Although Car Care Month is typically celebrated twice a year in April and October, that doesn’t mean you should miss great opportunities to host impromptu car care clinics during the summer.

Your customers may leave it all behind but vehicle maintenance needs never take a vacation. While drivers may be putting enormous numbers of miles on their cars all summer long, starting with Memorial Day vacation travel through the craziness of a long Independence Day weekend right up through the day they send kids off to school, summer is a great time to ensure that everyone gets where they’re going safely.

Offer a free carwash on a sunny Saturday morning – while scrubbing the grime, take a close look at the condition of the external body panels and tires. Give free inspections of cabin air filters, wipers, batteries, fluids, tires and diagnostic trouble codes.

You customers may not know what to look for when it comes to maintenance items on the their cars, so explain in simple terms – and by pointing out worn parts – what a clean versus a dirty air filter looks like, how wiper blade wear can cause streaking and chattering, and how a damaged serpentine belt can end the dream vacation in a hurry.

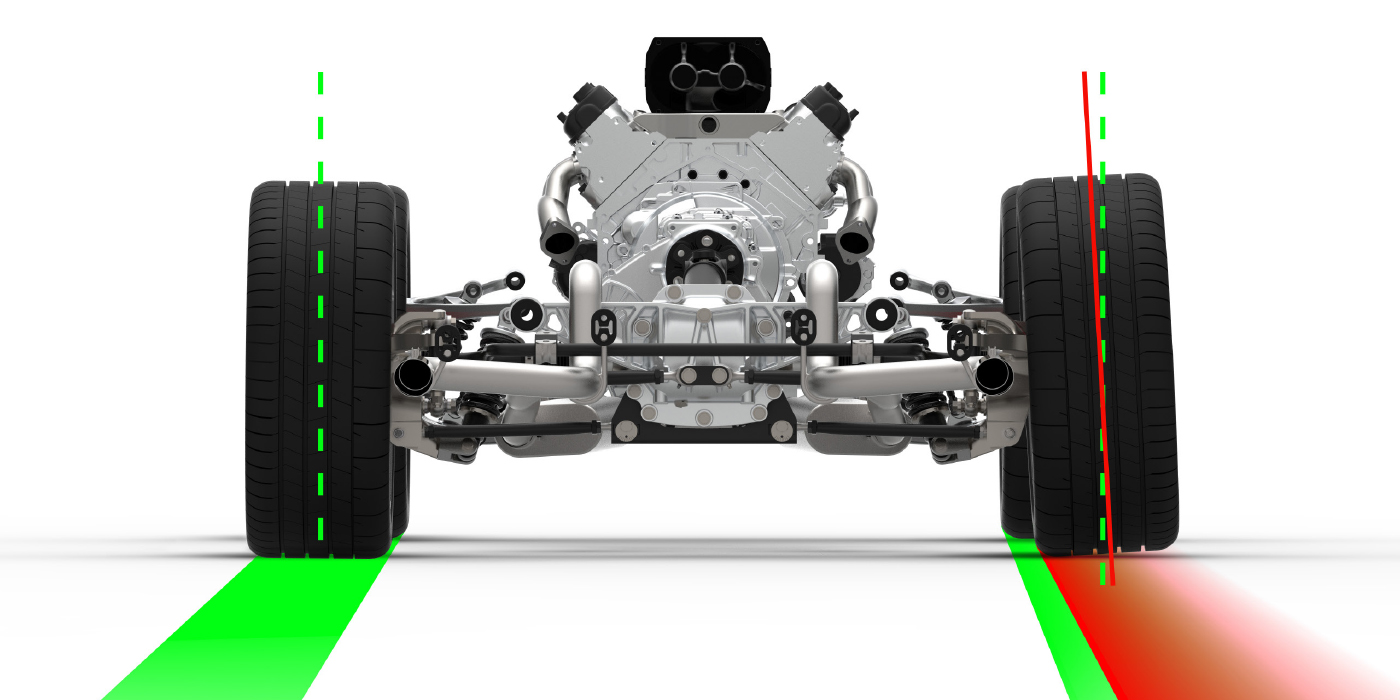

It’s as important to check tire pressures in the summer as it is in the winter – the National Highway Traffic Safety Administration estimates that 1 in 4 cars has at least one tire that is significantly underinflated. TPMS can help keep them aware of pressures, but tires can lose about 1 pound of pressure per month – and many cars don’t have built-in sensors.

The most important safety system on a vehicle is the driver – and if he or she can’t see properly due to damaged or underperforming headlights, emergency situations can get critical quickly. Headlight bulbs can have immediate and noticeable value to the customer, yet today’s cars often require significant time and effort to replace a bulb. Your customers may not have the tools or patience to perform replacements themselves – your shop may save the day…and the night.