VW/Audi PCV Service

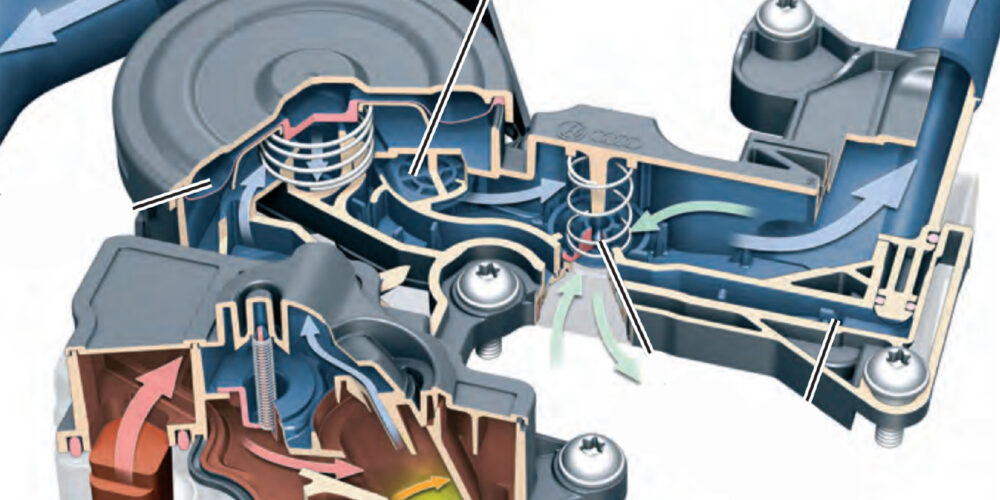

The PCV valve regulates the flow of gases from the crankcase.

Positive crankcase ventilation (PCV) systems have been on just about every vehicle since the late 1960s. The systems route crankcase vapors and droplets into the intake manifold so they are burned in the combustion chamber or catalytic converter.

The PCV valve uses the vacuum from the intake manifold to regulate the flow of gases from the crankcase. The pintle or ball inside the valve moves in response to the pressure difference between the crankcase and the intake manifold. The valve is typically located between the throttle body and cylinder head on a runner for the intake manifold.

Volvo Engine Service

There are many combinations for the Volvo modular engine.

Servicing Mercedes-Benz AMG Brakes

Take a look at some of the things you need to know in order to service the brakes on a Mercedes-Benz AMG vehicle.

AUDI Outside Air Temperature Readings

Incorrect readings can be avoided.

Mercedes-Benz ABC Suspensions

The system provides great ride & handling, but it can be complicated to service if you do not have the right training.

Other Posts

ZF Expands SACHS CDC Shock Line for U.S., Canada

The release expands ZF’s line by more than 70% reflecting growing demand for advanced damping technology in the aftermarket.

Philips Announces Xperion 6000 LED Under Hood Work Light

It features a motion detection switch that allows mechanics to turn the light on and off with a wave of their hand.

Snap-on Announces Latest Software Release

The latest software includes new coverage, guided component tests and features.

Continental Tire Opens Retread Solutions Center in South Carolina

The company said it hopes to uncover new improvements and technologies to innovate the retread process.