Growing up with VWs meant that I had plenty of experience working on drum brakes. Like many young hotrodders, I had my eye on a disc-brake kit for my ‘69 Bug that included lowered front spindles so I could get the California look, which was a front end dropped very low. That was the dream. Disc brakes also performed better and were easier to work on, and they looked good behind the wheels’ spokes.

From a more practical perspective, car companies loved drum brakes because they were less expensive than disc-brake systems. Today, drums still are used on some entry-level vehicles and commercial vehicles, and pickup trucks. Drum brakes typically require less maintenance than disc-brake systems because all of the components are encased between the drum and the backing plate, so they stay out of the elements. This can be good and bad. Driving through water and heavy rain can trap water in the drum and increase braking distances.

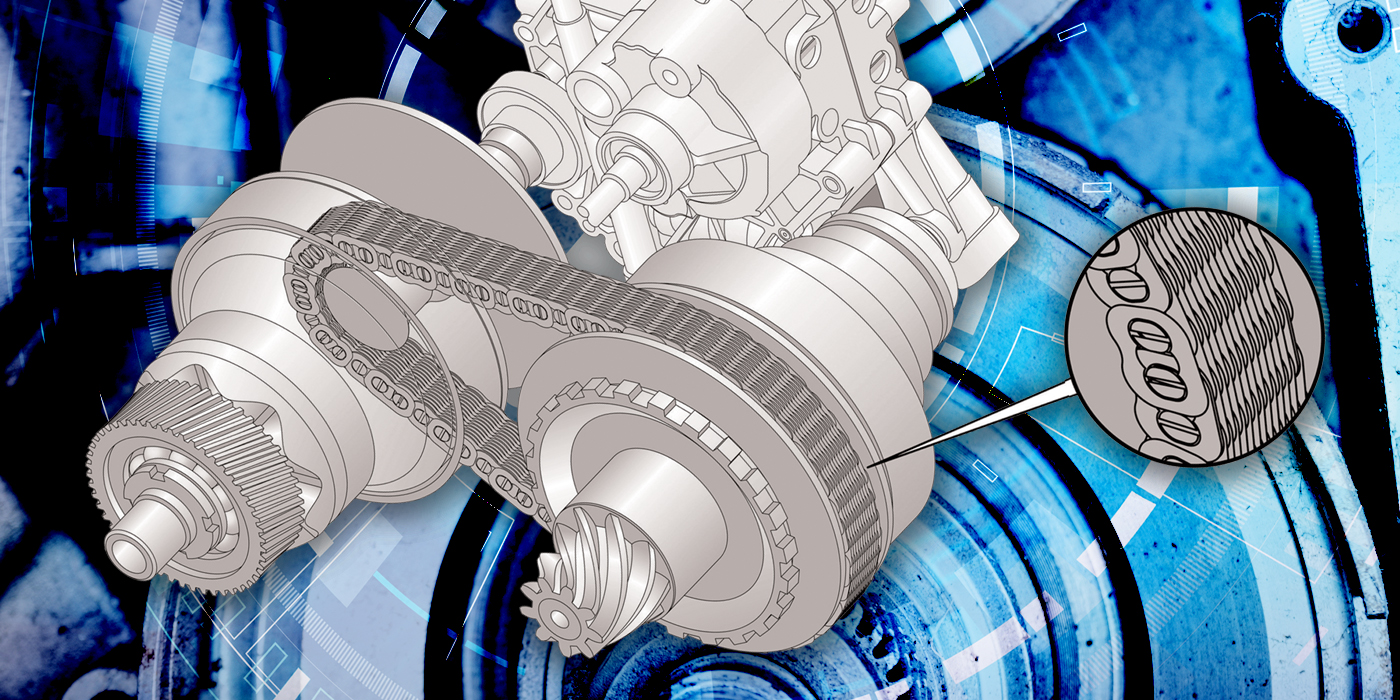

Drum brakes consist of a round drum that contains the wheel cylinder and two brake shoes. The drum rotates with the wheel. When the driver depresses the brake pedal, brake fluid is sent to the wheel cylinder, and it forces the pistons to push into the brake shoes. The brake shoes press against the sides of the drum, creating friction that slows the wheel’s spinning.

Brake drums are more difficult to service because you generally need to remove the wheel and drum to inspect the condition. The shoes also can wear unevenly in the areas where most of the friction is applied. The adjusters can become frozen and create more wear and more play in the pedal as it needs to move the shoe further to stop. There are many hardware parts and pieces to keep track of with drum brakes, and it takes patience, the right tools and practice to replace shoes correctly. You can turn the drum if there’s a ridge on the outer edge. The high spot can make removing the drum difficult and require multiple hammers!

On the other hand, disc brakes consist of a brake caliper, two brake pads and a flat metal rotor that spins along with the wheel. When the brakes are applied, the caliper squeezes the brake pads onto the rotor. This causes friction that slows the rotation of the wheel.

The advantages of disc brakes are that they are resistant to brake fade and are more accessible to service. The rotor is more exposed to air, and with vented fins between both sides, heat is dissipated much faster. Some rotors for performance applications even use slots or vents on the disc’s surface to remove heat quicker, so the brakes are not overheated with heavy and repeated use.

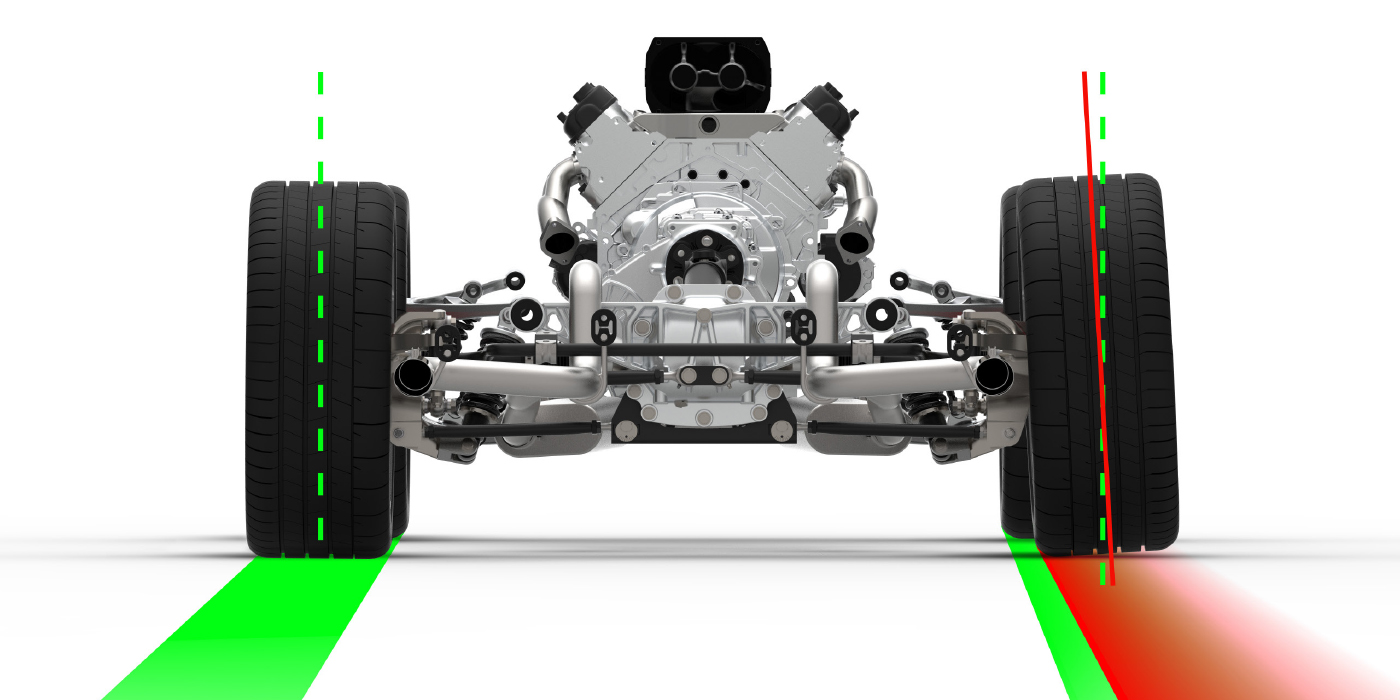

One of the disadvantages of disc brakes (besides higher cost initially) is that they can be noisier than drum brakes due to how they react to the brake and suspension components. Typically, high-frequency noises come from the caliper, rotor or bracket. In contrast, most low-frequency noises are caused by struts, knuckles or even the body structure. One way to ensure brake noises remain at bay is to isolate the pads using a high-quality lubricant and replace the hardware every time you change the brake pads.

Rotors also can create vibrations when they are thicker in some areas than others, which allows the piston in the caliper to be pushed in and out as the driver applies pressure on the brake pedal. In some cases, the rotor can be resurfaced, and other times indexing the disc on the hub will reduce runout (and vibration). As for my ‘69 Bug, the rear brake drum was locked onto the hub so that I couldn’t remove it. I drove it with a leaking rear wheel cylinder until I sold the car. I bought a ‘78 Ford Fiesta with front disc brakes and heat instead!

This article is courtesy of Counterman.