Engines with the automatic start-stop feature have become a de facto standard in passenger cars and light-duty vehicles. One unfortunate consequence of frequent start-stops is that the tribological stress upon some critical engine components, such as bearings, increases significantly. While starting the engine corresponds to only an infinitesimal fraction of the engine service life, it accounts for up to 75% of engine wear and wear-related failures. With start-stop technology, the number of engine starts gets a tenfold increase on average, and is even higher in the city traffic.

At the same time, the majority of present-day crankcase lubricant specifications largely overlook the impact of start-stop technology on engine health. As a result, the lifetime of bearings in engines with automatic start-stop engineering may be halved as compared to equivalent engine configurations without it.

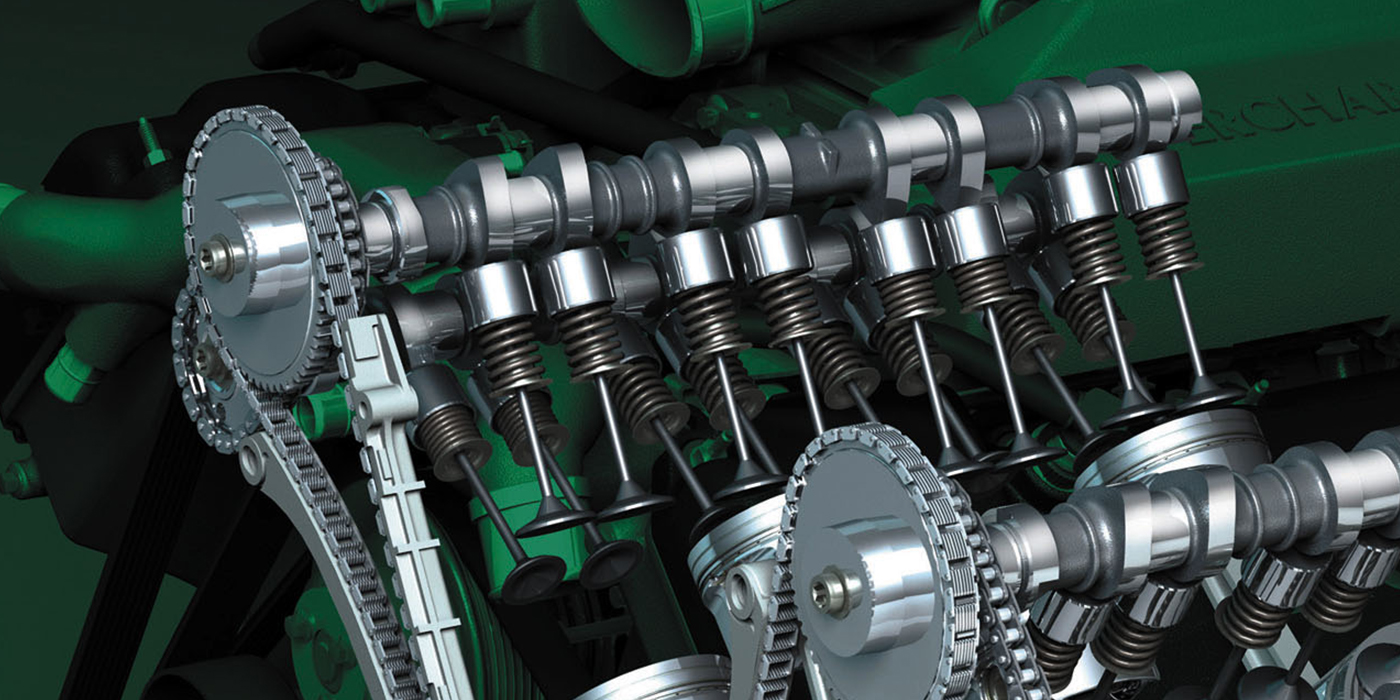

The situation is further aggravated by use of ultra low viscosity motor oils which often compromise wear protection for the sake of fuel economy. The most intense wear occurs at the camshaft bearings, though balancing shaft bearings, main bearings and connecting rod/gudgeon pin systems are all affected as well.

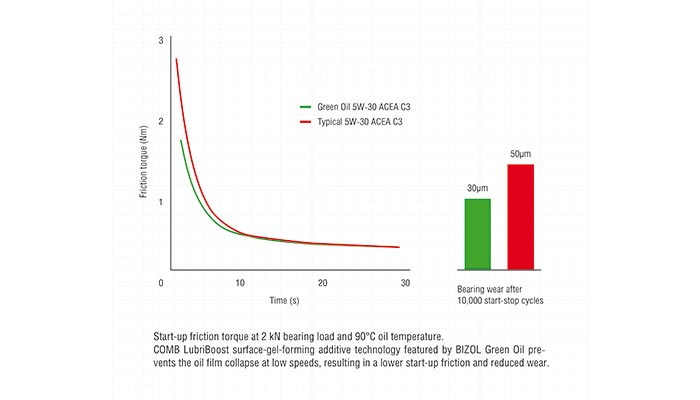

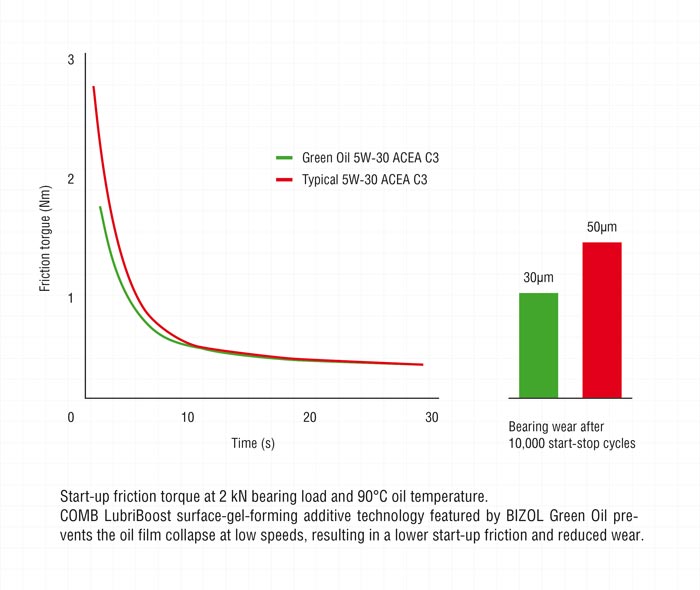

To address these challenges, innovative formulations using COMB LubriBoost technology have been developed, which allows a twofold increase in lubricant film strength and prevents lubricant film collapse even if there is no relative motion between the mating surfaces.

Courtesy of Dr. Boris Zhmud, head of research and development, Bizol Lubricants.