The Jeep Patriot is a crossover vehicle produced by Jeep and Chrysler. The same basic platform is used for the Sebring, Avenger, Dodge Caliber and Mitsubishi Lancer.

The Jeep Patriot is a crossover vehicle produced by Jeep and Chrysler. The same basic platform is used for the Sebring, Avenger, Dodge Caliber and Mitsubishi Lancer.

This is a “Net Build” vehicle with only toe adjustments built into the vehicle. Some adjustments for caster and camber can be made by moving the subframes.

There are differences in the caster, camber and toe for the different wheel sizes, options like AWD and the different trim levels, make sure you look at the vehicle before selecting the correct alignment specifications. No scan tools or procedures are required to reset the steering position sensor.

FRONT CAMBER AND CASTER

FRONT CAMBER AND CASTER

Front camber and caster settings on this vehicle are determined at the time the vehicle is designed, by the location of the vehicle’s suspension components. The result is no adjustment of camber and caster after the vehicle is built or when servicing the suspension components.

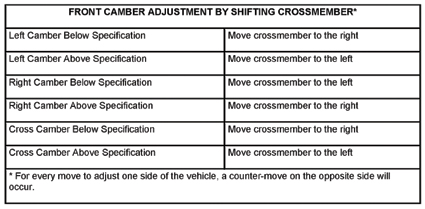

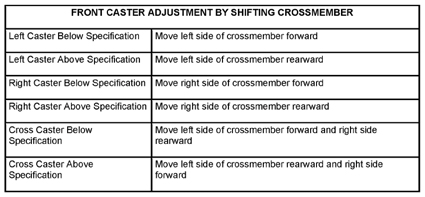

When performing an alignment, caster and camber are not adjustable angles with conventional methods. Chrysler recommends shifting the cradle to adjust the camber and caster. Camber is adjustable with a lower bolt kit for the strut. The kit will only give ±1º of camber. Aftermarket camber adjustment bolts are also available from various manufacturers.

When performing an alignment, caster and camber are not adjustable angles with conventional methods. Chrysler recommends shifting the cradle to adjust the camber and caster. Camber is adjustable with a lower bolt kit for the strut. The kit will only give ±1º of camber. Aftermarket camber adjustment bolts are also available from various manufacturers.

The camber adjustment bolt package contains new bolts and nuts for attaching the strut clevis bracket to the steering knuckle. The bolts contained in the package are slightly undersized allowing for movement between the strut clevis bracket and the steering knuckle.

The movement allowed by the undersized bolts provide approximately two degrees of camber adjustment per side of the vehicle.

REAR

The toe is adjustable by the toe link and the adjustable cam bolt on the inboard side.

Rear camber settings on this vehicle are determined at the time the vehicle is designed, by the location of the vehicle’s suspension components. This is referred to as Net Build. The result is no required adjustment of camber after the vehicle is built or when servicing the suspension components. Thus, when performing a wheel alignment, rear camber is not considered an adjustable angle.

CURB HEIGHT MEASUREMENT

Vehicle height is to be checked with the vehicle on a flat, level surface, preferably a vehicle alignment rack. The tires are to be inflated to the recommended pressure. Vehicle height is checked with the fuel tank full of fuel, and no passenger or luggage compartment load.

Vehicle height is not adjustable. If the measurement is not within specifications, inspect the vehicle for bent or weak suspension components. Compare the parts tag on the suspect coil spring(s) to the parts book and the vehicle sales code, checking for a match. Once removed from the vehicle, compare the coil spring height to a correct new or known good coil spring. The heights should vary if the suspect spring is weak.

Prior to reading the curb height measurement, the front and rear of the vehicle must be jounced to settle the suspension. Induce jounce by pushing down on the center of the bumper (fascia), using care not to damage the vehicle, moving the vehicle up and down, gradually increasing the suspension travel with each stroke. Release the bumper at the bottom of each stroke, repeating this action several times. Perform this to both front and rear suspensions an equal amount of times.

Measure curb height as follows:

1. Jounce the vehicle. Refer to above note.

NOTE: On some vehicles it may be necessary to remove an engine belly pan in order to gain access to the lower control arm pivot bolt.

2. FRONT – On each side of the vehicle, measure the distance (2) from the lower control arm rear (vertical) pivot bolt head (1) to the floor or alignment rack/lift runway surface. It may be necessary to measure to the bottom of a straight edge (3), placed from lift runway to runway, to get an accurate measurement.

3. REAR – On each side of the vehicle, measure the distance (2) from the center of the outboard trailing arm-to-body mounting bolt (1) to the floor or alignment rack/lift runway surface.

4. Compare the measurements to specifications. Cars with 15-inch wheels should have a measurement of 205 mm (8.07”) in front. In the rear, these models should have 329 mm (12.95”). For all other models, the ride height in the front should be 214 mm (8.43”) and 338 mm (13.31”) in the rear. The ride height should not vary more than 8 mm (0.32”) from the specifications. Maximum left-to-right differential is not to exceed 12.5 mm (0.5”).

5. If curb height is found to be out of specification and there is no sign of excessive body damage, curb height can be changed by replacing the applicable spring with a spring offering a different check load.