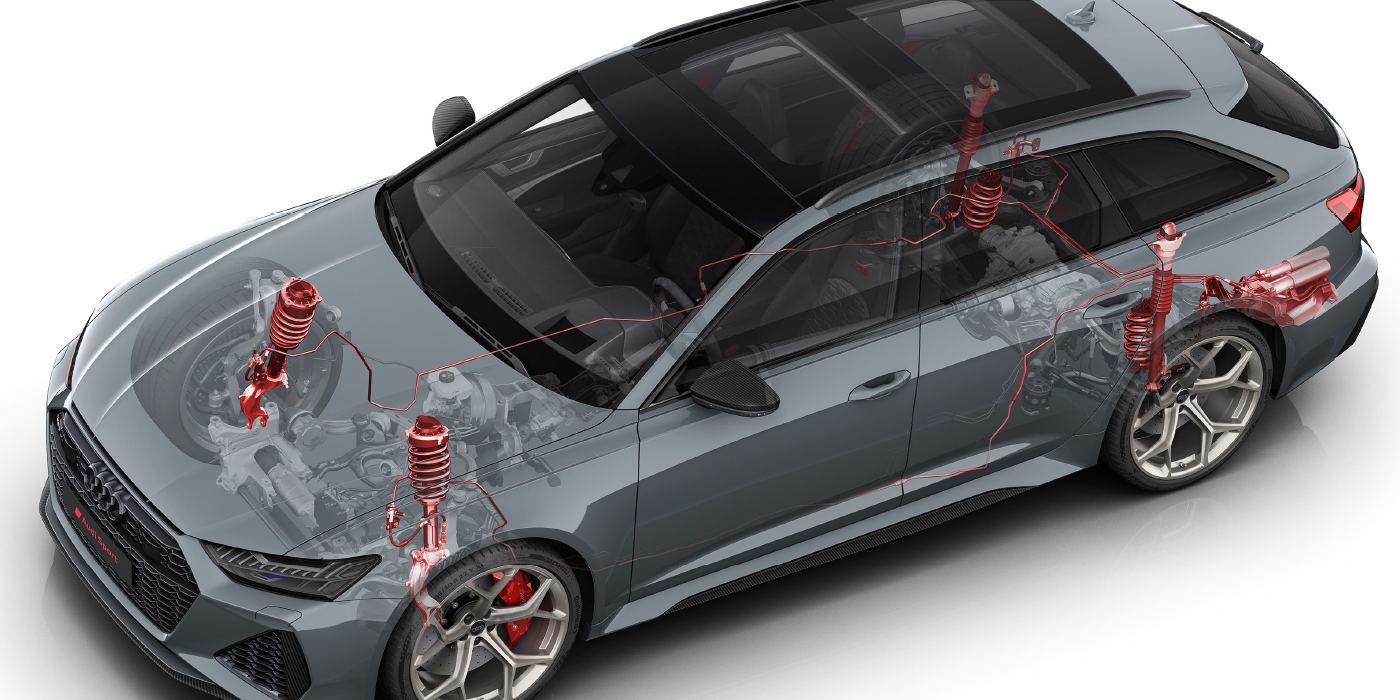

The system provides great ride & handling, but it can be complicated to service if you do not have the right training.

Technical Service Bulletins can be valuable in helping solve vehicle problems. But sometimes, it takes multiple TSBs to find a pattern failure or the “root cause” of a problem. In the case of the Audi/VW 2.0L Fuel Stratified Injection (FSI) engine introduced in 2006, three problems related to engine carbon and fuel issues are connected

Taking a guess can get very pricey if you can’t return the part.

Models: F97 X3 M F98 X4 M G01 X3 G02 X4 G20 3-Series SITUATION After replacing the microfilter during a previous service, the customer notices that the ventilation system airflow rate is noticeably less. This leads to perceived lower cooling power. The customer may also notice that external odors enter the vehicle. Related Articles –

Let’s take a closer look at this unique water pump, how to replace it efficiently and what other components should be replaced along with it.

The key to servicing these systems is proper information and understanding precisely how these systems operate.

BMW has offered Tire Pressure Monitoring Systems (TPMS) for more than 20 years. These early indirect and direct systems were implemented not to meet the 2007 government mandate but to inform the driver when an expensive Michelin or Bridgestone run-flat tire was deflating. Some 2002 and 2003 models have an indirect system called Flat Tire

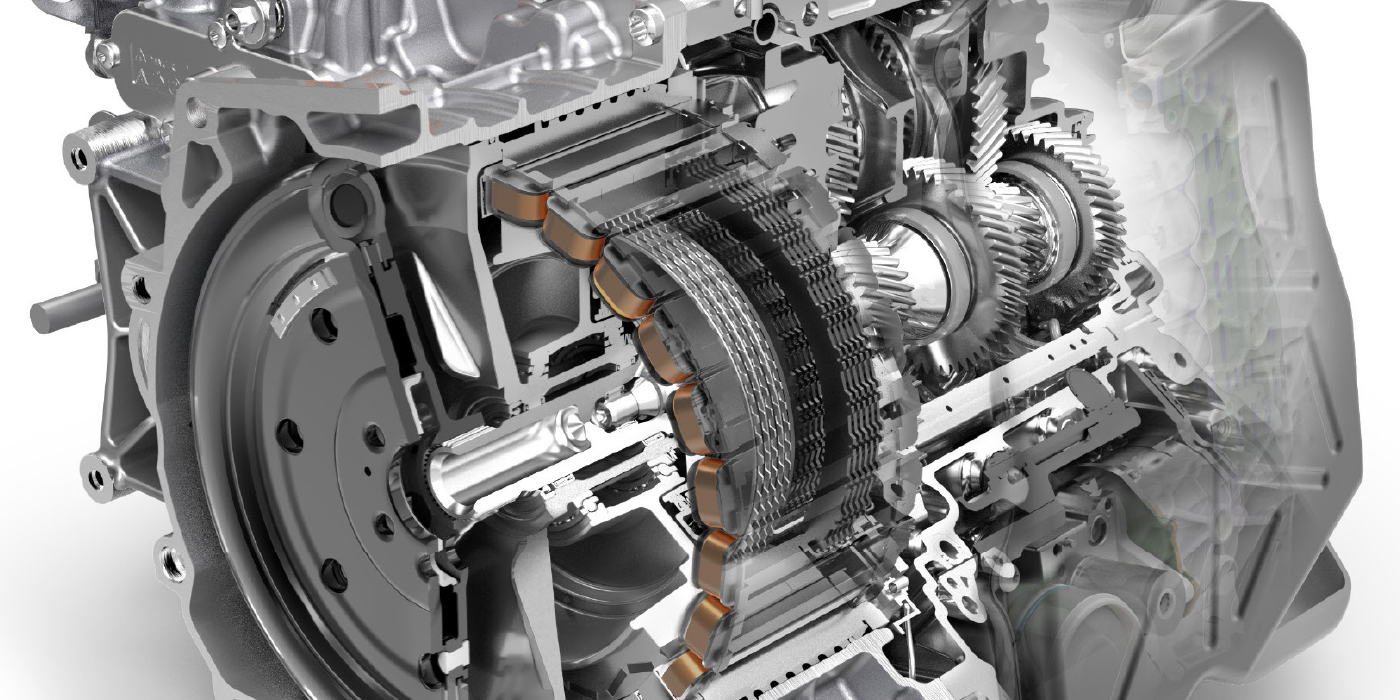

A DSG transmission is lighter than a comparable automatic with the same number of speeds.