Replacing Motor Mounts on 2013-2018 Santa Fe Sports

Follow along this step-by-step guide to learn how to replace motor mounts on 2013-2018 Santa-Fe Sports. Sponsored by PRT.

New Motor Mount Technology

Engine speed is the primary input that determines the stiffness of the mount.

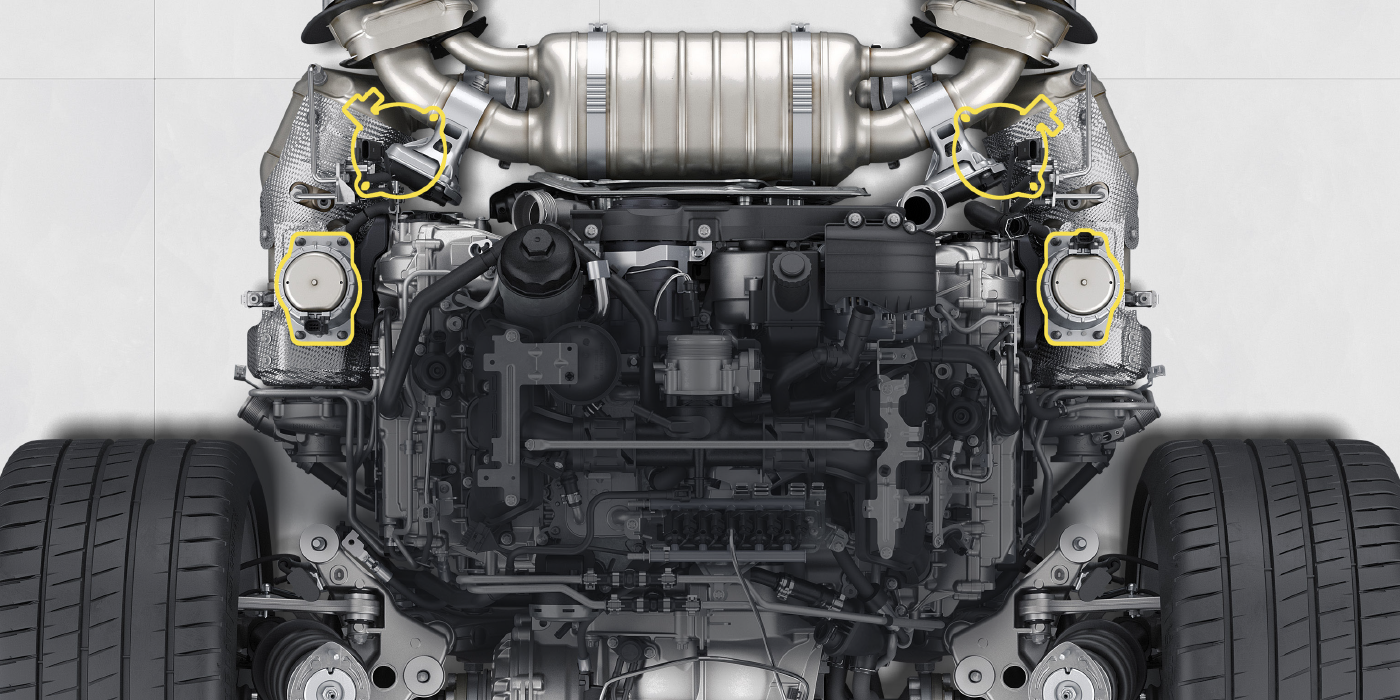

Porsche Active Motor Mounts

Over the years, motor mounts have evolved from when they were just an item to mount the engine to the frame or unibody.

VIDEO: Motor Mounts And U-Joints: How One Affects The Other

Andrew Markel discusses the relationship between motor mounts and U-joints, and how position changes in the engine can affect U-joints and CV axles. Sponsored by Auto Value and Bumper to Bumper.

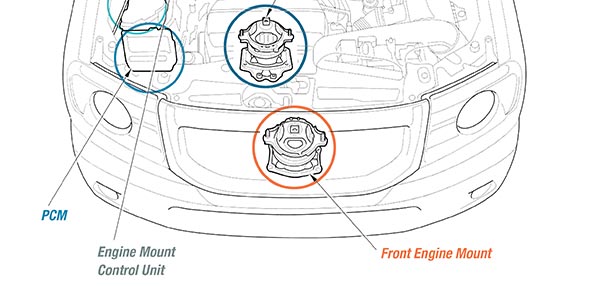

Diagnosing Active Motor Mounts On Asian Vehicles

Many automakers, including Toyota and Honda, have changed their lineup of engines to improve fuel economy and emissions. Gone are the high-revving 1.8L and 2.0L four-cylinder engines. Replacing them are engines with displacements ranging from 2.3L to 2.5L. These engines are more efficient and produce more power lower in the power band. But, these new engines increase the stroke and not the bore, making for some unique vibration conditions the motor mounts have to minimize.

VIDEO: Honda’s ACM Active Motor Mount System

Jason Stahl discusses active motor mounts, specifically Honda’s ACM system, and how it communicates with the BCM. Sponsored by Intermotor.

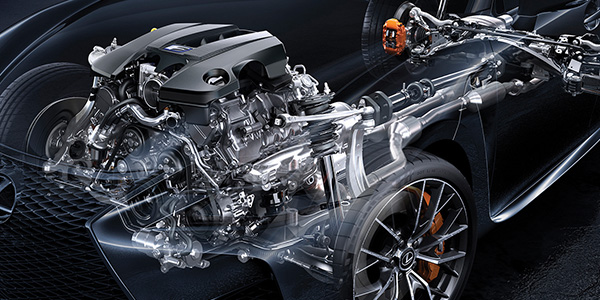

Motor Mount Logic

Engines have noticeably changed in the past decade. Fewer cylinders, more power at lower RPM and more detectable vibration at idle are just a few of the differences in today’s engines. With these changes, it should be no surprise that engine and transmission mounts have taken on new importance. New technologies are being used that access information from the engine to anticipate vibration before it reaches the driver.

Diagnosing And Servicing Active Motor Mounts

Engine vibration is usually most noticeable when the engine is idling, especially if the engine has an odd fire configuration as some V6 engines do. Four cylinder engines, as well as diesels, can also produce a lot of vibration at idle. Vibrations can be amplified even more when high-load belt-driven accessories, such as the A/C compressor, are engaged while the engine is idling.

Diagnosing And Servicing Active Motor Mounts

For many years, auto makers relied on solid rubber motor mounts to support the engine. The natural flexibility in rubber allows the mounts to absorb vibration. However, if the rubber is too compliant, the engine may experience excessive motion under load that could stress and crack exhaust pipes and connections. And with such tight clearances under the hood, there’s a risk of something rubbing against something else and causing additional noise or problems. So the rubber in the mounts has to be relatively stiff to limit compliance so the engine does not rock excessively when it is under load.

Giving Off Bad Vibes: Motor Mount Replacement Tips

Most motor mounts are relatively simple in design and consist only of metal attachment plates and large rubber insulator blocks. But, some vehicles have “hydraulic” or “hydro-mounts” with hollow chambers filled with glycol or hydraulic fluid.