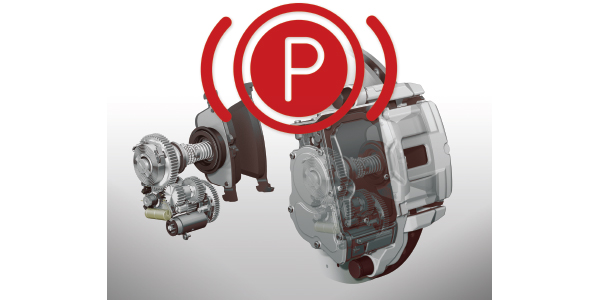

The majority of Volkswagen vehicles sold in the past five years have electronic parking brakes. Most customers don’t even realize that the vehicle has an electronic parking brake. The system engages and disengages the parking brake automatically on most vehicles. But, when the system fails and turns on the light or has a warning in the driver information center the customer will notice.

If you are doing a brake job on a vehicle with an electronic parking brake, you will need a scan tool with the proper software for the parking brake system to retract the calipers, adjust and perform diagnostics. There are no shortcuts on YouTube. You can find videos that involve removing the electric motor, jumping connectors and disassembling the parking brake mechanism. But, these methods are very risky and can damage the vehicle and kill productivity. Unapproved methods will set malfunction codes, and the worst-case scenario is that you could damage the unit.

The VW system that was installed on a number of platforms starting in 2004 is an example of a system that equires a scan tool to replace the rear brake pads.

The system has stepper motors on the back of the caliper that actuate the piston. The motor can removed from the caliper though the ignition should be switched off for at least 30 seconds before removing the connector.

The motor is sealed to the caliper with an o-ring around the spindle. The condition of this o-ring is critical for the life of the motor and should be lightly lubricated with brake fluid. If the o-ring fails, water and debris will be one step closer to the motor gears.

The spindle on the caliper can be rocked slightly with a torx bit so the motor seats in the spindle. Don’t force the motor assembly onto the caliper, because damage to the housing can occur.

On recent platforms, VW have outfitted the motors with a sensor that can measure brake pad wear and adjust the pads for the least amount of drag. During this adjustment on some vehicles, the pad thickness is calculated.

Diagnostics

Inspecting the caliper, hardware and motors may not give you a complete picture of what is happening with these systems. Having access to a scan tool can reduce diagnostic time.

The OEMs have built-in bi-directional protocols to retract the parking brake so the pads can be replaced. A dedicated brake tool or enhanced scan tool is able to command these protocols and interrogate the module for codes and faults.

The Electronic Parking Brake Module (EPBM) is the module on the CAN bus of most vehicles equipped with this system. Any missing data for vehicle speed, gear position or brake pedal input will cause a problem with the system.

Some systems use information from the electric parking brake to track shoe and pad wear. The system will count the number of turns the actuator makes or the position of the stepper motor to determine the thickness of the friction material.

Another diagnostic approach is to check the operations section of the parking brake system in the vehicle’s service information. Some systems will use the parking brake for hill holding if an incline is detected, and some systems have an “Auto Hold” or “Roll-Away Prevention” function that will prevent the vehicle from rolling forward at stops. This system uses the valves in the ABS modulator to hold pressure at the calipers.

If you do find yourself working on a vehicle where the electronic parking brake will not disengage, the first thing to do is look at the basics. Some systems require that the doors are shut and the brake pedal is depressed. Some models may even require the seat belt to be buckled. Simple items like a defective brake pedal or door switch may hinder operation. Also, in some cases, the button may be defective. On some vehicles, the operation of the switch can be verified with a scan tool.