Nothing is worse than a customer returning to your shop after a brake job complaining of a noise or performance issue. These comebacks can be frustrating because they cost your shop’s productivity and reputation.

Nothing is worse than a customer returning to your shop after a brake job complaining of a noise or performance issue. These comebacks can be frustrating because they cost your shop’s productivity and reputation.

Below are 10 tips that can help you solve a brake comeback due to noise in less time.

1. Interview the Customer: Customer interviews are critical to the noise location process. Keep in mind that the grinding noise that you hear might not be the squeaking noise that the customer hears. In most cases, a test drive with the customer might help to identify the noise with which he or she is most concerned.

If the noise is intermittent, use a checklist to help identify the conditions under which the noise occurs. Is it a cold- or warm-weather noise? Does it occur when the wheels hit a tar strip or does it occur more frequently on a gravel or washboard surface? Is it a squeaking, chirping, rattling, knocking or clunking sound? Or is it a wheel-speed or an engine-speed noise?

If possible, take a test drive with the customer. Often, many noise complaints are not related to the brakes.

2. Check TSBs: Brake noise is one of the greatest concerns for automakers. A Technical Service Bulletin (TSB) can tell you if there are updated parts or even if other items on the vehicle can be to blame for the noise, like a chattering differential or sloppy driveshaft.

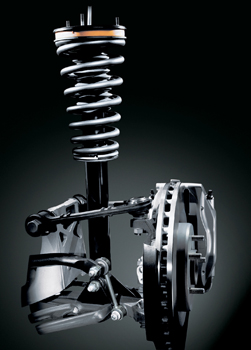

3. Inspection: If a customer is complaining of brake noise, take some time to inspect the entire vehicle. Brake noise could be increased, mimicked and caused by other components like a worn strut mount, tie-rod end and even drivetrain components.

3. Inspection: If a customer is complaining of brake noise, take some time to inspect the entire vehicle. Brake noise could be increased, mimicked and caused by other components like a worn strut mount, tie-rod end and even drivetrain components.

If the vehicle has accumulated more than 500 miles since the brake job was performed, measure rotor runout and disc thickness variation.

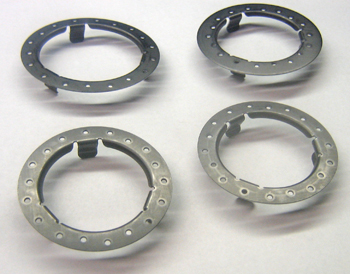

4. Hardware: Brake hardware is necessary to keep the pads moving smoothly in the caliper. If the pads are loose or bind in the caliper, it will cause noise. The leading causes are mis-installation of the hardware and corrosion, or the components they attach to. Not taking the time to clean and remove rust from bracket and caliper can cause a mis-alignment of the components. Often, the caliper bracket can be corroded to the point where there are pits and voids on the machined surfaces.

One option is to pool or braze welding material in the voids on the bracket and grind the surfaces level. This can be very labor intensive, but required on some vehicles where the slides are on the knuckle. Some brake pad manufacturers have developed special clips that can cover the surface. Also, new caliper brackets for most applications are available through most jobbers.

Heating and cooling cycles can weaken springs and anti-rattle clips, this is why they should not be reused. Some springs and clips can be difficult to install. Some anti-rattle clips may resemble Chinese finger traps when you are trying to reinstall them back on the car. But leaving them out is not an option.

5. Shims: Never reuse a shim. Shims can be damaged by the caliper fingers and pistons. In an average pedal application, the shim can be exposed to more than 2,000 lbs. of force. Over a lifetime, this can distort any shim.

5. Shims: Never reuse a shim. Shims can be damaged by the caliper fingers and pistons. In an average pedal application, the shim can be exposed to more than 2,000 lbs. of force. Over a lifetime, this can distort any shim.

Most shims are made of a layers of metal and plastic/rubber materials. The metal can corrode and cause the shim to delaminate. The soft materials can lose their elasticity and ability to dampen vibrations.

Most new pad sets include shims, and the quality of the shim typically reflects the quality of the brake pad.

New OE and aftermarket shims can be purchased separately from the pad sets. Some automakers even introduce shims to combat their noise problems that happen while the vehicle is under warranty.

Another option is an aftermarket shim that attaches to the piston. This shim can act as a noise barrier that prevents noise from being transmitted to the caliper. It can also insulate the piston against heat.

6. Lubricants: Brake lubricant can also be used to isolate vibrations between disc brake pads and the caliper/bracket. Use it on the back of a bare pad or between the pad shim and caliper – and use it sparingly. If you are using a two-piece or clip-on style shim, a light coating can be applied to the shims. Don’t glob it on. Excessive lubricant attracts debris that can cause a caliper to stick.

The primary lubrication points in rear drum brakes include the raised pads on the backing plates that support the shoes, the star adjuster mechanisms, hinge points for self-adjusters or the parking brake linkage, and the parking brake cables.

7. Rotor Finish: Poor rotor finish can lead to noise. When machining a rotor, you have two primary goals: Provide a smooth surface finish for the pads and provide a true surface finish.

7. Rotor Finish: Poor rotor finish can lead to noise. When machining a rotor, you have two primary goals: Provide a smooth surface finish for the pads and provide a true surface finish.

The smoothness of the friction surface of a rotor is described in terms of micro-finish or RA factor. RA stands for “roughness average” and represents a way to measure the smoothness of a rotor. Most lathes out there, when in good condition and used properly, will yield very acceptable RA factors. The finish is essential to transfer material for organic and ceramic friction materials. Also, the correct finish is essential for semi-metallic pads so they can have the correct coefficient of friction during initial break-in.

Non-directional finishes can help in the bedding process and the establishment of a transfer layer. It can also prevent the grooves of the rotor from pulling and pushing on the pad, much like how a record moves a needle. Always clean the rotor’s surface after machining the rotor. This removes metal fragments that can contaminate the pad.

8. Caliper Issues: A caliper can cause a noise-related comeback.Every floating caliper has bushings that are designed to isolate vibration in the caliper. These bushings should last at least two sets of pads. These bushings are on the end or are around the guide pins. Over time, these pins can become compressed and lose their elasticity. This can cause movement in the caliper and maybe noise. It can also cause uneven application of the pads.

9. Wheel bearings: A worn wheel bearing can cause brake noise and even a low pedal. Too much end play can result in uneven application of the pads. When the pads do not contact the rotor evenly, it can result in a noise complaint.

If the wheel bearing’s flange has too much runout, it can cause disc thickness variation or in extreme cases, a low pedal. Even if there was no pulsation right after the brake job, a pulsation problem will occur in 2,000-5,000 miles.

Lateral runout can be corrected by replacing the bearing or flange. A less expensive option is to use a plate that can be placed between the rotor and flange.

10. New pads: Choosing to install a new set of pads should be the last option when trying to solve a noise complaint. Most of the time, the pad is not to blame if you use a high-quality pad.

Look at the surface of the pad for any discoloration, cracking or glazing. These are signs of contamination of the friction surface. In order for a pad to operate quietly, it must have a consistent coefficient of friction across the face of the pad that comes in contact with the rotor. If an edge or half of the pad is contaminated by brake lube, metal shavings from the lathe or even friction material from to old set of pads, it will cause a noise comeback.

Most ceramic pads transfer a layer of friction material to the rotor. This can improve rotor life and braking performance. If the brake pads are changed and the transfer layer of material is left on the rotor, the friction material can become contaminated and the new material might not transfer its material to the rotor. Some friction materials might be compatible, but chances are the two materials will have problems.

When a rotor is machined or a new rotor is installed, it should be cleaned. The surface should be free of shavings and anti-corrosion coatings. These materials can contaminate the pad and affect the levels of friction across the pad.

One place you never, ever want to get any grease on is the friction surface of a brake lining — which is another reason for not using low-temperature or petroleum-based lubricants which can melt, run off and foul the linings. Grease contaminated shoes or pads will be grabby and usually cause a brake pull to one side. This is why any lubricant should be used sparingly.

In most cases, the contamination can’t be removed from the pad. The pad should be replaced and the rotor machined.

Returning pads is getting more and more difficult. Some friction suppliers have even eliminated returns for some of their lines.