Most entry-level VW models featured the same basic suspension used from the advent of the original VW Rabbit. About the only change was going from a rear strut suspension to a separate coil spring and shock absorber in the rear. Used for all models of the Golf, Jetta, New Beetle and the Audi TT, this suspension is simple, durable and easy to repair. There is still a beam axle in the rear of pre-2006 FWD cars.

For 2006, the A5 platform went to a multi-link rear suspension design that resembles the Ford Focus, right down to the blade-shaped upper control arms. The front suspension knuckles also resemble the Ford Focus design.

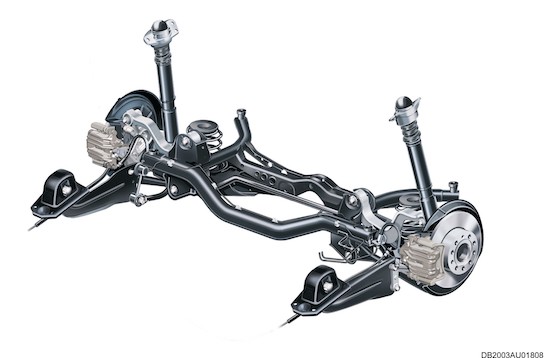

Beam Axles

Pay attention to the alignment angles, like toe and camber, for an indication of the health of the axle. Very few cases of corrosion have been reported with VW beam axles. The most common failure involves the bushings that connect the rear axle to the body. Bad bushings cause noise, thrust angle and setback problems.

Check the rear spring insulators for damage and dry rot. Also, make sure the lower bushings and upper shock mounts do not show wear or signs of bottoming out.

The majority of beam axle vehicles can be adjusted by inserting a shim between the axle and wheel bearing hub unit. This can offer some degree of adjustment. But, if the axle is way beyond adjustment, replacement is necessary.

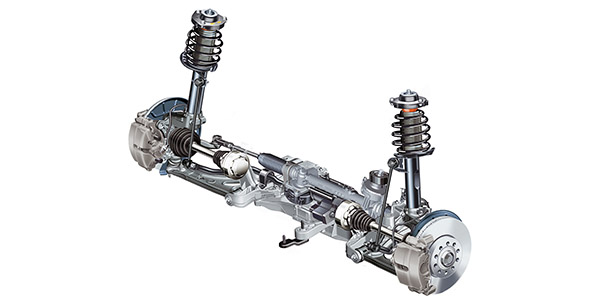

Multi-Link Rear Suspensions

The VW A5 platform for the Golf, Jetta and Audi TT abandoned the rear beam axle for a multi-link system with trailing and lateral links. The main wear points of the suspension are the bushings. Check for wear and any signs of movement in the outboard upper and lower control arms. As the bushings age, the extra compliance can cause the toe and camber angle to exceed specifications.

The A5 platform has an adjustment built into the rear suspension. An eccentric bolt on the upper control arm’s inboard mount controls the camber. The lower lateral link’s inboard bushing includes an eccentric to adjust the toe.

Front Suspension

In the front, all Jettas and Golfs have a very basic strut assembly with a lower control arm with two inner bushings and a bolted-on ball joint at the bearing carrier. Nothing could be simpler; even the sway bar is relatively easy to remove and install.

About the only weak points are the ball joints, as they are tiny and, with the additional horsepower, larger wheels, tires and brakes, they are prone to failure.

The fourth-generation platform was known to have problems with the suspension cradle shifting and changing the suspension angles. Often, the bushings are to blame. Some customers may complain of a popping or banging during turns in the footwell area. Oil and transmission fluid leaks can often cause the bushings to fail. Before replacing these bushings, make sure the leaks are resolved.

The A5 or fifth-generation platform also had suspension subframe complaints. The driver may also complain of popping or banging in the footwell area. The problem is often the fasteners that hold the subframe to the body. These bolts are torque-to-yield bolts that can work loose over time. This allows the subframe to move against the body and cause noise. If you see a case of this, it is recommended to replace the bolts and re-torque them using the proper procedure.

With every generation of the Jetta and Golf, the method of adjusting the camber has gone from easy to difficult to impossible. On pre-1998 vehicles, the camber could be adjusted by slotting the lower strut mounting bolts or by the use of a cam bolt. In 1999, VW said the camber was not adjustable, but could be changed slightly by moving the engine cradle. But, some aftermarket companies introduced upper strut mounts that could change the camber by ±1º. In 2006, the only way to change the camber was by shifting the subframe.

If you see a late-model VW with the camber out of specification, look for damaged parts first.

Steering Angle Sensors

After a minimal alignment, resetting the steering position sensor with a scan tool is not required. The lateral accelerometer and yaw sensor will compensate for minor changes in the steering angle after one drive cycle. If an extreme toe angle adjustment was performed, or if steering column and/or rack was replaced, performing a calibration procedure is required.

On vehicles with HID headlights, there is a link on the left front control arm that controls the angle of the lights depending on the attitude of the vehicle. The link is prone to damage and can detach. Always inspect this linkage and replace, if necessary. Also, the sensor can be calibrated with a scan tool.