Gasoline direct injection has become a widely recognized term in today’s automotive space. Port fuel-injection systems inject fuel at lower pressures before the combustion chamber, typically spraying fuel directly onto the intake valves. Direct-injection systems inject fuel directly into the combustion chamber and at a much higher pressure when compared to port injection.

Injecting fuel at higher pressures allows manufacturers to control combustion more accurately, boost power and fuel economy. As emissions and fuel economy standards grow tighter, automakers have had to come up with more innovative ways to conform to them. Now, direct injection has all but replaced port fuel injection in late-model vehicles.

Direct injection has been a huge jump forward for the industry. You may think that it is rather new technology, but it might surprise you to hear how long it has been around.

Where it All Started

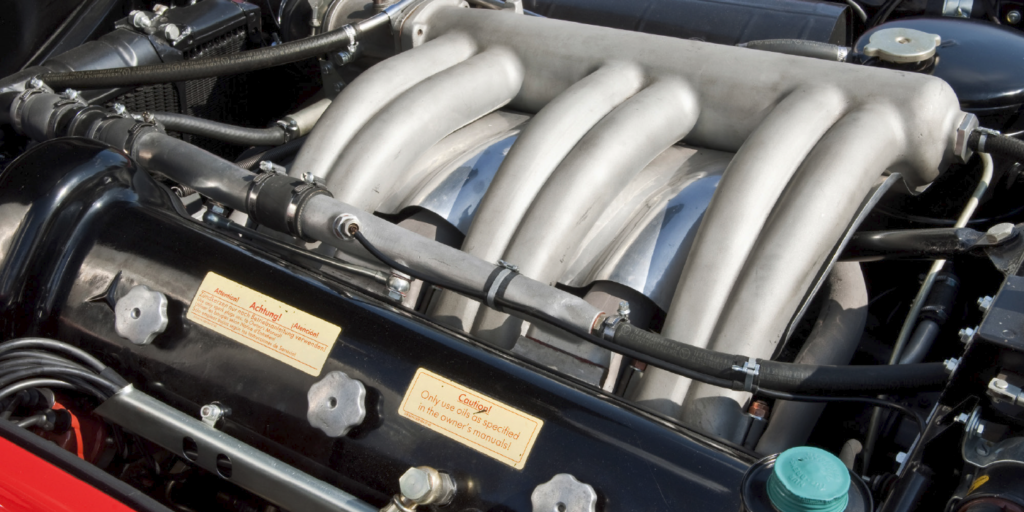

In 1954, Mercedes-Benz released the now legendary 1954 300 SL “Gullwing” coupe. This stunning vehicle is easily recognizable thanks to its unique doors, which pivot from the roof and open upward. The 300 SL featured the world’s first gasoline direct-injected engine, which was derived from the Benz-designed Messerschmitt aircraft engine in WWII.

Despite this innovation, direct injection didn’t seem to find a foothold in the automotive industry. Carburetors were cheaper and easier to produce, and this would remain true for decades.

Second Wind

Fast forward 50 years and you’ll find direct injection still in its infancy. A few manufacturers were beginning to develop direct injection or offer it in their vehicles, but in small numbers. Mercedes-Benz then released a new 1.8L, four-cylinder engine in 2002 with a new generation of direct fuel injection called CGI (Stratified Charge Gasoline Injection).

This 168 hp engine was available in the CLK and C-Class, but it was not a standout engine. It cut back on emissions and offered better fuel economy, just as expected, but it wasn’t particularly fast, pleasant to listen to and didn’t deliver smoother power compared with similar engines. Sadly, this engine fell into obscurity.

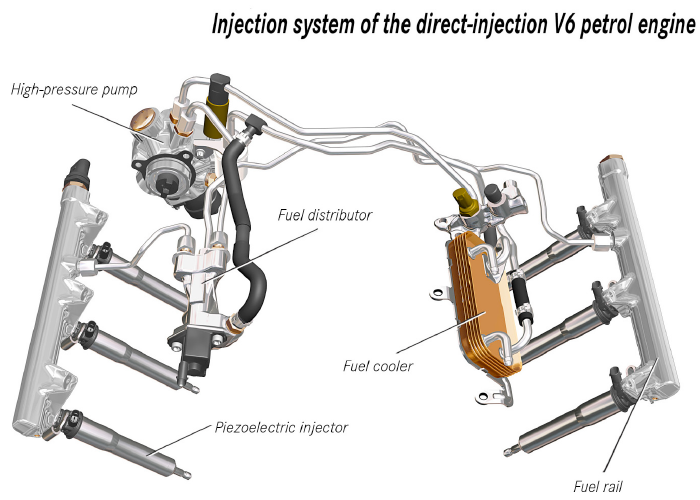

Both of those engines were way ahead of their time, but we know that Mercedes-Benz is never done pioneering and pushing the envelope. They saw great potential with direct injection and continued to invest in the technology. After an intensive development process, they released the world’s first gasoline engine with piezoelectric gasoline direct injection in the 2006 CLS 350 CGI. This revolutionary engine boasted 10-15% fuel consumption improvements over its existing V6 port fuel-injected engines, as well as an increase of around 20 hp and 4% more torque.

According to Mercedes-Benz at the time, “this new system will form the basis for future engine development work in this output class.” This focus had an impact on the entire auto industry.

Piezoelectric

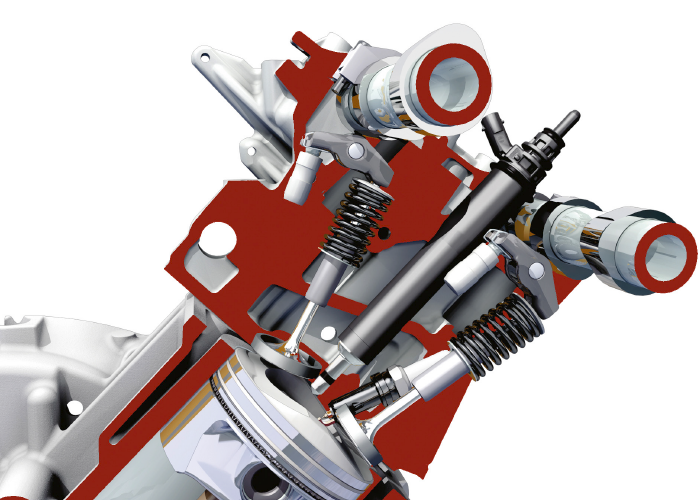

Piezoelectric injectors were typically found on common rail diesel engines, but they’re proving to be quite effective in gasoline direct-injection systems as well.

Piezoelectric injectors can open and close much faster than conventional units. This means that these injectors can more precisely meter the amount of fuel that is being injected into the combustion chamber. The ECU can precisely control the injector-open time and, therefore, the amount of fuel that is injected into the combustion chamber. This all leads to optimized combustion efficiency, maximized power and fuel economy.

The injectors can inject fuel several times during a single combustion cycle if the engine is under heavy load, or they can be only partially opened to limit fuel used during low-load situations such as coasting to a stop.

What Changed?

Thanks to the CLS CGI, gasoline direct injection (GDI) was offered in the U.S. market with very limited production in model year 2006. Fast forward a little over a decade and that number has risen significantly. According to the 2019 EPA Automotive Trends Report, 51% of the U.S. fleet had direct-injection engines.

What’s Next?

It’s safe to assume that the number of vehicles equipped with systems like direct injection will continue to rise year to year.

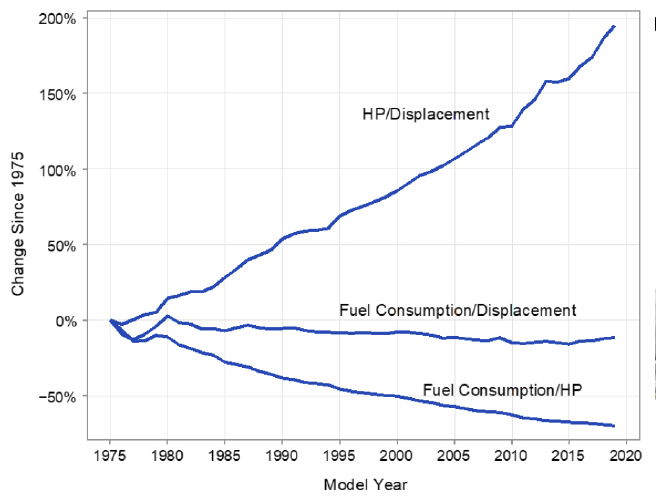

The graph from that same EPA Trends Report takes a closer look at two factors that illustrate how much automotive engines have evolved over the last 45 years: the amount of fuel consumed compared to the overall size of the engine (Fuel Consumption/Displacement); and the amount of fuel consumed relative to the amount of power produced by an engine (Fuel Consumption/HP).

It’s clear to see that engines are making more horsepower with less fuel than ever before. It makes you wonder, what will vehicle manufacturers come up with next to meet the needs of the future?