Wheel Bearing Diagnosis

A sealed hub assembly or bearing cartridge typically contains two sets of bearings: an inner set and an outer set. They may be ball bearings or tapered roller bearings. Tapered bearings have cylindrical rollers between the inner and outer race.

New Wheel Bearing Technology

For an engineer, wheel bearing design and selection can be a balancing act between durability, cost and fuel economy. A large bearing might be great for potholes and heavy loads. But, there is only so much room in the hub and knuckle. Also, the larger bearing might have increased rolling resistance due to a larger sealing surface.

Mercedes-Benz: Installation guidelines for Smart Car front wheel bearing

The typical solution for replacing the front wheel hub on a 2008-‘13 Mercedes-Benz Smart Car is a front wheel hub assembly, including a front wheel hub and knuckle. However, with a wheel hub-only solution for the Mercedes Smart Car, like the one offered by SKF, the installer can press the hub unit into the knuckle

Diagnosing Hyundai Wheel Bearing Failure

While wheel bearing noise is one of the toughest problems for the customer to describe, it’s not unusual for it to come on so gradually that the customer may not even notice it until you mention it after an unrelated road test. Many times, the customer complaint will send you down the wrong path if you let it.

Hyundai Feature: Drivetrain Noises And Wheel Bearing Replacement

Don’t let customers lead you down the wrong diagnostic path. While wheel-bearing noise is one of the toughest problems for customers to describe, says Import Specialist Contributor Bob Dowie, it’s not unusual for it to come on so gradually that the customer may not even notice it until you mention it after an unrelated road test.

Wheel Bearing Torque Dos and Don’ts

While it may appear to be easier to use an impact wrench, it is not recommended. OEM and bearing manufacturers always recommend using a torque wrench for installation. During removal, an impact wrench can damage the axle nut threads and shock the CV joints. It can also create a false sense of security when adjusting a nut or bolt, which may be under or over torqued.

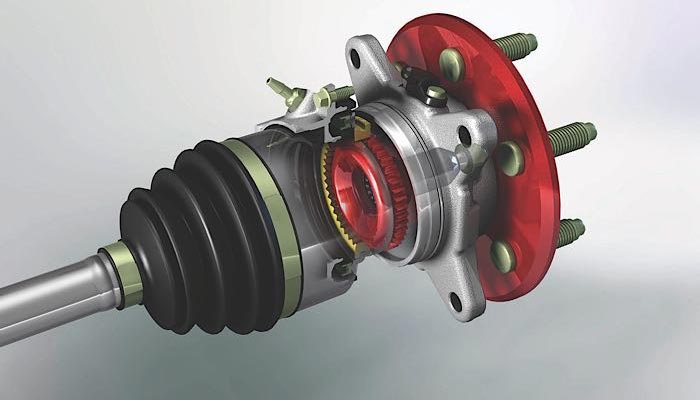

Tech Tip: Generation 1 Wheel Bearings With Integrated ABS Tone Ring

The front wheel bearings listed in this Tech Tip all share a unique design feature. They are all double-row angular contact with a split inner ring. The distinctive feature on these bearings is that one of the two seals on the bearing has a built-in magnetic impulse wheel. Caution should be taken to make sure that the seal with the ABS impulse ring is installed in the correct direction.

TECH TIP: WHEEL BEARING HUB AXLE NUT TORQUING

Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating while in operation. The torque specification for this center nut is critical to the performance and longevity of the hub.

Servicing Wheel Bearings And Wheel Speed Sensors

If you are replacing a wheel bearing on a late-model vehicle, you will be dealing with a wheel speed sensor. In the past decade, wheel speed sensors have been moving from differentials, axles and knuckles to inside or on the wheel bearing or hub unit. At this location, the sensors are more accurate and often more protected from the elements.

Identifying The Toughest Wheel Bearing Jobs

Some wheel bearing jobs are easy. These are typically unitized hub units. All that is required is removing the caliper, rotor, axle nut and the four bolts holding on the unit. Some wheel bearing jobs can take as many as three hours and require removal of the knuckle from the vehicle. Collected in this article are some of the most difficult vehicles as reported by technicians, labor guides and bearing manufacturers.