It was a quiet Tuesday morning, about 15 minutes before opening the shop doors. All the techs were busy performing their morning rituals – drinking coffee, reading trade publications and oiling their air tools. Without warning, our otherwise tranquil morning was interrupted by a horrendous screech of brakes, as a late-model, metallic blue BMW M3 slid into the service drive. Steam was billowing out from underneath the engine compartment. The driver, a moderately dressed, thirty-something suburbanite, jumped out and opened the hood. Instantly, a huge white cloud engulfed him and the entire front half of the car. I fully expected that when the fog cleared, at least one of them would have vanished – like a magician’s disappearing act.

Before I could get out of the door to lend a hand, the car’s owner emerged from the steam cloud and sprinted for the office. Breathless and clearly shaken, the driver yelled as he came through the door, "Man, you got to help me! I think my "Beemer" is on fire. There is so much smoke, I can’t even see the engine." "Calm down," I said. "It’s only steam. You have a coolant leak. Why don’t you have a seat and we’ll let it cool down a little before we take a look at it."

He seemed comforted by the fact that his car wasn’t going to burn to the ground. While the steam cloud was dissipating, I got all the necessary information from him and then went out to push the car into the shop for a detailed inspection.

There was coolant all over the engine compartment, so at first, it was hard to pinpoint where the leak was coming from. We began filling the radiator and before it was full, water began to leak out of a hole in the upper radiator hose.

It looked like the hose had been rubbing on the oil filter housing and had created a hole. Strangely, the hose wasn’t really touching the oil filter housing at that time. I decided to check ALLDATA Online for a BMW factory technical service bulletin that could shed some light on this problem.

Great! There was a bulletin that covered this exact problem and here’s what it described:

Some BMW M3 models, produced from September 1995 through June 1996, equipped with the M54, S50, or the S52 engine, may have an upper radiator hose that can come in contact with the oil filter housing only when the engine coolant is at operating temperature. The contact is due to coolant system pressure and expansion of the hose.

Checking the clearance between the upper radiator hose and the oil filter housing must be performed when the engine is cold.

1. Visually inspect the upper radiator hose for pressure marks and traces of rubbing at the closest point of contact to the oil filter housing cast boss. (See illustration)

1. Visually inspect the upper radiator hose for pressure marks and traces of rubbing at the closest point of contact to the oil filter housing cast boss. (See illustration)

• If traces of rubbing are found, the upper radiator hose must be replaced with the new style hose (See Parts Information).

NOTE: A modified hose was used in production from approximately mid-November 1995 through June 1996, which included an extra rubber pad attached to the outside of the hose in the critical area.

• If traces of rubbing are found on the rubber pad area of this type of hose, it must also be replaced with the new style hose (See Parts Information).

2. Visually inspect the oil filter housing for any sharp edges (casting burr) on the casting boss.

• If a sharp edge (casting burr) is found on the casting boss, it must be removed using sand paper or a fine file.

CAUTION: Cover up the drive belts and pulleys using a clean shop rag before sanding or filing to prevent metal filings from falling onto them.

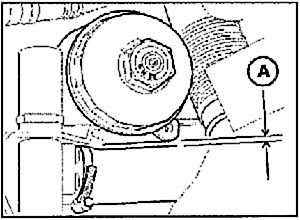

3. If no pressure marks or traces of rubbing are found on the hose as described, check the gap at the closest point (A) between the cast boss of the oil filter housing and the upper coolant hose.

4. There must be a gap (A) of at least 1/4 inch (7 mm) when the engine coolant is cold.

• If gap (A) is 1/4 inch (7 mm) or greater, no further repairs are necessary.

• If gap (A) is less than 1/4 inch (7 mm), the upper coolant hose must be replaced with the new modified version.

Parts Information:

Description — Upper Coolant Hose

BMW Part Number — 11 531 433 340

We replaced the upper radiator hose with the new type, cleaned the engine compartment, filled the cooling system and pressure tested it to make sure there were no other leaks. Luckily, the engine hadn’t overheated. Most of the steam was created from the coolant leaking on the exhaust manifold. The owner was fairly good-natured about his near catastrophe. Relieved, standing at the counter while paying his bill, he said lightheartedly, "You know, my pants and shirt were badly wrinkled when I left the house this morning. I think this was the strangest way I’ve ever had my clothes pressed." I had to agree.

Writtenby ALLDATA Technical Editor, Rich Diegle. Rich is an Advanced EnginePerformance Certified and ASE Master Technician with an Associate ofArts degree in automotive technology and 22 years of dealership andindependent shop experience.

For additional information, visit www.alldata.com.