Recently, I received a call from a technician who was about to go crazy from a TPMS problem. He did everything the right way using the correct service information to learn a new sensor. The customer said the light was on for a long time and one tire was going flat. One sensor had failed.

This service procedure required a test drive so the vehicle could learn the sensor IDs and position on the vehicle. He had checked the TSBs and even checked that the sensor IDs matched the ones in the TPMS module. All of the information was correct even with the IDs in the module. He was on his third test drive and the light would not go out.

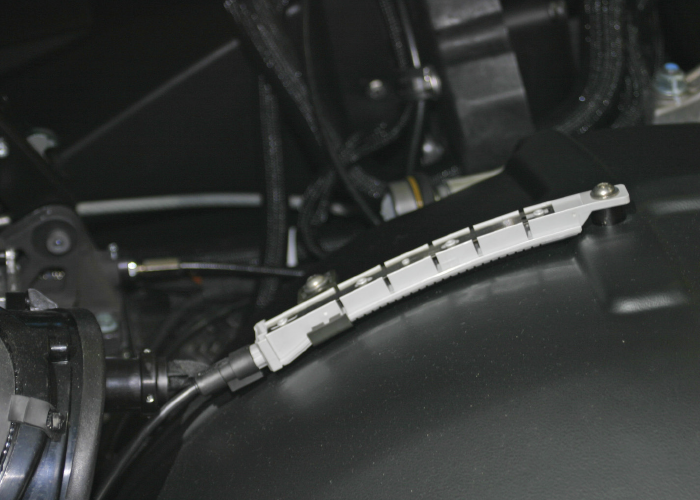

I had to ask what other things were wrong with the vehicle and if there were codes elsewhere in the vehicle. He said that the left rear had an ABS wheel speed sensor fault for erratic performance. On this vehicle, the wheel speed sensors and steering angle sensor had to be operating to perform the reprogramming procedure for a new sensor. The system uses the rolling circumference of the tire to set the pressure inside the tire. It also uses the wheel speed data to detect a blowout faster than a TPMS sensor.

When you think you know everything about TPMS systems, there will be a car or truck that pulls into your bays that will challenge all of your knowledge and diagnostic skills. It may not be a case of a mouse chewing a wire or poorly installed accessory – but rather how the manufacturer engineered the system.

Measuring the pressure inside a tire directly or indirectly is the easy part. Being able to turn a light on in the dash if a tire is low leaves engineers with a lot of different ways to accomplish the task.

DIRECT OR INDIRECT

You would think you could simply classify TPMS systems into two distinct categories of direct and indirect vehicles. Direct TPMS directly measures tire pressure and temperature with a sensor. Indirect systems use wheel speed sensors to measure the pressure indirectly.

But, there is a third type of system. BMW and Mercedes-Benz both use direct sensors in the tires, but also look at wheel speed sensor data as part of a flat tire detection system. The combined system can detect a blowout faster.

ANTENNAS

On most vehicles, there a single antenna for the four sensors. The antenna may be for only the sensors, or it could also be used for the keyless entry system. Why? The keyless entry system and TPMS sensors both transmit in the same radio frequency range of 315Hz to 430Hz.

Some vehicles have a dedicated module and antenna(s). And, some have four antennas in the wheel wells. Some Chrysler systems have three dedicated antennas, with the ignition switch module antenna acting as the fourth antenna. You probably won’t know that until you pull up the wiring diagram.

The signal from a TPMS sensor or key fob is a one-way conversation on most vehicles. The keyless entry fob or TPMS sensor transmits and the vehicle receives. Yes, some aftermarket replacement sensors and key fobs can be programmed wirelessly, but this is a different set of signals and antennas.

When a TPMS sensor or key fob transmits, it is a very dull, but fast (and important) conversation. It typically starts with an identification number that tells the module connected to the antenna to listen up. This code says the sensor or fob belongs to the vehicle. The next part of the transmission contains a command or status update on the tire pressure and temperature.

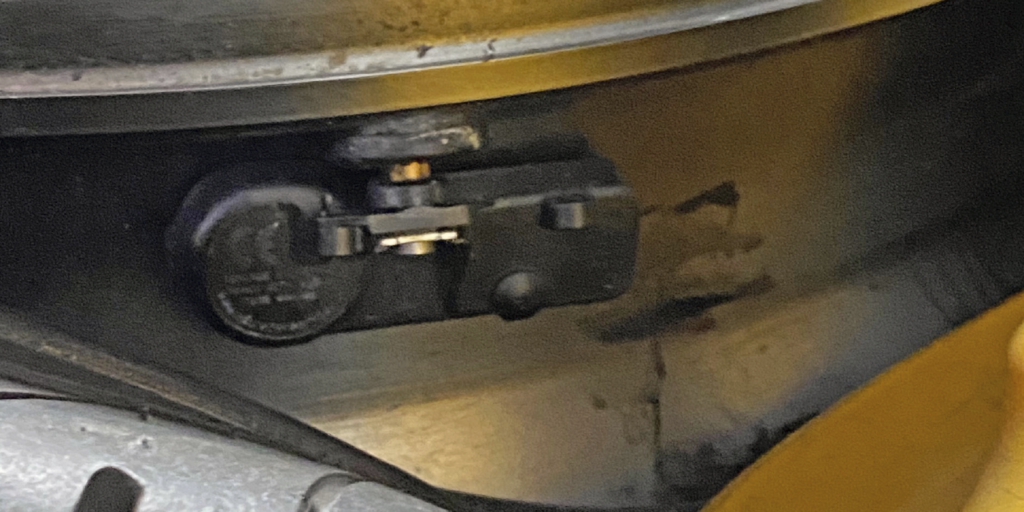

Just when you thought sensors do not receive signals, you find a system that has transmitters in the wheel wells. Instead of waiting for the sensor to transmit on its own, a transmitter in the wheel well will send a signal to a sensor at around 125Hz. The signal tells the sensor to transmit a signal. The main advantage of this type of system is the individual pressures can be obtained when the vehicle is stationary.

While this type of knowledge is not required to determine if a sensor is not functioning, it might prove to be essential when diagnosing a problem where data from one corner is not making it to the module.

TPMS MAPPING, MODULES AND THE LIGHT

Once the antennas, sensors or wheel speed sensors have detected a low-tire condition, it has to be communicated to the driver. This is done with a light in the dash and/or a message in the driver information display. The information can take several routes and pass through different modules.

Most TPMS systems have the antenna connected to the keyless entry module. Some systems have a dedicated TPMS module. But, the command to turn on the light may go through a body control module. Some vehicles have TPMS modules that communicate on a serial data bus with the instrument cluster or combination meter module.

But, then, an automaker can throw you a curveball. Some early systems have the TPMS lights in the instrument cluster that are directly wired to the module.

Finding how the sensors communicate with the light is a critical step for situations where the system is not functioning or is causing DTCs in other modules. Sometimes, the root cause of a TPMS problem is not the TPMS module or sensors, but it could be the network or the modules on the network.

DIAGNOSTIC PATH

I believe in the “Test Before You Touch” method as a way to perform triage when assessing the initial customer complaint. This procedure can rule out inflation and dead sensor problems. But, if the problem can’t be resolved, it requires looking at the service information and TSBs.

Your TPMS tool is not just for relearns and programming sensors. Many of these tools can pull codes from the TPMS module through the OBDII connection. They can also be used to detect and measure the strength of radio signals coming from sensors and the environment around the car.

Many TPMS systems are more than a decade old. With older vehicles, there are more curveballs. During the first years of the TPMS mandate in 2007 and 2008, many manufacturers were still trying to integrate TPMS sensors, antennas and modules onto pre-existing platforms. These single-model exceptions are where you might have to be a diagnostic switch hitter. Bottom line: Never assume that all TPMS systems operate the same way.