Along with a replica of Leonardo Da Vinci’s masterpiece "The Mona Lisa" created from 65 pieces of toast, shrunken heads and tornados capable of driving a piece of straw into a tree, this Cadillac tech tip qualifies as one of those strange "Believe It Or Not" stories.

Along with a replica of Leonardo Da Vinci’s masterpiece "The Mona Lisa" created from 65 pieces of toast, shrunken heads and tornados capable of driving a piece of straw into a tree, this Cadillac tech tip qualifies as one of those strange "Believe It Or Not" stories.

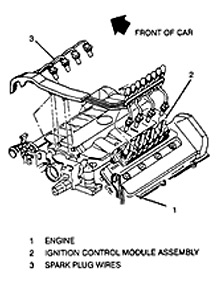

Owners of mid-90s Cadillac Eldorados, Sevilles and Concourses, equipped with the 4.6-Liter Northstar engine, may experience a heater blower motor failure after performing service to the right bank of spark plugs, spark plug wires or ignition control modules.

I told you this was strange. The reason for this malady may be that the spark plug wires are routed incorrectly and lying near or contacting the blower motor housing. Under normal operating conditions, low frequency voltage discharges emitting from the right (rear) bank of spark plug wires may affect blower motor operation and/or cause the blower motor to fail.

The repair is simple. When servicing right (rear) bank engine ignition components, exercise caution when installing the spark plug wires. Spark plug wires must be routed away from the firewall mounted blower motor. Refer to the illustration for proper routing. By the way, blower motor operation will not affect the ignition system…"Believe It Or Not."

Written by ALLDATA Technical Editor, Rich Diegle. Rich is an Advanced Engine Performance Certified and ASE Master Technician with an Associate of Arts degree in automotive technology and 23 years of dealership and independent shop experience.

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.