Applicability: 2003-’08 Corolla and Matrix models

Some customers may experience a front brake rattling noise when the car is traveling over bumps. Updated front disc brake cylinder (caliper) mountings and disc brake pad support plates are available to eliminate this condition.

Repair Procedure:

1. Conduct a road test to verify the noise condition; front brake rattle noise will occur when the front tire runs over a depression in the road.

2. Remove and replace the front disc brake pad support plates (two per each caliper).

Note: The procedures listed below are for one side and should be used for both the right and left sides.

a. Remove the front wheel.

b. Remove the caliper by holding the front disc brake slide pin and removing the two bolts.

c. Remove the two front brake pads from the front disc brake cylinder mounting.

d. Remove the anti-squeal shims and the pad wear indicator plates from each pad.

e. Remove the two front disc brake pad support plates from the cylinder mounting.

f. Remove the front disc brake cylinder mounting by removing the two bolts.

g. Install the new disc brake cylinder mounting with the two bolts. Torque: 107 Nm 79 ft.-lbf.

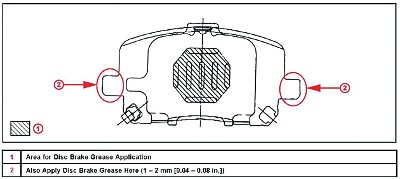

h. Install the two new disc brake pad support plates. Apply disc brake grease to the back of the brake pad support plate.

i. Install the front anti-squeal shims. Apply disc brake grease to the anti-squeal shims. See Fig. 1, 1.

Note:

– When replacing worn pads, the anti-squeal shims must be replaced together with the pads.

– Make sure to install the shims in the correct positions and directions.

– Apply a thin layer of disc brake grease to the area that contacts the anti-squeal shim.

– Disc brake grease can come out slightly from the area where the anti-squeal shim is installed. Be sure to wipe off any excessive grease to avoid pad contamination.

– Make sure that disc brake grease is not applied onto the lining surface.

– Install the anti-squeal shims and the pad wear indicators to each pad. Make sure to install the pad wear indicators in the correct positions and directions.

j. Install the two front brake pads with anti-squeal shims to the disc brake cylinder mounting.

Apply a small amount of the disc brake grease (1-2 mm [0.04-0.08 in.] thick) to the areas shown in Fig. 1.

Note: Do not apply grease to the friction surfaces of the brake pads or the disc rotor.

k. Install the caliper with the two bolts.

Torque: 34 Nm (25 ft.-lbf.)

l. Install the front wheel. Torque: 103 Nm (76 ft.-lbf.).

3. Road-test the vehicle to confirm the front brake rattle noise is no longer present.

Courtesy of ALLDATA.