The Volkswagen Touareg 2003-2010 was the first VW SUV and the first to get an air ride suspension system. The luxury SUV shares the same platform as the Audi Q7 and Porsche Cayenne. This is a full-feature air ride system, where the driver can control the height, designed to improve comfort, stability and off-road capabilities. Some vehicles with the 4XMotion option will also have a sway bar that can be decoupled to increase wheel travel. The struts have active dampeners that control compression and rebound. The air springs can be serviced separately from the dampeners. When there is a fault with the system, the system will display “Running Gear Fault” in the driver information center.

Compressor

The compressor is located under the left side of the vehicle next to the frame rail. It is a dry air compressor that will wear out over time. It supplies pressure to two reservoirs. One reservoir is located next to the compressor; the other is located in the rear of the vehicle.

The compressor is equipped with a temperature sensor. If excessive temperature is detected due to extended run times, the control module will deactivate the compressor to prevent damage.

Sensors

The system has four sensors that measure ride height. The system also has four accelerometers mounted to the body at the corners. The information from these sensors is used to determine the pressure in the air springs and the dampener settings. The information is also used for the active stabilizer bar and headlights.

The system has one pressure sensor that monitors the pressure at the valve block. Codesmight be related to the time it takes for the compressor to replenish the reservoir or the time it takes to carry out a trim adjustment. If it takes too long, the control module will assume there is a problem and puts the vehicle into a safe mode to preserve the compressor and airbags.

While these observations by the system could be the result of a leak, these faults are more likely the result of a weak compressor or sensor, or a problem with the solenoids controlling the system.

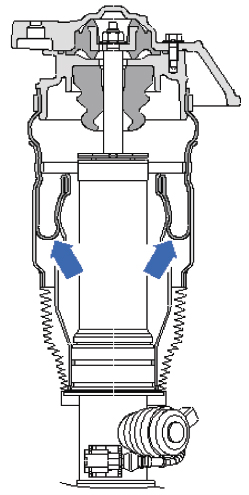

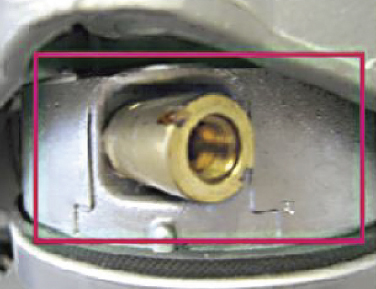

Residual Pressure Valves

Each air spring has a residual pressure valve at the top of the body. This valve keeps a minimum amount of pressure in the spring when the air spring is resting.

This valve can fail in two ways. First, it can leak and cause the air spring to collapse. Second, it can prevent air from escaping at one corner. Both conditions will result in a vehicle that looks slanted after it has been parked after a few hours. When restarted, the drive information display will have a warning for “Running Gear Fault.” Codes will be set in the air ride control module.

The residual pressure valves can be replaced separately from the air springs and requires a special socket to remove. The valves are prone to corrosion. Take your time removing them as they can snap off.

Testing the System For Leaks

In order to test the air suspension, the following conditions must be met:

- The vehicle must be cold and must not be moved during testing.

- The room temperature should be between 50-85º F, and remain steady.

- The vehicle must be sitting on a level surface.

- Start the engine.

- Adjust the suspension to the high level and then the normal level using the front information display.

- Turn off the engine.

- Disconnect the connector from the Level Control System Control Module (J197) on the right side of the rear cargo area to prevent the level control from readjusting.

- Measure vehicle height on all four wheels from the center of the wheel to the bottom of the wheel arch.

- After two hours, measure vehicle height again and compare the measurements. If the vehicle is sitting crooked, a leak is present at the suspension with the greatest difference between the first and second measurement.

- Check the affected air spring shock absorber and the corresponding air line using leak-detection spray in the following order:

- Air line connections (wiggle the lines to see if the problem leak is present).

- Residual Pressure Retaining Valve.

- Air spring.

8. If no deviation is determined after two hours, the measurement must be repeated after 24 hours. After 24 hours, a deviation of up to 4 mm is permissible.