Volkswagen is Europe’s largest automaker and is among the world’s largest automakers. Here in the U.S. market, VW has sold 300,000+ vehicles per year since 2018, so there are a lot of them on the road today. As the warranty period starts to expire on these vehicles, you’ll see more of them heading to your shop. Here are some of the most common oil and coolant leaks you should be looking for.

2.0L FSI Engines (EA113):

APPLICATIONS: Audi A4, A5, S3, TTS. Volkswagen MK5 Jetta & GTI, MK6 Golf R, New Beetle, Passat, CC.

The 2.0L FSI engine was a huge step forward in engine technology for VW. Direct injection, double overhead cams (DOHC) and variable intake valve timing may be common these days, but not when this engine was released. These engines have earned a reputation as being quite reliable, but there are a few potential issues for which to be on the lookout.

The valve cover gaskets on these engines have been known to leak. The original valve cover is made of plastic and featured a permanently attached elastomer seal, but aftermarket valve covers with replaceable seals are now available.

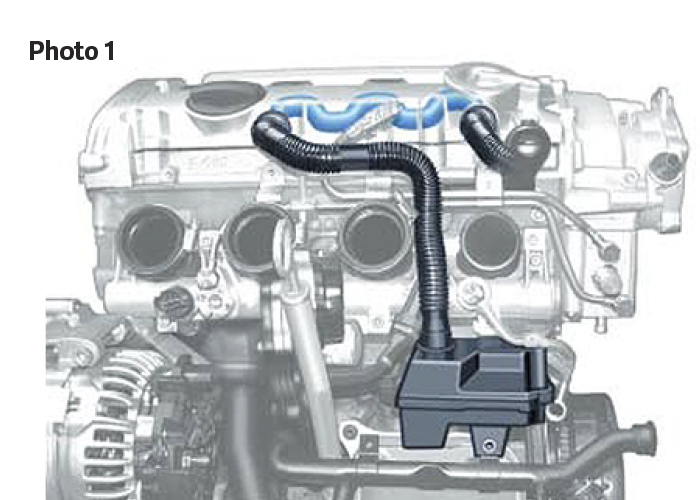

The crankcase breather is another common source of oil leaks. Blow-by gases from the engine block flow into a plastic oil separator on the front of the engine block (Photo 1). From there, the gasses flow upward through the plastic pipe and into the valve cover, and the oil particles drain down into the oil sump. The lower oil separator and the plastic pipe may crack after years of heat cycling, causing oil or vacuum leaks.

1.8L & 2.0L TSI Engines (EA888):

APPLICATIONS: Audi TT, A3, A4, A5, A6, Q3, Q5. Volkswagen Arteon, Atlas, CC, MK6 Jetta & GTI, MK7 Jetta, Golf GTI & Golf R, New Beetle, Passat, Tiguan.

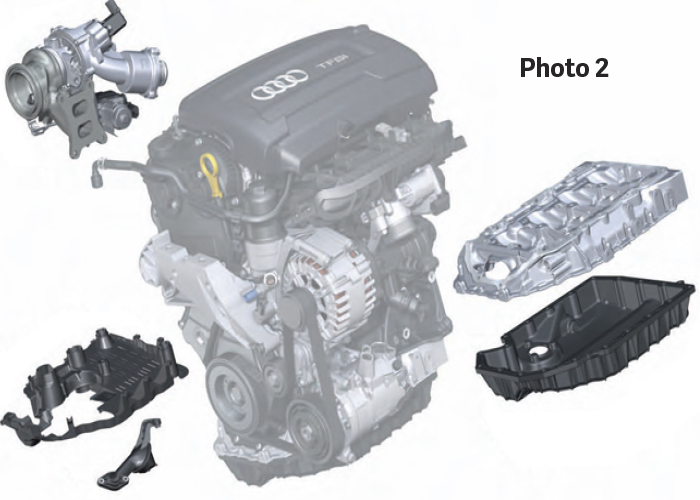

We’ll start off with a less common, but very vulnerable area of the newer Gen3 EA888 engine – the plastic lower oil pan (Photo 2). These oil pans have held up well in the 10 years or so since they were introduced, but there are some things to be aware of. First, the drain plug is also made of plastic, and it is a “quarter-turn” fastener, and it requires a special tool to turn it. If you see signs of oil dripping from the drain plug, there’s a chance that it was over-tightened and cracked or chipped. The lower oil pan is vulnerable to damage from impact, whether it’s road debris, parking barrier or animal strike. It would be wise to replace the pan if it shows any signs of cracking or impact damage.

The next component on our list is a simple one, but still very important – the oil cap. The oil cap needs to remain sealed against the valve cover at all times. If it fails or wears out it could cause oil to leak out into the engine bay, or it could draw unmetered air into the crankcase.

Some engines may exhibit a coolant leak on the front of the engine block. This might be coming from the water pump and thermostat. These two components are bolted together into a modular unit on all EA888 engines. The newer Gen3 engines have been known to leak coolant from the seals between the water pump and the thermostat, or between the pump housing and the engine block.

Since the assembly is installed underneath the intake manifold, it can be rather difficult to pinpoint the exact cause of a coolant leak from this area. You may find it helpful to remove the fan shroud, then use a mirror and a flashlight for inspection. If you are replacing the thermostat or the water pump on a transverse engine, you’ll need to remove the intake air box and the turbo outlet pipe which runs along the top of the transmission housing.

You may find that it’s also worth the extra effort required to remove the intake manifold as well when replacing the water pump or thermostat. This gives you much better visibility and access to the front of the engine block, and you’ll have a much easier time seeing what you’re doing.

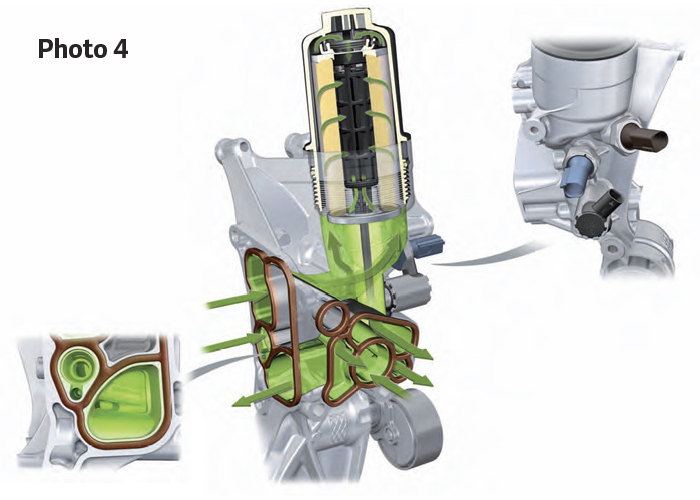

Some EA888 engines may exhibit signs of oil leaking from the engine oil cooler or oil filter housing (Photos 3 and 4). Internal seals keep the coolant and engine oil separate. A leak at this connection could cause coolant to contaminate the engine oil and could be mistaken for a failed head gasket.

The EA888 engine uses two oil separators to remove oil particles from the blow-by gases. These plastic separators will leak oil if they are cracked or damaged. Pay close attention to the breather pipes which connect to the fine oil separator on top of the valve cover; they can become brittle over time and can break quite easily.

ALL VW/Audi Engines:

Let’s wrap up our list by looking at some common leak points which are shared by many different VW/Audi engines.

Plastic is used in abundance on these vehicles to reduce curb weight and manufacturing costs. The most common example of this would be the couplers and fittings used in the coolant hoses. This plastic can become brittle after it has been subjected to years of hot and cold cycles. It’s a good idea to look closely at any plastic unions, tees, and end fittings under the hood whenever you’re performing a repair or inspection.

This also applies to the plastic radiator end tanks. A small crack can be difficult to locate, so you may need to remove the fan shroud to locate it like we did (Photo 5). These radiators are rather well protected from the elements thanks to their location behind the condenser and intercooler, but they can still become brittle over time from heat cycling.