Disc brake service has become routine for most import repair shops and, for the most part, offers very few surprises for the service writer and technician alike. Many shops service disc brake calipers by simply replacing them with loaded caliper assemblies, which makes sense in rust-belt areas. In drier climates, calipers can last for many years and may require only routine inspection during a disc brake pad replacement.

Nevertheless, in order to appreciate some of the fine points of disc brake repair, it’s important to review the basic elements of caliper service. In the following text, I’ll use a typical caliper service to illustrate some of the issues involved in disc brake service.

CALIPER DIAGNOSIS

Most disc brake services begin with a routine maintenance inspection or with a customer complaint, such as a brake pull or noise. Many caliper failures result in brake-pull complaints because the caliper piston fails to retract. To allow free rotation of the wheel, a very small air gap must exist between the rotor and brake pad. When the pads on one wheel drag against the rotor, the pad may glaze or the brake assembly temperatures may sufficiently increase to change the coefficient of friction between the driver- and passenger-side disc brake assemblies. A change in the coefficient of friction will obviously cause a brake-pulling complaint.

Last, but not least, a low master cylinder reservoir fluid level might indicate that the brake pads are excessively worn. In such instances, brake fluid supplied by the reservoir is used to fill the caliper bore as the caliper piston extends to compensate for pad wear. In any case, a low fluid level at the master cylinder reservoir indicates the need for a thorough brake system inspection.

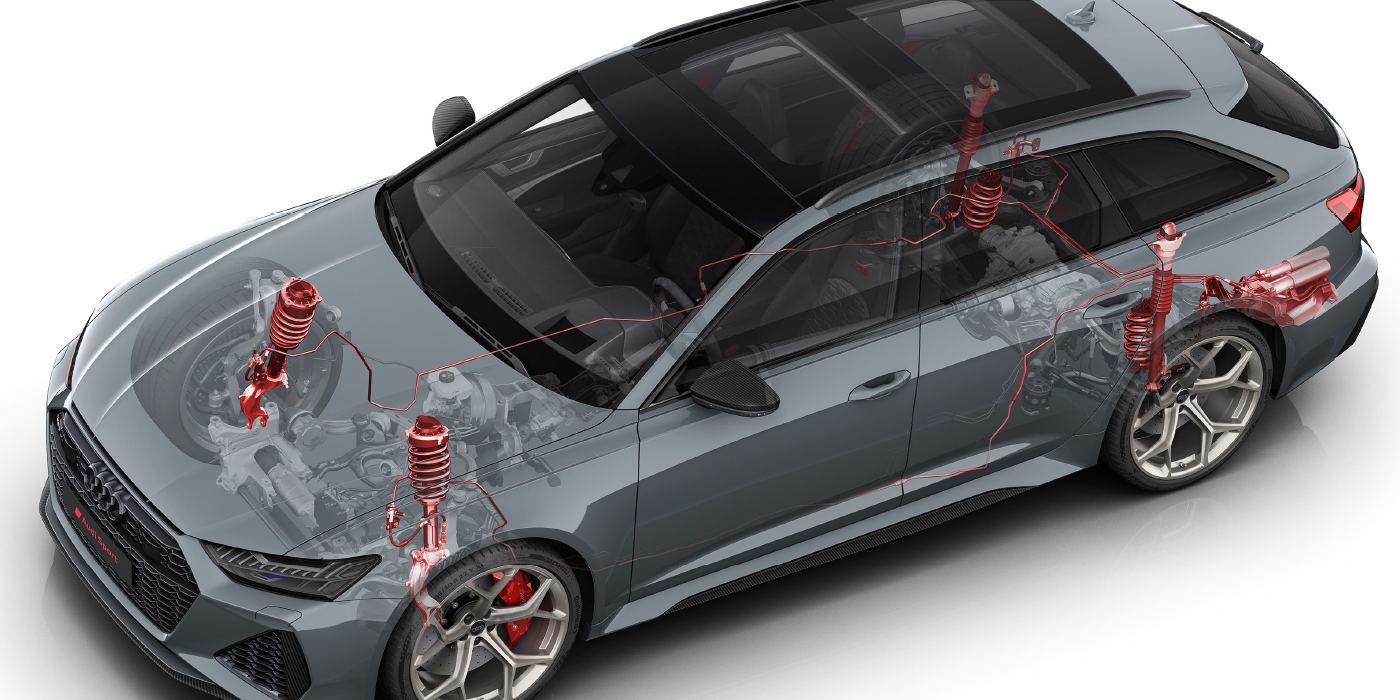

TYPES OF BRAKE CALIPERS

Modern disc brake calipers are either floating or fixed designs. To allow the brake pads to align themselves with the brake rotor, most late-model vehicles incorporate a single-piston, floating caliper assembly that moves in relation to the wheel spindle. In contrast, the fixed calipers used in many high-end and high-performance vehicles are firmly attached to the steering knuckle and spindle. When dealing with a fixed caliper, remember that multiple caliper pistons do the work of aligning the pads with either side of the disc rotor. (Click here for information on loaded brake calipers.)

BRAKE CALIPER INSPECTION

Brake pad wear is usually a good indicator of caliper condition. A seized floating caliper may, for example, wear the inboard pad more than the outboard pad. See Photo 1. Either type of caliper — fixed or floating — will cause the brake pads to drag against the rotor when the pistons are seized into the caliper bores. In addition, the caliper boot should not show any signs of fluid leakage nor should the caliper boot appear hardened or cracked (see Photo 2). If a defective caliper boot allows moisture to accumulate between the caliper bore and piston, the piston will eventually corrode and seize in place.

Calipers with integrated parking brake hardware should be inspected for fluid leakage and correct parking brake operation, and service brake pedal travel. In some applications, the parking brake must be used regularly to compensate for brake pad wear. If the driver doesn’t use the park brake regularly or if the parking brake cable or caliper hardware is seized, excessive service brake pedal travel might result.

BRAKE CALIPER SERVICE

Although you’re not likely to rebuild a disc brake caliper in the near future, it still pays to understand how the operation is performed. In the rare instance, you might find yourself rebuilding the original calipers on a classic or collector import vehicle. So, to better understand disc brake service, let’s work through the basics of servicing a disc brake caliper.

First, it’s important to establish safe work habits before beginning any hydraulic brake service by consulting an appropriate service manual. The pressure in the anti-lock brake accumulator should be released by pumping the brake pedal as specified by a service manual or until the pedal feels hard. Next, the bleeder screw should be loosened to allow old fluid to be flushed out of the caliper bore. In some cases, a clogged bleeder screw must be removed for cleaning or replacement. If the bleeder screw is seized, it’s probably cheaper to replace the caliper.

There are two schools of thought on preventing debris from being flushed into the anti-lock braking and master cylinder assemblies when the piston is seated in the caliper bore. The first “school” opens the bleeder screw to relieve pressure as the caliper piston is seated. The second “school” clamps the brake hose closed with a pair of hose-clamping pliers to prevent debris from back-flushing into the master cylinder. The first-school method is the most commonly accepted because there’s less chance of inadvertently damaging the hose.

CALIPER DISASSEMBLY

Seized caliper pistons can be difficult and dangerous to remove, so always proceed with caution. Perhaps the safest method is to bottom the piston with a common C-clamp to push out excess fluid, and then ease the piston from the bore by gently applying air pressure to the brake hose port while backing out the C-clamp screw (see Photo 3). When the piston is ready to exit the bore, cover the caliper assembly with a shop towel to prevent the brake fluid from spattering. If the piston is so badly seized that it doesn’t respond to controlled air pressure, the caliper should be replaced. See Photo 4.

Because the piston surface seals the brake caliper, the piston should be in like-new condition. If the piston is pitted or scored, it should be replaced, or the caliper assembly replaced, with new or remanufactured.

Replacing the boot often requires a dedicated tool to press the boot into the caliper bore. In many cases, a seal driving tool or an old bearing race can be used to press the boot into the bore without damaging the boot. See Photo 5.

The most common method for installing the piston into the boot is to hold the piston in place with a piston seating tool while inflating the boot with compressed air (see Photo 6). This method works well on small-bore calipers. Boot expansion tools must generally be used on large-bore calipers with shallow-boot designs.

The piston must be perfectly square with the bore before it will pass through the flat-cut O-ring in the caliper bore. The simplest method is to use a square bar to gently rock the piston from side-to-side until it drops into the caliper bore (See Photo 7). A wooden 2×4 plank works well on larger bore caliper pistons.

Once the piston is installed, carefully remove the caliper guide pins and lubricate them with synthetic caliper grease or the OEM-recommended lubricant. When installing the caliper bracket bolts, apply thread-locking compound, if required. In other cases, lightly oil the bolts and torque them to specification. Always install new caliper hardware on the caliper bracket to prevent pad rattle and dampen pad squeal. See Photo 8.

A correctly serviced caliper should slide smoothly on its guide pins or guide surfaces, and should allow the rotor to turn freely when brake pedal pressure is released. If the caliper won’t release, the interior rubber of the brake hose might be peeling and blocking the return of fluid to the master cylinder reservoir. In other cases, the master cylinder push rod or brake pedal height might be incorrectly adjusted, which prevents the master cylinder from releasing the fluid pressure from within the caliper.