By Dennis Shortino, ALLDATA editor and Jeff Webster, ALLDATA technical writer.

Some Prius owners may complain of a metallic knock or clunk noise from the engine bay heard only while driving over speed bumps or rough road conditions. The engine mount assembly has been improved to prevent this condition. Follow the repair procedure in this tech tip to correct the condition.

Applicable Models:

This TSB applies to 2004-’08 Prius vehicles produced before the production change effective VINs shown.

PLANT PRODUCTION CHANGE EFFECTIVE VIN*

Tsutsumi JTDKB2#U#83430579

Toyota Auto Body JTDKB2#U#87793270

*Underlined number in VIN (11th digit) represents assembly plant line code.

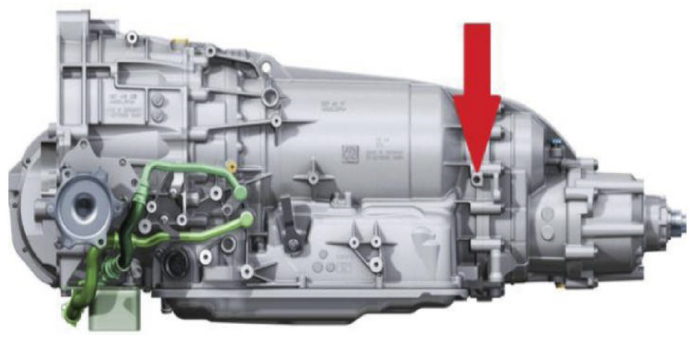

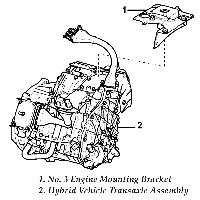

Note: The affected mount is attached to the hybrid transaxle. The part name in this service bulletin is “Engine Mounting Insulator LH” (left-hand). This is also referred to as “No. 3 Engine Mounting Bracket.”

Repair Procedure:

After verifying that the “knock” noise is coming from the area near the hybrid transaxle, replace the engine mounting insulator LH with a new part.

1. Remove the inverter w/converter assembly. Note: Do not replace the inverter.

2. Support the hybrid transaxle assembly by using a transmission jack.

3. Remove and replace the engine mounting insulator LH (No. 3 Engine Mounting Bracket) (see Fig. 1).

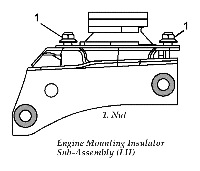

a. Remove the engine mounting insulator sub-assembly LH from the vehicle.

b. Remove the two nuts from the engine mounting insulator sub-assembly LH (see Fig. 2).

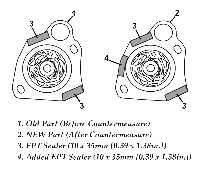

c. Replace the engine mounting insulator LH with the new part (P/N 12372-21111) (see Fig. 3).

d. Tighten the two nuts. Torque: 47 ft.-lb. (64 Nm).

e. Attach the engine mounting insulator sub-assembly LH on the vehicle. Torque: 59 ft.-lb. (80 Nm).

4. Install the inverter w/converter assembly.

5. Road-test to verify proper operation of the vehicle.

Courtesy of ALLDATA.